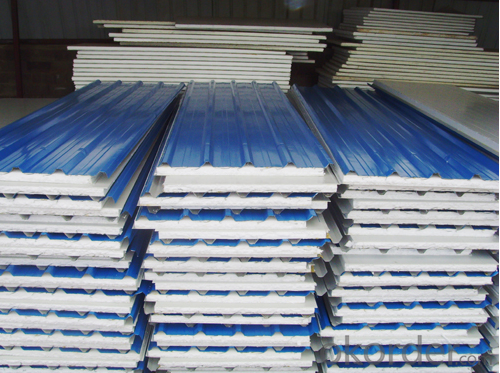

Hot-Dip Galvanized Steel/Pre-Painted Steel Coil for Tiles Width 1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

APPLICATION: commodity Brick pattern Color Galvanized Steel Sheet (PPGI/ PPGL) Techinical Standard: JIS G3312-1998, EN101169, ASTM A755 grade TSGCC, TDX51D / TDX52D / TS250, 280GD Types: For general / drawing use Base metal galvanized, galvalume Thickness 0.14-3.0mm(0.16-0.8mm is the most advantage thickness) Width 610/724/820/914/1000/1200/1219/1220/1250mm Type of coating: PE, SMP, PVDF Zinc coating Z60-275g/m2 or AZ40-150g/m2 Top painting: 5 mic. Primer + 15 mc. R. M. P. Back painting: 5-7 mic. EP Color: According to RAL standard ID coil 508mm / 610mm Coil weight: 4--8MT Package: Properly packed for ocean freight exportation in 20' ' containers Application: Industrial panels, roofing and siding for painting / automobile Price terms FOB, CFR, CIF Payment terms 20%TT in advance+80% TT or irrevocable 80%L/C at sight delivery time 25 days after recepit of 20% TT Remarks Insurance is all risks MTC 3.1 will be handed on with shipping documents We accept SGS certificatation test PPGI,(PPGL,pre-painted galvanized steel coils, pre-painted galvalume steel coils,color coated steel coils.color coated galvanized steel coils)

Exterior decoration of buildings: Roof and wallboards of industrial, commercial, residential and public facilities

Interior decoration of buildings: Wallboards, ceiling boards, partition boards, fireproof doors

Building accessories: Window panels, signboards

Home appliances: Oil/gas boilers, rice buckets, portable gas burners, etc.

Prime CGCC RAL DX51D Z60 Z100 Color Coated Steel/ PPGI/Color Prepainted Galvanized Steel Coil(China)

FOB Price: US $630 - 938 / Ton Get Latest Price

Min. Order Quantity: 15 Ton/Tons

Supply Ability: 5000000 Ton/Tons per year

Port: Qingdao, Tianjin, China

Payment Terms: L/C, T/T, Western Union

Contact Supplier

Company Information

Quick Details

Standard: AISI, ASTM, BS, DIN, GB, JISGrade: SGCC SGCD SGCH DX51D/52D/53DThickness: 0.22-1.0 mm

Place of Origin: Tianjin China (Mainland)Model Number: CGCC CGCL PPGI PPGLType: Steel Coil

Technique: Cold RolledSurface Treatment: CoatedApplication: Container Plate

Special Use: Wear Resistant SteelWidth: 750-1250mmLength: Coil Or Sheet (780-6000 mm ) can be done as your requirements.

Exporting Ability: 500 20ft container/each monthZinc Coating: Z40--Z180g/m2Painting: Front side paint thickness: 15-25μ M (bottom paint + top paint)

Sample: Offer Free Sample For Quality TestContainer Info: One 20ft container can hold 26tons MaxColor: As the RAL color chart

Coil I. D: 508/610 mmCoil Weight: 3.5-8 tons/each coilOther Poducts: Cold rolled, galvanized steel coils

1, Introduction: PPGI is made of galvanized steel coils or galvalume steel coils with polymer coatings as surface. It's a new enclosure material and building board

2, Product feature: Apperance of a variety of color Antirust and antiseptic,durability,etc.

3, Production Process: Pretreatment(Degreasing) DryingChromatingPaint Basic OilCoolingDryingColor CoatingCoolingFilm- coveringRolling Up

4, Application: it is ideal for a wide range of applications,, such as pre-engineered buildings, architectural panels, roofing, siding, cladding, and many other building components.and also used back plate of appliance; wide range of construction, furniture industry, transportation industry, etc.

FAQ

1.Are the products tested before shipping?

Yes, all of our PPGI and GI was qualified before shipping. We test every batch every day.

- Q: How are steel coils used in the production of agricultural systems?

- Steel coils are often used in the production of agricultural systems due to their durability and strength. These coils are typically used in the construction of machinery and equipment that are essential in agricultural operations. One common application of steel coils is in the manufacturing of farming machinery such as tractors, plows, and cultivators. These machines require sturdy components to withstand the demanding conditions of the agricultural environment. Steel coils are used to fabricate the frames, chassis, and other structural parts of these machines, providing the necessary strength and support. Steel coils are also used in the production of irrigation systems, which are crucial for efficient water management in agriculture. These coils are utilized in the construction of pipes, valves, and fittings, ensuring the durability and longevity of the irrigation system. Additionally, steel coils are used to manufacture storage tanks and silos, which are essential for storing and preserving agricultural products such as grains, seeds, and fertilizers. Furthermore, steel coils find application in the construction of greenhouses and agricultural buildings. The coils are used to fabricate the structural framework, providing stability and resistance against environmental factors. Steel coils are also used in the production of fencing and enclosures to protect crops and livestock from external threats. In summary, steel coils play a vital role in the production of agricultural systems by providing the necessary strength, durability, and stability required for farming machinery, irrigation systems, storage facilities, and agricultural structures. Their usage ensures that these systems can withstand the demanding conditions of the agricultural industry and contribute to efficient and sustainable farming practices.

- Q: How do steel coils compare to other materials in terms of strength?

- Steel coils are renowned for their remarkable strength and durability, rendering them among the most robust materials obtainable in the market. In comparison to alternative materials like aluminum or plastic, steel coils demonstrate unparalleled strength and resilience against deformation or breakage. Due to the elevated tensile strength of steel, coils can withstand substantial loads, thereby rendering them perfect for diverse industrial uses, encompassing construction, automotive manufacturing, and the production of heavy machinery. Moreover, steel coils possess exceptional fatigue resistance, enabling them to endure repetitive stress and strain without compromising their structural integrity. This strength advantage positions steel coils as the preferred choice for applications that prioritize reliability and safety.

- Q: Is Carbon Steel strong for swords?

- Depends on the sword design. Some swords are high carbon, some a low carbon, some are made from a billet of alternating high and low carbon ('Damascus' steels). It all depends on what characteristics you want for your sword. Softer steels won't hold an edge as well but they offer great flexibility so your sword won't shatter when they make impact with armor or shields. Harder steels hold better edges but they're prone to binding in wooden shields and then being broken as soon as a bending force is applied along the weak axis of the blade. Japanese Katanas have both hard and soft steels to allow the blade to bend yet still hold strong edges. If you're making the sword from raw materials on your own, look up some different recipes for crucible steel. It's probably the most fun and involved process.

- Q: I want to get a new knife but i cant decide if i wan a spyderco pacific salt or a cold steel ak47

- What exactly are you using it for? Personally I would go with Cold Steel AK47. It's a good all around knife for hunting, combat, stabbing and slashing as well as everyday use. Well balanced tip and very little bladeplay which can be a problem with a cheaper knife. Both are good companies but the CS AK47 wins hands down for me.

- Q: Me and my cousin have been arguing about this. I said that superman is made out of steel, but he says that people just call him the man of steel because he's hard like steel. Does he have steel in his body?

- Superman has no steel in his body. When Superman was called The Man of Tomorrow, which was many years ago, he wasn't made of tomorrow.

- Q: Guitar?I have a steel- string, but prefer nylon.:)

- Steel string 4 playing wid plectrum, nylon 4 finger style playing

- Q: What are the different types of steel coil surface treatments for indoor applications?

- There are several different types of steel coil surface treatments that are suitable for indoor applications. These treatments are designed to enhance the appearance, durability, and performance of the steel coil in various indoor environments. Some of the common surface treatments for indoor applications include: 1. Galvanized Coating: This is one of the most popular surface treatments for indoor applications. Galvanizing involves applying a layer of zinc to the steel coil, which provides excellent corrosion resistance and protects the steel from environmental elements. 2. Pre-painted Coating: Pre-painting the steel coil with a specific color or finish is another common surface treatment for indoor applications. This coating not only improves the aesthetics of the steel, but also provides additional protection against corrosion and wear. 3. Powder Coating: Powder coating is a process where a dry powder is electrostatically applied to the steel coil and then cured under heat. This treatment creates a durable and attractive finish that is resistant to chipping, scratching, and fading. Powder coating is available in a wide range of colors and textures, making it a versatile choice for indoor applications. 4. Vinyl Coating: Vinyl coating is a type of surface treatment that involves applying a layer of PVC (polyvinyl chloride) to the steel coil. This coating provides excellent chemical resistance and protects the steel from moisture, abrasion, and UV radiation. Vinyl coating is commonly used in indoor applications where chemical exposure or moisture resistance is a concern. 5. Laminated Coating: Laminating the steel coil involves bonding a thin layer of plastic or other material to the surface of the steel. This treatment enhances the appearance of the steel and provides additional protection against scratches, stains, and fading. Laminated coatings are available in various colors and patterns, making them suitable for indoor applications where aesthetics is a priority. It is important to consider the specific requirements of the indoor application when choosing a steel coil surface treatment. Factors such as corrosion resistance, durability, aesthetics, and budget should be taken into account to ensure the best possible performance and longevity of the steel coil in indoor environments.

- Q: How are steel coils used in the production of automotive suspension systems?

- Steel coils are used in the production of automotive suspension systems as they provide the necessary support and flexibility to absorb shocks and vibrations. These coils are typically used in the construction of coil springs, which are then integrated into the suspension system to ensure a smooth and comfortable ride for the vehicle.

- Q: What are the different types of steel coil finishing processes?

- There are several different types of steel coil finishing processes that are used to enhance the appearance and properties of the steel coils. Some of the common types include: 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc, which creates a protective layer on the surface of the coil. This not only enhances the corrosion resistance of the steel but also provides a smooth and visually appealing finish. 2. Cold rolling: Cold rolling is a process in which the steel coil is passed through a series of rollers at room temperature to reduce its thickness and improve its surface finish. This process can impart a variety of finishes, ranging from a matte to a highly polished surface. 3. Electro-galvanizing: In this process, a thin layer of zinc is applied to the surface of the steel coil through an electrolytic deposition. Electro-galvanizing is commonly used for applications that require a thinner zinc coating and a more uniform finish. 4. Pickling and oiling: Pickling involves treating the steel coil with an acid solution to remove any scale or surface impurities, resulting in a clean and smooth surface. After pickling, the coil is usually coated with oil to prevent rusting during storage and transportation. 5. Powder coating: Powder coating is a popular finishing process that involves applying a dry powder to the steel coil and then curing it under heat to form a durable and attractive finish. This method allows for a wide range of colors and finishes to be applied to the steel. 6. Paint coating: Similar to powder coating, paint coating involves applying a liquid paint to the surface of the steel coil. This process can provide a decorative finish while also offering protection against corrosion and other environmental factors. These are just a few examples of the different types of steel coil finishing processes. The choice of the finishing method depends on the specific requirements of the application, such as the desired appearance, corrosion resistance, and durability.

- Q: I'm looking for steel to make knives, but don't know what to get.

- that's a hard one, right here is why. once you like a truck you do no longer want a Porche and vice versa. In different words have been one steel excels the different is unfavorable. For overallstrengthh i like 5160, for organic area retaining i like D2, O-a million and 52100 are probable the appropriate carbonsteel in area retaining. in case you like a knife with corrosion resistance then stainless is the appropriate determination. yet stainless needs to cryo dealt with to benefit the finished skill of the steel. I don'trecommendinless for any blade over 5 as a results of fact the greater desirable grain shape won't be able to take flexing and could wreck. For a heavy accountability super knife I recomend carbon steel with a differential temper as carried out good it may flex without breaking. What does all this mean? the appropriate steel is not any further effective than a decrease high quality steel if there's a deffitiancy in warmth therapy or layout. D-2 has not greater reducing potential than 440c at 57r. i do no longer use stainless in my knives as they're puzzling to warmth manage, D-2 case in point, fifty deg. in the two direction from the hardening temp (which ought to be held for minimum of 20-half-hour) can mean 2 factors Rockwell. All stainless are this type, as such maximum manufactures in no way comprehend the potetiel of the steel. right here is what i exploit, on a small knife have been i want greater effective area retaining from a greater durable temper (60r) i like O-a million, W-a million and 52100. For greater desirable knives L-6 works properly. For a survival/attempt against knife 5160 is my determination. those are not the only steels accessible, the books are full of them. solid luck.

Send your message to us

Hot-Dip Galvanized Steel/Pre-Painted Steel Coil for Tiles Width 1250mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords