Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm:

1) Standards: JIS G3302 1998 / ASTM A653M / A924M 1998/ DIN EN10143/GBT 2518-2008

2) With excellent weather resistance

3) Suitable for partitions, vending machinery, decks, scaffolding, purlin, gurdrail, suspension bar for ceiling and so on

4) Specification: SPCC, SGCC, SGCH, SGCD, SGHC, (CS, SS, DDS)

5) Thickness: 0.14mm-50mm

6) Width: 20mm - 1250mm

7) Zinc coating: Z08, Z12, Z18, Z20, Z22, Z25, Z27.Z100

8) Surface finish: Regular spangle, minimized spangle, zero spangle

9) Surface treatment: Chromating treatment, anti-finger print

10) Inner diameter: 508mm / 610mm

11) Outer diameter: 2, 000mm max .

2.Specifications of Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm:

Steel Grade : SPCC SGCC DX51D Q235 Q195

Type : Steel Coil

Surface Treatment : Galvanized

Technique : Cold Rolled Or Hot rolled

Tianjin,China

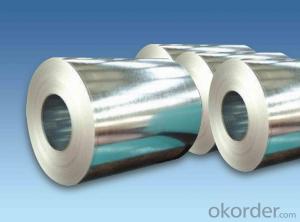

3.Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm Images:

4.Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm Specification:

Base metal | Cold rolled steel coil,full hard cold rolled steel coil,Black cold rolled steel coil |

Material | DX51D+Z,CSB,S280GD,S320GD,S350GDSGCC |

Grade: | Commercia.Quality(CGCC,DX51D,DC01,SPCC), Structure.quality(S280GD,S320GD,S350GD). Deep.drawing.quality(DX52D,DX53D,DX54D,DX56D) |

Standard | ASTM A653 CS/B,JIS G3302,DIN EN 10142,EN10327 |

Applications | Advertising,building trade,home electrical, Electrical industry,decoration,office furniture |

Thickness | 0.18mm-1.5mm |

Tolerance | +/-0.03mm |

Zinc layer | A40,A60,G60,G90,G115,G140,G165. Z12,Z18,Z22,Z25,Z27,Z35. Z60,Z80,Z100,Z120,Z150,Z180,Z220,Z275,Z350 |

Width | 600mm,750mm,762mm,914mm,1000mm,1219mm,1200mm,1250mm,1500mm |

Length | 1.5m,2.0m,2.438m,2.44m,2.5m,3m.,3.5m,4m,4.5m,5m |

Surface treatment | Chromated,oiled/unoiled,skinpassed,Chromated+oiled |

Surface state | Regular spangle,mini spangle,zero spangle, skinpassed |

Coil weight | 4-8tons |

ID | 508mm or 610mm |

Packing | Export standard seaworthy packing. Waterproof paper+steel sheet+bundle with steel strips(3-4pcs) |

Delivery | Based on the quantity. |

Shipment | Bulk vessel or container (FCL/LCL) |

Payment | T/T or LC at sight |

Loading port | Main port of China,Shang hai,Qingdao,Dalian,Tianjin etc. |

Yield strength | 285Mpa-305Mpa |

Tensile strength | 340Mpa-370Mpa |

5.PACKING:

6.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: What are the different methods of transporting steel coils?

- Depending on factors such as weight, size, and distance, there are various methods available for transporting steel coils. These include: 1. Flatbed trucks: Steel coils can be transported on flatbed trucks, which have a spacious open platform for easy loading and unloading. This option is commonly used for shipments of short to medium distances and provides convenient access to the coils. 2. Rail transport: Steel coils can also be transported by rail using specialized coil cars with curved interiors to securely hold the coils. Rail transport is often preferred for long-distance shipments due to its cost-effectiveness and capacity to handle large quantities. 3. Shipping containers: Steel coils can be loaded into shipping containers for transportation via sea or inland waterways. To prevent movement during transit, the coils are usually secured inside the container using bracing or blocking materials. This method is commonly employed for international shipments and facilitates easy handling and transfer between different modes of transportation. 4. Barges: In some cases, steel coils can be transported on barges along rivers, canals, or other inland waterways. Barges are particularly suitable for large and heavy shipments, offering a cost-effective and efficient means of transportation. 5. Roll-on/roll-off (RoRo) vessels: RoRo vessels are specialized ships designed to transport vehicles and large cargo that can be rolled on and off the ship. Steel coils can be loaded onto trailers or flatbeds and driven onto the vessel, providing a convenient transportation option. 6. Air freight: Although less common due to higher costs, steel coils can also be transported by air. This method is typically used for urgent and time-sensitive shipments or when the distance is too great for other modes of transportation. Air freight offers the advantage of speed and can be a viable option in certain situations. In conclusion, the choice of transportation method for steel coils depends on factors such as cost, distance, time frame, and logistical requirements. Freight forwarders and logistics providers can assist in determining the most suitable method for a specific shipment.

- Q: i always have eaten rolled oats and i have never tried steel cut oats. what are your opinions on them for oatmeal and which do u like better?

- Steel cut oats, much better texture. You can prepare them overnight in a mini-crockpot with raisins, brown sugar, nuts or anything you like in your oatmeal. You can also put steel cut oats and all your favorite oatmeal toppings in a stainless steel thermos with boiling water overnight. Either way it will be hot and ready to go in the morning. Have a great day!!

- Q: what pokemon are week to steel type pokemon like lucario? help please, and thank you.

- Hi! well i hav both games but ther's no big difference. I play Diamond more though. For starter u shud pick piplup: 1. because u love water pokemon of course 2. piplup is stong against chimchar (water- fire) 3. it can learn ice moves like ice beam which are super effective against torterra. 4. Empoleon looks Wicked!! and its steel type backs up its weaknesses. i liked it. hav fun with the game!!!!!!!

- Q: Can steel coils be coated with self-cleaning materials?

- Yes, steel coils can be coated with self-cleaning materials. These materials are typically hydrophobic or photocatalytic coatings that help prevent dirt, dust, and other contaminants from sticking to the surface of the steel. The self-cleaning properties of these coatings allow for easier maintenance and longer-lasting aesthetics of the steel coils.

- Q: I want to experiment with making steel and want to especially make it stronger. And also I want to know if its possible to turn a meteorite into steel?

- If you really want to do this, you should be getting some books on steel metallurgy rather than asking on Yahoo. ASM sells a Metallurgy for the non-metallurgist that would be a good introduction. Most university libraries will have the full ASM handbook that includes detailed information for different grades of steel (vol 1), heat treatment and surface hardening (vol 4), testing (vols 8-12), and casting (vol 15). A reference for continuous cooling transformation diagrams will also help in designing a heat treatment process. If you want to make something stronger than most commercial steels, you'll need to get into nanotechnology and unconventional steel processing methods like powder metallurgy. You can increase the strength of steel by about 1000% by reducing the grain size from 50 micron (typical for conventional processing methods) to 100 nm (achievable through high-energy ball milling). Though you'd also need to customize the chemistry to stabilize the grain size during the necessary thermal processing, I believe zirconium works well with iron.

- Q: I want to know if Diamond is stronger than Steel.

- Diamond is harder than steel, as diamond can scratch steel, but steel can't scratch diamond. However, I think steel is more structurally stable than diamond. Besides, how can you afford diamond girders, not even mentioning the impossibility of making a diamond that large.

- Q: full discription about hydrolics used in steel melting shop with hyd valve is use in thair circit too ?

- The correct spelling is hydraulics. I haven't heard the term steel melting shop you probably means a foundry or a steel mill The most obvious example i can think of is hydraulic-operated fork lifts. Hydraulic cylinders are used to lift the forks and to tilt them upwards or downwards. The valves are coneccted to levers next to the steering wheel. Hydraulic pressure is supplied by a hydraulic pump driven by a propane or diesel engine. In some forklift designs the wheels are also not connected directly to the engine, but driven by hydraulic motors. There are also a large variety of machines used in steel mills and metalworking companies to cut and shape metal parts. for example, press brakes, plate cutting shears, stamping presses, hole punch machines, drawing presses, etc. These types all operate in much the same basic way. They use a very large cylinder or group of cylinders to apply many tons of force to different kinds of metal working tools.

- Q: How are steel coils stored and transported?

- Steel coils are typically stored and transported in a horizontal position, either on the ground or on specially designed racks. They are often secured with steel straps or bands to prevent movement or damage during transportation. When being transported, steel coils are typically loaded onto flatbed trucks or shipping containers using cranes or forklifts. The coils are then secured in place with additional straps or chains to ensure stability during transit.

- Q: What are the common applications of hot-rolled steel coils?

- Hot-rolled steel coils are commonly used in various applications such as construction, automotive manufacturing, pipe and tube manufacturing, shipbuilding, and general engineering purposes. They are particularly suitable for projects that require strong and durable materials, as well as those that involve shaping and forming processes.

- Q: How do steel coil manufacturers minimize waste and maximize efficiency?

- Steel coil manufacturers can minimize waste and maximize efficiency through a combination of advanced technology, process optimization, and waste management practices. One way to achieve this is by using advanced automation and control systems in the production process. These systems can monitor and adjust various parameters such as temperature, pressure, and speed, ensuring that the manufacturing process operates at the optimal level. By closely monitoring and controlling these parameters, manufacturers can reduce the occurrence of defects and errors, which in turn minimizes waste. Another approach is to implement lean manufacturing principles. This involves eliminating any non-value-adding activities and streamlining the production process to reduce waste and increase efficiency. By carefully analyzing the entire production workflow, manufacturers can identify areas that can be improved, such as reducing setup times, eliminating bottlenecks, and optimizing material flow. This results in a more efficient and streamlined production process, minimizing waste and maximizing productivity. Furthermore, steel coil manufacturers can implement effective waste management practices. This includes proper handling and disposal of waste materials, as well as implementing recycling programs. By separating and recycling materials such as scrap metal, manufacturers can reduce the amount of waste generated and minimize the environmental impact of their operations. Additionally, manufacturers can explore partnerships with recycling companies to ensure that waste materials are properly managed and recycled. In summary, steel coil manufacturers can minimize waste and maximize efficiency by utilizing advanced technology, implementing lean manufacturing principles, and implementing effective waste management practices. By continuously striving for improvement and optimization in their processes, manufacturers can reduce waste, increase productivity, and ultimately achieve higher levels of efficiency.

Send your message to us

Hot dip Galvanized Steel Coil/GI/HDGI ASTM A653 0.13mm - 2.0mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords