Hot Dip Galvanized Steel Coil Sheet with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

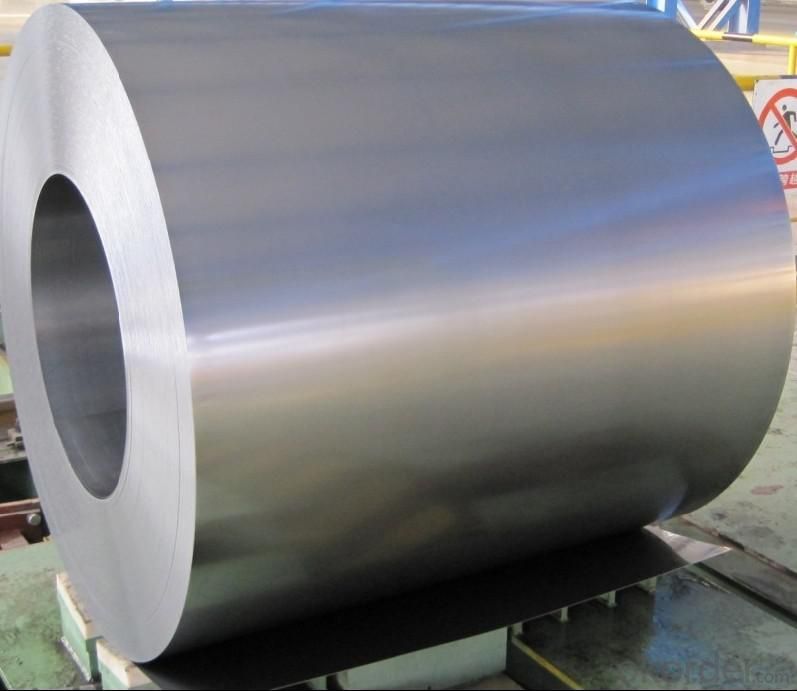

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

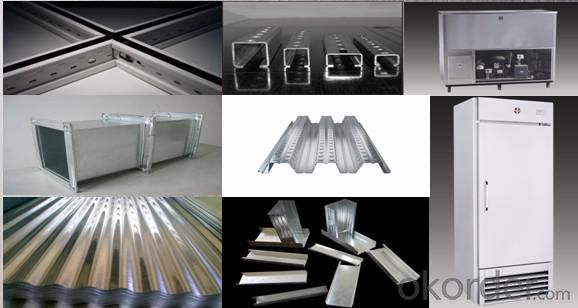

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

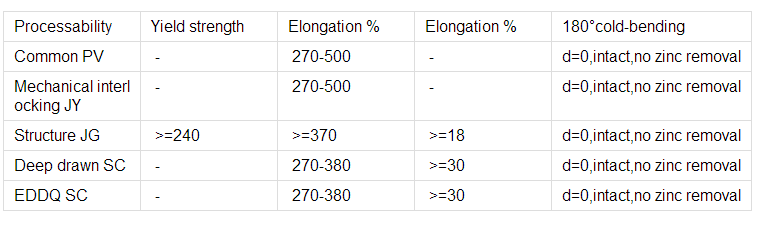

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: in a lab at school we did heat treatment of steelwhat are the possible phases present in the steel sample in as-received, as-quenched and as-tempered conditions? specifically when is it ferrite, austenite and pearliteis the steel originally in the ferrite phase? then when headed turns into austenite and when quenched martensite is formed and when tempered cermentite is formed...........where is pearlite involved and am i correct about the ferrite?

- hey from what i learned in uni last sem, steel is originally ferrite form at first at room conditions. it will undergo poly morphic transformation to become FCC structure austenite form at 912 degree celcius. under conditions, it can become pearlite (which is a combination of ferrite and cementite) or bainitie( a finer form of pearlite). queching conditions to room temperature will form martensite which is the strongest but brittle steel form. tempered cementite is formed when we quench it and then raise temperatures before sir cooling. hope it helps, pls vote me best answer is i deserve it. thanks

- Q: How are steel coils used in the HVAC industry?

- Steel coils are commonly used in the HVAC industry for various purposes such as heat transfer, refrigerant circulation, and air conditioning. They are typically found in heat exchangers, condensers, and evaporators, where they help in transferring heat between air and refrigerant. Steel coils play a crucial role in maintaining the desired temperature and providing efficient cooling or heating in HVAC systems.

- Q: so i've started learning to play guitar in the past few weeks, and i'm using my sister's old guitar which isn't in very good condition, so i'm planning on buying a new one, but which would be better to buy, nylon string or steel string?

- It rather relies upon on what type of music you're enjoying, nylon string guitars have a mellow, softer tone than steel strings, the feel of the nylon strings (a minimum of to me) are reliable, in my opinion, i might ought to declare nylon is extra suitable, large for finger choosing and a effective tone. once you're searching for a guitar, you are able to flow out to a close-by guitar save, and attempt the two out for your self, in straight forward terms then will you comprehend for specific.

- Q: How are steel coils used in the production of metal cladding?

- Steel coils serve as the primary raw material for metal cladding production. Metal cladding involves covering a building's exterior with a layer of steel to enhance its durability, aesthetics, and insulation. To begin the manufacturing process, galvanized steel coils are used. These coils are made by coating steel with zinc to prevent corrosion. They are then unrolled and fed into a roll-forming machine, which shapes them into the desired profile for the cladding panels. Once the coils are formed, they undergo various processes to improve their properties. These processes include cutting, perforating, and embossing to create patterns, textures, or openings in the panels. Additional protective layers, such as paint or powder coating, can also be applied to enhance corrosion resistance and appearance. The shaped and processed coils are assembled into metal cladding panels. These panels interlock seamlessly to create an appealing exterior for buildings. They can be attached to the building's structure using screws, clips, or adhesives. Using steel coils in metal cladding production offers several advantages. Steel is a strong and durable material, making it suitable for exterior applications that require resistance to weathering, impact, and other environmental factors. It also allows for a wide range of design options and customization. In summary, steel coils are essential in the production of metal cladding. They serve as the raw material, which is shaped, processed, and assembled into panels that enhance buildings' protection, aesthetics, and insulation properties.

- Q: How are steel coils used in the production of industrial boilers?

- Steel coils are used in the production of industrial boilers to form the main body and components of the boiler, such as the shell, tubes, and headers. The coils are shaped and welded together to create a strong and durable structure that can withstand high pressure and temperature conditions. Additionally, the use of steel coils ensures the boiler's efficiency and longevity, as steel is known for its excellent heat transfer properties and resistance to corrosion.

- Q: How are steel coils used in the production of steel washers?

- Steel coils are used in the production of steel washers by being uncoiled and fed into a stamping machine. The machine then cuts and shapes the steel into individual washer blanks. These blanks are then further processed and finished to create the final steel washers.

- Q: My uncle got me some new 'Nam style jungle boots at the px at Fort Worth JSB, and he told me that back in Vietnam, they used to issue guys steel sole boots, that had a sole reinforced with a steel plate, as punji stick d-fence. Is this true, it sounds logical, but I can't figure out how a steel plate in the sole would work. My uncle is kind of a BS'er, plus he wasn't even in Vietnam, much less the Infantry, much less combat, but he was in USAF at the time.

- The issue of steel soled boots in Vietnam did actually happen. The steel plate is in the mid-sole, to prevent punji sticks (or other sharp objects) from penetrating the boot if you stepped down on them. These bamboo or metal spikes - often coated with human excrement - were placed in shallow (camouflaged) pits dug in the ground or sometimes under water at places where you'd ford a stream. Quite apart from the physical injury from stepping on one, there was a high risk of serious infection from what they were coated with. Originally the steel plate was issued as an insole to go inside but that give the soldiers blisters, so later the boots were manufactured with it as part of the sole. Steel toe-cap boots containing a mid-sole plate are sold today for use by builders and construction workers who have a similar risk of stepping on nails, screws, glass, etc.

- Q: Where are the coils and the steel plates used? Where did the steel plate come from?

- Steel coil is a kind of steel plate, also known as coil.The coil, like toilet paper, can roll into a barrel. (describe not very appropriate)When the coil is used, it is necessary to use the Kaiping machine to expand into a flat plate.

- Q: What are the typical lead times for steel coil orders?

- The typical lead times for steel coil orders can vary depending on factors such as the quantity, specifications, and availability. However, on average, lead times can range from a few weeks to several months. It is recommended to check with the specific supplier or manufacturer for accurate lead time estimates.

- Q: What are the different methods of edge trimming for steel coils?

- There are several methods of edge trimming for steel coils, depending on the specific requirements and application. Some of the common methods include: 1. Slitting: This is one of the most common methods used to trim the edges of steel coils. It involves passing the coil through a set of circular knives that cut the edges into narrower strips. Slitting can be done in-line during the manufacturing process or as a separate operation. 2. Shearing: Shearing is another popular method used for edge trimming. It involves using a set of blades to cut the edges of the coil in a straight line. Shearing is often used when precise and clean cuts are required, and it can be done manually or with the help of automated machinery. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser to trim the edges of steel coils. This method provides precise and smooth cuts, and it is often used when high accuracy and quality are essential. Laser cutting can be incorporated into the production line or performed as a standalone process. 4. Grinding: Grinding is a method that involves using abrasive wheels or belts to remove material from the edges of steel coils. It is commonly used to remove burrs, rough edges, or surface imperfections. Grinding can be done manually or with the help of automated machines, depending on the scale and complexity of the trimming process. 5. Waterjet cutting: Waterjet cutting is a method that utilizes a high-pressure jet of water mixed with abrasive particles to trim the edges of steel coils. This method is known for its versatility and ability to cut through a wide range of materials and thicknesses. Waterjet cutting is typically used when complex shapes or intricate designs need to be achieved. Overall, the choice of edge trimming method for steel coils depends on factors such as the desired accuracy, speed, complexity of the edges, and the specific requirements of the application. Different methods offer varying levels of precision, efficiency, and cost-effectiveness, allowing manufacturers to select the most suitable technique for their specific needs.

Send your message to us

Hot Dip Galvanized Steel Coil Sheet with High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 80000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords