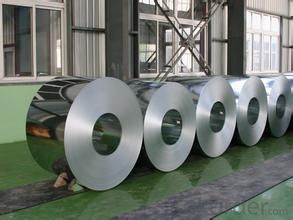

Hot-Dip Galvanized/ Aluzinc Steel in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

1.Mateials:SGCC,DX51D / DX52D /S250,280GD

2.Size:width:600-1250mm(900mm,1215mm,1250mm,1000mm the most common)

thickness:0.15-2.0mm

length:1000-6000mm,as your require

3.Zinc coating :60-180g( as required)

4.Coil id:508mm

5.Coil weight: 3-5MT(as required)

6. Surface:regular/mini/zero spangle, chromated, skin pass, dry etc.

Service:

1,on time delivery

2,high quality with competitive price

3,good service

4,long-term cooperation

5, rely on honors

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

- Q: What is the shear modulus of steel and silver? Please help! and state where you got it from...what site did you used? Thanks.

- Shear Modulus Of Steel

- Q: I am going to be working as a mechanic at my school and I just wanted to know if I should get the steel toe boots or regular. I heard that steel toe boots can be dangerous and uncomfortable. The mechanics recommended getting steel toe to be safe but i'm not sure.

- Get soft toe boots because if something falls on the steel toe boots the metal goes thru the boot and cuts you.

- Q: How do steel coils contribute to the renewable energy sector?

- Steel coils contribute to the renewable energy sector by playing a crucial role in the manufacturing of wind turbines and solar panels. These coils are used to produce the structural components of wind turbine towers and solar panel support structures. Additionally, steel coils are also utilized in the construction of transmission lines and grid infrastructure for renewable energy projects, ensuring efficient distribution of electricity generated from renewable sources.

- Q: Can steel coils be galvanized?

- Yes, steel coils can be galvanized. Galvanization is a process of applying a protective zinc coating to steel to prevent corrosion. Steel coils are often galvanized to increase their durability and resistance to rust.

- Q: full discription about hydrolics used in steel melting shop with hyd valve is use in thair circit too ?

- The correct spelling is hydraulics. I haven't heard the term steel melting shop you probably means a foundry or a steel mill The most obvious example i can think of is hydraulic-operated fork lifts. Hydraulic cylinders are used to lift the forks and to tilt them upwards or downwards. The valves are coneccted to levers next to the steering wheel. Hydraulic pressure is supplied by a hydraulic pump driven by a propane or diesel engine. In some forklift designs the wheels are also not connected directly to the engine, but driven by hydraulic motors. There are also a large variety of machines used in steel mills and metalworking companies to cut and shape metal parts. for example, press brakes, plate cutting shears, stamping presses, hole punch machines, drawing presses, etc. These types all operate in much the same basic way. They use a very large cylinder or group of cylinders to apply many tons of force to different kinds of metal working tools.

- Q: What are the different methods of coil recoiling for steel coils?

- Steel coils can undergo coil recoiling using various methods, each with its own advantages and applications. Some commonly used methods include: 1. Slitting and rewinding: This method entails cutting the wide steel coil into narrower strips, which are then rewound into smaller coils. Circular blade slitting machines are typically employed for steel cutting, while the rewinding process ensures tight and uniform winding of the narrower strips. Industries like automotive, construction, and packaging widely employ this method. 2. Rewinding with tension control: This method involves unwinding and rewinding the steel coil using tension control systems. These systems maintain consistent tension throughout the recoiling process, resulting in uniform winding quality. This method proves beneficial when handling delicate or sensitive materials that require gentle treatment. 3. Recoiling with edge trimming: In situations where steel coil edges are damaged, uneven, or flawed, edge trimming can be combined with the recoiling process. Edge trimming machines remove defective sections, ensuring coils with smooth and even edges. 4. Recoiling with surface treatment: Steel coils often undergo surface treatment processes like oiling, coating, or galvanizing to enhance corrosion resistance or improve surface properties. Recoiling can be performed alongside these treatments, guaranteeing proper application and uniform coverage across the entire coil surface. 5. Recoiling with tension leveling: Tension leveling is a process that eliminates coil shape defects, such as coil set or crossbow, by applying tension during recoiling. This method ensures a flat and even coil shape, which is advantageous for subsequent processing and manufacturing operations. 6. Recoiling with precision slitting: Precision slitting is a specialized method used to achieve extremely narrow strip widths or tight tolerances in the steel coil. It involves precise control of slitting knives and winding tension to ensure accurate and consistent strip dimensions. Industries requiring high precision, such as electronics or precision engineering, commonly employ this method. In summary, the choice of coil recoiling method depends on factors such as desired coil dimensions, material characteristics, surface requirements, and the specific industry or application. Manufacturers often combine multiple methods to meet the diverse needs of their customers.

- Q: How are steel coils measured for thickness?

- Steel coils are measured for thickness using a device called a micrometer or a thickness gauge. The micrometer is pressed against the coil's surface, and the measurement is displayed on its calibrated scale, providing an accurate reading of the steel coil's thickness.

- Q: How do steel coil manufacturers contribute to local economies?

- Steel coil manufacturers contribute to local economies in several ways. Firstly, they create employment opportunities by hiring a significant number of workers, thereby reducing unemployment rates and improving the standard of living in the community. These jobs often include a range of skill levels, from entry-level positions to highly specialized roles, providing a diverse range of employment options for locals. Additionally, steel coil manufacturers contribute to the local economy through their supply chain. They typically rely on local suppliers for raw materials, transportation services, and various support services, fostering business relationships and boosting the local economy. This leads to increased revenue for these suppliers and stimulates economic growth in the region. Moreover, the presence of steel coil manufacturers can attract other businesses to the area, such as logistics companies, distributors, and machine shops, which further enhances the local economy. This expansion of the industrial sector can result in a multiplier effect, generating additional job opportunities and attracting investment from outside the community. Lastly, steel coil manufacturers often engage in corporate social responsibility initiatives, such as supporting local charities, sponsoring community events, or investing in infrastructure development. These contributions not only have a positive social impact but also contribute to the overall economic development and well-being of the local community. In summary, steel coil manufacturers play a crucial role in local economies by creating jobs, stimulating the supply chain, attracting businesses, and investing in community development, all of which contribute to the growth and prosperity of the region.

- Q: How are steel coils used in the manufacturing of crash structures?

- Steel coils are used in the manufacturing of crash structures as they provide high tensile strength and durability, making them ideal for absorbing and distributing impact forces during a crash. These coils can be shaped and formed into various components such as beams, brackets, and panels, which are then integrated into the vehicle's frame or body structure to enhance its crashworthiness and protect occupants in the event of a collision.

- Q: What are the common transportation defects in steel coils?

- There are several common transportation defects that can occur in steel coils. One of the most common is coil damage caused by improper handling or securing during transportation. This can result in dents, scratches, or even tears in the steel. Another common defect is coil edge damage, which can occur if the coils are not properly protected or if they rub against each other during transit. This can lead to deformation or even breakage of the coil edges. Additionally, coil shifting is another common defect, which happens when the coils are not properly secured or braced, causing them to move and shift during transportation. This can result in misalignment or damage to the coils. Finally, coil corrosion is a common defect that can occur if the coils are exposed to moisture or other corrosive elements during transportation. This can lead to rust and deterioration of the steel. Overall, proper handling, securing, and protection measures are crucial in order to prevent these common transportation defects in steel coils.

Send your message to us

Hot-Dip Galvanized/ Aluzinc Steel in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords