Hot-Dip Aluzinc Steel Coil Used for Industry with Our High Service and Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-Dip Aluzinc Steel Coil Used for Industry

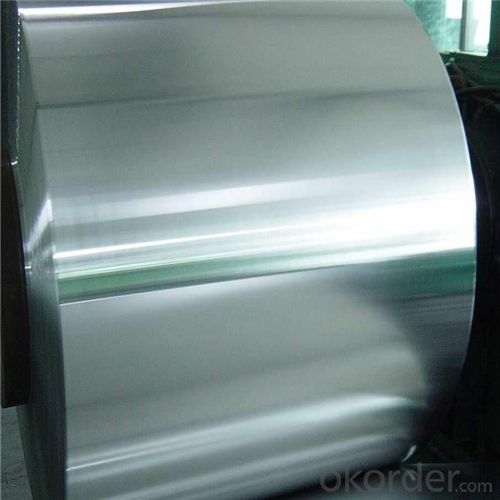

1.Structure of Hot-Dip Aluzinc Steel Coil Description

Hot-dip aluzinc steel sheet is substrated on cold rolled steel in various strength and specification. Coating composition is 55% aluminmum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent and heat resistance performance.

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils.

2.Main Features of the Hot-Dip Aluzinc Steel Coil

•High Purity

•Easy control and operation

•High strength

•Fast melting

•Competitive price

•Best Service

3. Hot-Dip Aluzinc Steel Coil Images

4. Hot-Dip Aluzinc Steel Coil Specification

Hot-Dip Aluzinc Steel Coil | |

Thicknenss | 0.16mm-3.5mm |

Width | 1250mm max |

Coating mass | 30-185g/㎡ |

Spangle | Regular/Minimized/Zero Spangle |

Coil inner diameter | 508-610mm |

Surface treatment | Chromated/non chromated, Oiled/non oiled, Anti finger print |

5.FAQ of Hot-Dip Aluzinc Steel Coil

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. .

②How to guarantee the quality of the products?

We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

- Q: which one(glass or steel)has more power and velocity? im planning on using my slingshot for hunting.

- Steel has more mass.

- Q: How are steel coils used in the production of infrastructure materials?

- Steel coils are commonly used in the production of infrastructure materials due to their strength and versatility. These coils are often transformed into various forms such as beams, plates, or pipes, which are then used in the construction of bridges, buildings, roads, and other vital infrastructure. The malleability and durability of steel make it an ideal material for withstanding heavy loads and harsh environmental conditions, ensuring the longevity and stability of the infrastructure.

- Q: How are steel coils handled during transportation to prevent damage?

- Steel coils are typically handled during transportation by using specialized equipment such as cranes or forklifts with padded forks. They are secured with steel bands or other restraints to prevent movement and damage. Additionally, they are usually loaded onto flatbed trucks or shipping containers with proper cushioning and support to minimize the risk of impact or deformation during transit.

- Q: How are steel coils used in the production of transportation equipment?

- Steel coils are used in the production of transportation equipment, such as automobiles, ships, and trains, to create various structural components. These coils are typically shaped and formed into parts like chassis, frames, bodies, and panels, providing strength, durability, and stability to the vehicles. Additionally, steel coils can be used in the manufacturing of wheels, axles, and suspension systems, ensuring reliable performance and safety in transportation equipment.

- Q: How are steel coils used in the production of automotive parts?

- Steel coils are used in the production of automotive parts as they are processed and shaped into various components such as body panels, chassis, and structural parts. These coils are typically unrolled, cut, and formed into the desired shape using specialized machinery. The flexibility, strength, and durability of steel make it an ideal material for manufacturing automotive parts, ensuring safety and reliability in the finished products.

- Q: How are steel coils loaded and unloaded from ships?

- Steel coils are typically loaded and unloaded from ships using cranes or heavy machinery. The coils are lifted onto the ship using hooks or clamps, and secured in place to prevent movement during transportation. Once the ship reaches its destination, the coils are then carefully lifted off the ship and transferred to trucks or other modes of transportation for further distribution.

- Q: Would the Ruger Sr22 pistol or the SW MP 15-22 be any good for the steel challenge?

- Diamond stressful situations the prevalent view of primitive societies as for this reason of a great number of exceptional causes quite. in case you study the e book he thinks that they are easily even smarter than us provided that that when he become once residing with the hot Guinea people he felt that he become once the single which become once boring because that he could no longer do wise duties similar to following a course and different stuff that they do of their daily time. also he thinks they're smarter because that we watch such plenty television, mutually they're actively residing existence. maximum of this counsel you'll come across on information superhighway website 20 -21. i variety of vaguely responded this question reason absolutely i have no theory what pejorative attitude..... i even regarded it up on-line for you and doesnt quite make sense too much.....

- Q: What are the different methods of blanking steel coils?

- There are several methods used for blanking steel coils, which are: 1. Shearing: This method involves cutting the steel coil into the desired size and shape using a shear or a set of shears. Shearing is a common method used for blanking steel coils as it is a fast and cost-effective process. It is suitable for cutting thin to medium-thickness steel coils. 2. Laser cutting: Laser cutting is a precise and efficient method that uses a high-powered laser beam to cut through the steel coil. It is suitable for cutting complex shapes and thick steel coils. Laser cutting provides clean and accurate cuts, making it a preferred method for high-quality blanking. 3. Waterjet cutting: Waterjet cutting uses a high-pressure stream of water mixed with an abrasive material to cut through the steel coil. This method is versatile and can cut through various materials, including steel, without generating heat. Waterjet cutting is suitable for cutting thick steel coils and is often used for intricate shapes and designs. 4. Stamping: Stamping is a method that involves pressing a die into the steel coil to cut out the desired shape. This process is commonly used for high-volume production as it can rapidly cut multiple pieces at once. Stamping is suitable for cutting simple shapes and is often combined with other processes like shearing or laser cutting for more complex shapes. 5. Plasma cutting: Plasma cutting uses a high-velocity jet of ionized gas to cut through the steel coil. It is suitable for cutting thick steel coils and can handle a wide range of materials. Plasma cutting is known for its speed and versatility, making it a popular method for blanking steel coils. These methods of blanking steel coils provide different benefits depending on the requirements of the project, such as speed, precision, complexity of shapes, and material thickness. The choice of method depends on factors like cost, production volume, desired quality, and turnaround time.

- Q: Hey guys do you know anything about Steel Arch Building and how this structure really looks like?

- i think a moment frame steel building with a parabolic arch from two corners with the top middle capstone looks pretty nice on four sides. on a plane view, the capstone forms a cross on roof top with a rectangular elevator shaft at middle and with several floors act as weight on the capstone. the four corners roof top floors have to have heavy columns reaching down to the foundation. then u draw a inverted V from the root of the arch to the capstone and filled the area between the arch and inverted V with trussed web members. this trussed arch can act as a wind bracing for the moment frame building. u have to investigate the proper angles for the trussed web members. if u set a vertical web member from the arch to the inverted V, that is at the largest gap and then build the truss web member from there. i would not only use one facade but double facade to increase the capacity of the building to resist vertical and lateral loads. however, the arch needs a tie beam to make sure the roots of the arch won't spread apart under compressive load and the load must be contain inside the arch. no one has build one like that yet.

- Q: Can steel coils be used in the production of furniture?

- Furniture production can incorporate steel coils, which offer strength, durability, and stability. This raw material is commonly utilized in manufacturing different types of furniture like chairs, tables, and bed frames. Steel coils enable heavy-duty usage by providing the necessary resilience. Furthermore, their adaptability allows for various designs and sizes, granting versatility in furniture production. Transforming the coils into components such as frames or support structures establishes a solid foundation. Additionally, the use of steel coils in furniture production enhances aesthetics as they can be finished in diverse colors and coatings to match the desired style. Overall, steel coils are a prevalent and pragmatic choice for furniture manufacturers due to their strength, durability, and design potential.

Send your message to us

Hot-Dip Aluzinc Steel Coil Used for Industry with Our High Service and Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 9000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords