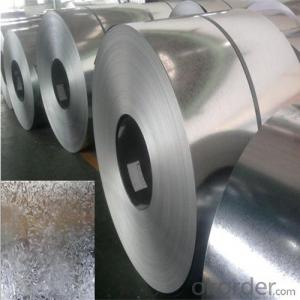

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details | |||||

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC,DX51D/DX52D/S250,280GD | Thickness: | 0.12-4.0 mm |

Place of Origin: | China (Mainland) | Brand Name: | N/M | Model Number: | ssp-226 |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | galvanized/ Galvalume/zinc coatting |

Application: | strong anti-corrosion ability,cold bending molded manufacturablity | Special Use: | High-strength Steel Plate | Width: | 600-1250 mm |

Length: | in coil | product: | g40 prime/secordary hot-dip galvanized cold rolled steel coil/sheet | ||

Packaging & Delivery | |||||

Packaging Detail: | standard export package,Other types of packing can be customized as per client's requirement. | ||||

Delivery Detail: | as per client's requirements | ||||

Specifications

1.Mateials:SGCC,DX51D / DX52D / S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

7. Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

8.Packaging Details:

Standard export package.

Other types of packing can be customized as per client's requirements.

- Q: What are the different methods of painting steel coils?

- There are several methods of painting steel coils, including coil coating, spray painting, and powder coating. Coil coating involves applying a liquid coating to the surface of the steel coil, which is then cured and dried. Spray painting involves using a spray gun to apply paint to the coil, typically in multiple layers. Powder coating involves electrostatically applying a dry powder to the coil, which is then cured and fused onto the surface. Each method has its advantages and is chosen based on factors such as durability, cost, and desired finish.

- Q: How can I arbitrate quality of steel before purchasing it??

- The quality of the alloy can be very well be judged by its appearance and lustrous surface. The more luster on the surface the more refine will the steel be. To judge its tenacity and endurance, the alloy can be subjected to a series of procedures involving stress and shock. The reaction to these processes can determine whether the steel be fit for the purpose required.

- Q: How are steel coils coated to prevent corrosion?

- Steel coils are often coated to prevent corrosion through a process called galvanization. This involves applying a layer of zinc to the surface of the steel coils, which acts as a protective barrier against moisture and other environmental elements. The zinc coating effectively prevents rust and corrosion from forming on the steel surface, extending the lifespan of the coils.

- Q: What is the difference between hot rolled and cold rolled steel coils?

- The main difference between hot rolled and cold rolled steel coils lies in the manufacturing process. Hot rolled steel coils are produced by heating the steel to high temperatures and then rolling it while it is still hot. This process results in a rougher surface and less precise dimensions, but it makes the steel more malleable and easier to shape. On the other hand, cold rolled steel coils are manufactured by cooling the hot rolled coils and passing them through a series of rollers at room temperature. This process produces a smoother surface and tighter tolerances, making it suitable for applications that require precise dimensions and a higher quality finish.

- Q: How are steel coils used in the manufacturing of shipbuilding?

- Steel coils are used in shipbuilding for several purposes. They are primarily used to fabricate the hull and structural components of ships. Steel coils are cut, shaped, and welded to form various ship sections, such as the hull plates, bulkheads, and decks. These coils provide the necessary strength, durability, and corrosion resistance required for marine applications. Additionally, steel coils are also used to manufacture other shipbuilding components like piping, machinery, and equipment, ensuring the overall integrity and functionality of the vessel.

- Q: How are steel coils used in the production of steel clamps?

- Steel coils are used in the production of steel clamps as they provide a continuous supply of high-quality steel material. These coils are unwound and processed through various manufacturing steps, such as cutting, shaping, and forming, to create the desired shape and dimensions of the steel clamps.

- Q: Are Steel Building Kits really helpful while erecting a steel building?

- Of course yes! Steel building kit is design specific corresponding to the type of steel building required to be constructed or erected. The steel building kit consists of all the necessities needed by the purchaser or the investor. As steel buildings are prefabricated or pre-engineered they are manufactured in factories in various sections and parts which are to be brought to the construction site to be assembled. So in any case they are beneficial :)

- Q: I need steel toe shoes for a workplace, where can I get them?I live in Surrey,UK.

- steel okorder

- Q: What are the different types of steel coil edge conditions?

- The different types of steel coil edge conditions include mill edge, slit edge, and deburred edge.

- Q: How did the growth of the steel industry influence the development of other industries?

- At least three ways: 1. Steel as a material that other industries could use to do things that couldn't be done before (for example, construction (skyscrapers, long bridges, etc.)) or could now be done at much lower cost and hence increased the size of the industry (automobiles, bearings, etc.)

Send your message to us

HOT-DIP GALVANIZED STEEL COIL WITH SUPER HIGH QUALITY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords