Hot-dip Aluzinc Steel ASTM 615 SPCCH SPCC JIS3302

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 65665 m.t.

- Supply Capability:

- 2323 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame, 4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

2.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

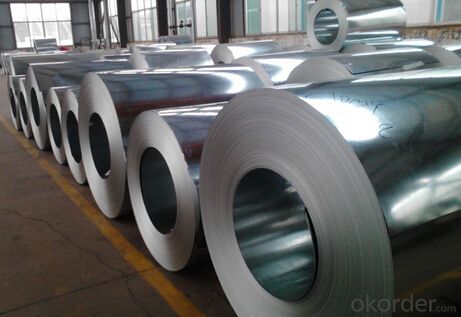

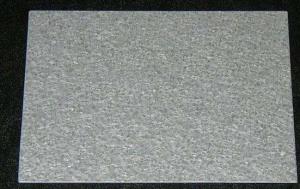

3.Hot-dip Aluzinc Steel Images

4.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION

HOT-DIP ALUZINC STEEL COILS | |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S250GD+AZ S280GD+AZ S550GD+AZ | SGLC440 SGLC490 SGLC570 |

5.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1.What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2.What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

3.Could you let me approach about your company in Dubai?

Located at Jebel Ali Free Zone in Dubai, CNBM Dubai Logistics Complex is adjacent to -Jebel Ali sea port-the largest port in UAE and Al Maktoum Airport-the largest airport in the world, which covers an area of 50,000 square meters, including an fully enclosed warehouse by 10,000 square meters, an open yard by 25000 square meters, and 13 standard unloading platform. CNBM Dubai Logistics Complex formally put into operation on August 1, 2013. Dubai Logistics Complex will commit itself to build the most professional and most influential building materials distribution center of China’s building materials industry in the UAE and throughout the Middle East and Africa.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets are highly weather-resistant due to their inherent strength and durability. They can withstand various weather conditions such as rain, snow, extreme temperatures, and UV exposure without deteriorating or losing their integrity. Additionally, steel sheets are resistant to corrosion, which further enhances their longevity and ability to withstand harsh weather conditions.

- Q: What is the process of manufacturing steel sheets?

- The process of manufacturing steel sheets involves several steps. First, iron ore is extracted from the ground and processed to remove impurities. This iron ore is then smelted in a blast furnace, along with coke and limestone, to produce molten iron. The molten iron is further refined in a basic oxygen furnace or an electric arc furnace to remove any remaining impurities and adjust the desired composition. Once the iron has been refined, it is converted into steel by adding alloying elements such as carbon, manganese, and other elements as required. The molten steel is then cast into large slabs or ingots. These slabs are reheated and passed through rolling mills to reduce their thickness and shape them into long, flat sheets. The sheets are then cooled, coated or treated as necessary, and cut into desired sizes before being packaged and shipped for various applications.

- Q: What are the different types of steel sheet finishes for decorative purposes?

- For decorative purposes, one can find several varieties of steel sheet finishes that are commonly utilized. These finishes are applied to the steel sheet's surface with the intention of enhancing its appearance and achieving a desired aesthetic effect. Some of the most favored finishes for decorative purposes are as follows: 1. Brushed Finish: Achieved by brushing the steel sheet's surface with a fine abrasive material, usually in a straight line pattern, this finish imparts a smooth and satin-like appearance. It is widely used in architectural and interior design applications. 2. Mirror Finish: Also known as a polished finish, this type creates a highly reflective surface that resembles a mirror. The steel sheet is mechanically polished to achieve this finish, and it is commonly seen in decorative applications such as furniture, lighting fixtures, and signage. 3. Patterned Finish: This finish involves embossing or etching a pattern onto the steel sheet's surface. It can be achieved through various techniques like stamping, laser engraving, or chemical etching. Patterned finishes provide a decorative and textured appearance and are often used in applications like elevator panels, wall cladding, and decorative screens. 4. Colored Finish: To add vibrancy and enhance visual appeal, steel sheets can be coated with a colored finish. Processes such as powder coating are employed, where a dry powder is applied to the steel sheet and then cured to create a durable, colored finish. Colored finishes are commonly used in architectural applications like building facades and signage. 5. Antique Finish: This particular finish is designed to give the steel sheet an aged or weathered look, resembling antique metal. Various techniques such as chemical treatments, patinas, or distressing can be employed to achieve this appearance. Antique finishes are often utilized in decorative applications to create a rustic or vintage aesthetic. These are just a few examples of the diverse range of steel sheet finishes available for decorative purposes. Each finish provides a distinct appearance and can be customized to suit specific design preferences. The choice of finish relies on factors such as the desired look, application, and required level of durability for the project.

- Q: Can the steel sheets be easily folded or creased?

- No, steel sheets cannot be easily folded or creased due to their strong and rigid nature.

- Q: Do steel sheets require any surface treatment before installation?

- Surface treatment is typically necessary for steel sheets before they are installed. This is because it improves the steel's durability and appearance, and also protects it from corrosion. The most common methods of surface treatment for steel sheets are galvanization, painting, and powder coating. Galvanization involves adding a zinc coating to the steel, which helps prevent rust and corrosion. On the other hand, painting and powder coating involve applying a protective layer of paint or powder to the steel surface. These surface treatments not only make the steel look better but also make it more resistant to environmental factors like moisture, chemicals, and UV radiation. Therefore, it is advisable to apply the appropriate surface treatment to steel sheets before installation in order to ensure their long-lasting performance.

- Q: Can steel sheets be used for manufacturing furniture?

- Yes, steel sheets can be used for manufacturing furniture. Steel is a strong and durable material that can be shaped and formed into various furniture designs. It offers a sleek and modern aesthetic and can be used for making chairs, tables, shelves, and other furniture pieces.

- Q: What's the difference between steel plate 20 and Q235 steel plate?

- In the normalizing state of No. 20 steel, the yield point is 245MPa, the elongation is >25%, the quenched and tempered state, the yield point is 280MPa, and the elongation is >22%. Widely used in the production of small, high load toughness requirements of parts, such as rod, heavy and general machinery in forging the sleeve, fixture and liner, general machinery and automobiles and tractors in small parts of carburizing, cyaniding.

- Q: What is the difference between a steel sheet and a steel plate?

- The main difference between a steel sheet and a steel plate is their thickness. Steel sheets are generally thinner, ranging from 0.4mm to 6mm, while steel plates are thicker, typically starting from 6mm and can go up to several inches in thickness. Additionally, steel plates are often used for structural purposes or heavy-duty applications, while steel sheets are commonly utilized for lighter applications like roofing, cladding, or decorative purposes.

- Q: Can steel sheets be used for staircase railings?

- Indeed, staircase railings can be fashioned from steel sheets. Steel, renowned for its durability and strength, is frequently employed in construction and engineering endeavors. By manipulating steel sheets, one can fashion diverse forms and patterns, resulting in chic and contemporary staircase railings. Such railings can be effortlessly tailored to complement various architectural styles and personal tastes. Furthermore, steel railings are celebrated for their enduring nature and minimal upkeep demands, rendering them a favored option for staircase installations.

- Q: How do steel sheets perform in extreme weather conditions?

- Steel sheets perform well in extreme weather conditions due to their high strength and durability. They are resistant to corrosion, fire, and can withstand intense winds, heavy rain, and extreme temperatures. Additionally, steel sheets have excellent structural stability, making them suitable for use in various applications, such as roofing, cladding, and construction, even in harsh weather environments.

Send your message to us

Hot-dip Aluzinc Steel ASTM 615 SPCCH SPCC JIS3302

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 65665 m.t.

- Supply Capability:

- 2323 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords