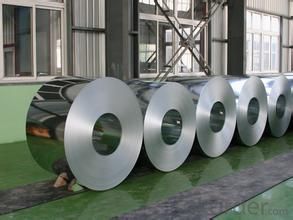

HOT-DIP GALVANIZED/ ALUZINC STEEL in China-SGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

THICKNESS:0.18mm-1.5mm

WIDTH:900mm-1250mm

COATING MASS:AZ30-AZ150

SPANGLE:Minimized Spangle,Zero Spangle

SURFACE TREATMENT:N0on or Chromated,Non or Oiled,Non or Anti Finger Print

COIL INNER DIAMETER:508mm/610mm

COIL WEIGHT:3mt-7m

Applications:

Galvalume Coil widely used for roofing products, It is also the ideal base material for Prepainted Steel Coil.

1. roofing

2. gutters

3. unexposed automotive parts

4. appliances

5. furniture

6. outdoor cabinetry

Images:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications.

Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

- Q: what is the differance between ceramic and stainless steel headers and 4-2-1 and 4-1 and which are better for racing and should i get ceramic or stainless steel headers???? for a 98 civic

- 4 into 2 into 1 is the style that the pipe finally necks down to one pipe. 4 into 1 is more restrictive but you wont really notice. Ceramic costs alot more but is better at keeping the high temps safe and wont warp or discolor, rust like other pipes, they are for more performance oriented vehicles. Stainless will do the job though for the average tuner.

- Q: How are steel coils used in the production of electrical connectors?

- Steel coils are used in the production of electrical connectors as they provide a strong and durable core component. The coils are wound into the desired shape and size, and then further processed to create the necessary conductive pathways for electrical current. This ensures stability, strength, and efficient conductivity in the connectors, making them suitable for various electrical applications.

- Q: How are steel coils used in the production of electrical motors?

- Steel coils are used in the production of electrical motors as the core component of the motor's electromagnet. The coils are wound around an iron core to create a magnetic field when electricity flows through them. This magnetic field interacts with other components in the motor to generate mechanical power, allowing the motor to function efficiently.

- Q: What are the common coil grades available for steel coils?

- The common coil grades available for steel coils are typically classified into three main categories: low carbon steel, medium carbon steel, and high carbon steel.

- Q: What are the different types of welding used for steel coils?

- Steel coil fabrication involves the utilization of various welding techniques, each catered to specific requirements and applications. Here, we present some commonly employed welding methods for steel coil fabrication: 1. Stick welding, also known as Shielded Metal Arc Welding (SMAW), utilizes a flux-coated electrode and an electric current to generate an arc between the electrode and the base material. SMAW is a versatile and extensively used technique suitable for a range of steel coil applications. 2. Gas Metal Arc Welding (GMAW), also referred to as MIG (Metal Inert Gas) welding, employs a continuous wire electrode and a shielding gas to safeguard the weld pool against atmospheric contamination. GMAW is renowned for its high welding speed and ease of automation, making it a favored choice for steel coil manufacturing. 3. Flux-Cored Arc Welding (FCAW) shares similarities with GMAW, but employs a tubular electrode with flux inside. The flux serves as both the shielding gas and added alloying elements, resulting in enhanced efficiency and weld quality. FCAW is often employed for high-speed welding applications in steel coil fabrication. 4. Gas Tungsten Arc Welding (GTAW), also known as TIG (Tungsten Inert Gas) welding, employs a non-consumable tungsten electrode and an inert gas, typically argon, to protect the weld area. GTAW delivers high-quality, precise welds with exceptional control over heat input, rendering it suitable for thin steel coil materials and critical welding scenarios. 5. Submerged Arc Welding (SAW) involves the use of a continuously fed wire electrode and a granular flux that covers the weld area. The arc is submerged beneath the flux, providing excellent protection and minimizing the need for post-weld cleaning. SAW is commonly employed for welding thick steel coils due to its high deposition rates and deep penetration capabilities. These examples highlight the diverse range of welding techniques employed in steel coil fabrication. The selection of the appropriate welding method depends on factors such as the specific steel grade, thickness, desired weld quality, production speed, and cost considerations. It is crucial to choose the suitable welding technique to ensure the longevity and performance of steel coils across different applications.

- Q: steel bollard poles?

- Steel Bollards are usually a security post to prevent 'ram raiding' of the fronts of stores and shops, most electrical/ photographic shops have them installed at the front, this helps to protect the shop frontage should a ram-raider, using a car, van or truck as a means to gain unauthorised access to a store after closing hours: .

- Q: What are the different methods of corrosion protection for steel coils?

- Steel coils can be protected from corrosion using several different methods, each with its own advantages and disadvantages. One commonly used method is to apply a protective coating to the steel coils. This can be done through various techniques like hot-dip galvanizing, electroplating, or painting. Coatings act as a barrier between the steel surface and the corrosive environment, preventing direct contact and reducing the risk of corrosion. Another option is the use of VCI materials, which release chemicals that inhibit corrosion when they come into contact with the steel surface. These materials can be applied as coatings, films, or papers, and are particularly useful for long-term storage or shipping of steel coils. Cathodic protection is a method that involves the use of sacrificial anodes or impressed currents. Sacrificial anodes, made of zinc or aluminum, are connected to the steel surface and corrode instead of the steel, sacrificing themselves to protect the coils. Impressed current systems use a direct electrical current to prevent corrosion on the steel surface. Proper wrapping and packaging can also provide corrosion protection for steel coils. This includes using moisture barrier films, desiccants, or absorbent materials to reduce moisture content. Adequate ventilation and avoiding contact with other corrosive substances are also important. Controlling the environment in which the steel coils are stored or used is crucial for corrosion protection. This involves maintaining proper humidity levels, controlling temperature, and managing air quality. By minimizing exposure to corrosive elements like moisture, salts, or chemicals, the risk of corrosion can be significantly reduced. It's worth noting that the choice of corrosion protection method depends on factors such as the specific application, budget constraints, and desired lifespan of the steel coils. A combination of these methods may also be used to enhance corrosion protection.

- Q: where can i get a thick sheet of steel ? and is steel bullet proff for example if you shoot a bullet on steel will that bullet bounce right off the steel ?

- Try the business-to-business yellow pages in your area. A local hardware store can also tell you who to contact. Or search steel plate or sheet metal on the internet to find a local supplier. No, sheet steel is not bullet proof, unless you get heavy plate. Depending on how thick it is, the plate will deform if hit by a high velocity bullet, but usually not enough to matter. Bullets have velocities from about 500 ft/sec up to roughly 3000 ft/sec, depending on the type of weapon used. I wouldn't try to use anything thinner than 3/4 inch. You'll have to experiment and see what it will actually stop. I can't guarantee it'll stop a high-velocity rifle slug. Try it and see.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or sunken designs on a material, and it can be applied to steel coils to add texture or decorative patterns.

- Q: like the steel industry and the effects it had on industrial growth, 10 points!

- The single most important important advance in steel production was learning to accurately control carbon content. This was done through the Bessemer Process in which air was blown through molten iron to burn out impurities and excess carbon. Low carbon iron (wrought iron) could be easily worked into shapes. Medium carbon iron could be cast into useful and durable shapes. High carbon steel could be used for structural uses (beams and girders). Adding alloys such as nickel and silicon could produce very tough steels and steels resistant to rust. Adding vanadium to steel engine parts allowed Ford to produce finely machined engines in huge numbers with existing machinery.

Send your message to us

HOT-DIP GALVANIZED/ ALUZINC STEEL in China-SGCC

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 5000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords