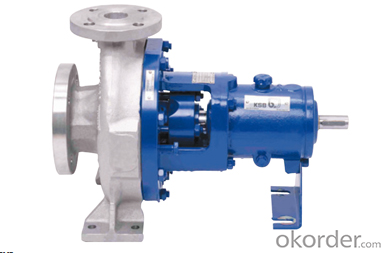

Horizontal, radially split volute casing pump CPKN

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Design |

Overview of technical data

| Type of impeller | Closed; Radial |

| Type of installation | Long- coupled |

| Maximum drive rating | 3. 200 kW |

| Impeller material (EN standard) | NORIDUR 1. 4593;JL 1040;1.4408 |

| Type of bearing | Rolling element bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 3. 500 1/min |

| Maximum flow rate | 4. 800 m³/h |

| Maximum discharge-side pressure | 25 bar |

| Casing material (EN standard) | NORIDUR 1. 4593;1.4408;JS 1025;GP240GH+N |

| No. of impeller entries | Single entry |

| Casing material | Cast stainless steel; Ni-Resist;Cast duplex steel;Cast steel;Nodular cast iron |

| Minimum flow rate | 1 m³/h |

| Suction characteristics | Non- priming |

| Drive voltage | Low voltage |

| eClass assignment | 36410000; 36410100;36410101 |

| Pull-out design | Yes |

| Pump set location | Dry installed |

| Heatable | Yes |

| Max. permissible fluid temperature | 400 ****** |

| Main applications | Energy; Industry and process engineering |

| Type of installation | 00 |

| Type of casing | Volute casing |

| Type of connection | Flange |

| Type of lubrication | Oil lubrication |

| Type of drive | Electric motor |

| Installation position | Horizontal |

| Shaft material (EN standard) | 1. 4462;1.5680;C 45+N;1.7709 |

| Type of coupling | Direct |

| Shaft seal type | Mechanical seal |

| Maximum head | 275, 00 m |

| Maximum rated pressure (discharge) | PN 25 |

| Minimum head | 2, 00 m |

| Standard | ISO 5199; ISO 2858;EN 22858 |

| Nozzle position | End suction |

| Casing partition | Radially split |

- Q: You'd better point out the details.... There are 2 best ways of experience and formulaCan you say a simple point, such as multi-stage pump, when the pump is higher than the motor, 30 wire is the next mouth how to do?

- Looking forAlignment means the position of the center of rotation of the pump and motor so that they are in the same line.At least three times after the initial installation or after installation:

- Q: What is the pump lift voltage? And how to suppress the pumping voltage rise?

- The elevator is mainly used by the power grid through the rectifier, filter, inverter and other transmission to the motor. The motor in high speed when the brake suddenly, but the rotor of the motor with the load (production machinery) mechanical inertia, could not stop quickly, resulting in the back EMF (EU voltage) motor is in the state of power, the reverse voltage and torque original electric state torque instead, and the motor with brake strong torque, forcing the rotor to stop fast but usually AC-DC-AC converter is the main power AC/DC rectifier circuit is irreversible and therefore cannot go back to the grid, energy will be accumulated in the filter capacitor, produce pump voltage, this phenomenon of pump voltage converter has great destructive power.

- Q: How much water does the water ring vacuum pump run for an hour? If there is no steam separator, does the water vaporize?

- For example: water storage is relatively small, it needs to reduce the temperature of the heat exchanger. If the tank is relatively large, it does not need cooling water circulation pump again when the temperature is very low, there is no need to heat exchanger. So you need to ask how much water this is not OK.In a soda separator problem:

- Q: What should I pay attention to when buying a pump?

- Two, the first choice of large and medium-sized professional manufacturers, and through the quality identification of relevant departments, the market credibility of the better models, but also to the professional quality inspection institutions consultation.Three, check the motor grounding device for electric pump, water pump and motor axis, the motor should be in a proper position is provided with a grounding screw, and the grounding screw are arranged near the ground; grounding device of small submersible pump should be reliable and grounding wire, grounding wire cables should have the obvious grounding mark the flag should be in use; the motor is not easy to be worn during the period. This is one of the important safety indexes of electric pumps.

- Q: Pump unloading in hydraulic transmission,

- Can be used for short-term shutdown, pump non-stopNo unloading, usually through the overflow valve back to the tank, high pressure, power, at this time insurable pressure, and so on

- Q: What is double hydraulic pump?

- [double hydraulic pump] the same drive shaft drives the rotation of two pumps, which are connected together and driven by an electric motor. The suction port of the pump is common, and the oil pressure port is separated from each other. Pump output of two shares of flow can be used alone, can also be used in parallel. This pump, a pump can play the function of two pumps. For example, there are two pumps on the loader, a pump acting as the work, a pump acting as the steering, and the double linked pump can replace the functions of the two pumps. It works by coupling the two pumps at the same time.

- Q: I live on the 8 floor. Often there is no water. Life is very inconvenient. What kind of pump do I have to install? What should I pay attention to when I buy it? What's the pump for that brand? Should it be installed in that position?

- (8) check the suitability of the foundation and whether the size of the foundation corresponds to the size of the pump.(9) find the position of positive pump and motor, pump set and anchor bolt and the inlet and outlet flanges, to ensure that the flange torque of the pump conforms to the standard. Check the inlet and outlet piping before alignment. Make sure the weight of the inlet and outlet pipe does not exert force or torque on the pump. When looking for, should also pay attention to eliminate the pump rotor movement, so as to avoid the end gap error. If checked after the pump is working, it should be carried out under cold condition. It is important to draw attention to the fact that the pump set of the complete set of factory is only rough looking (checked with a ruler) when it is shipped. It may cause displacement when it is transported.

- Q: Is the centrifugal pump large or small?

- Centrifugal pump, the smaller the better the cavitation.1, centrifugal pump cavitation less, anti cavitation performance is better, the pump cavitation is called the necessary cavitation margin or pump inlet dynamic pressure drop, the smaller the better. Generally speaking, the pump cavitation is the need for cavitation, the pump inlet pipe said effective cavitation margin, that is, the device cavitation margin. For a given pump, at a given speed and flow rate required NPSH is called pump necessary NPSH, also called NPSH, is required to achieve the performance parameters of the pump cavitation, the internal flow and the centrifugal pump is composed of pump head itself, its physical meaning is that liquid drop in pump inlet pressure part degree, is to guarantee the pump cavitation does not occur, with surplus energy exceeds the vaporization pressure head at the inlet of the pump unit weight of liquid. The cavitation must be independent of the device parameters. It is only related to the parameters of the inlet of the pump. These parameters are determined by the geometric parameters at a given speed and flow.

- Q: What flowmeter is installed after the pneumatic diaphragm pump?

- Compressed air source, the general pneumatic diaphragm pump starting gas source for 0.1~0.2mpa,The maximum working pressure is 0.7~0.8mpa, so in this pressure range, you can use the air filter relief pressure valve gas pipe, adjusting for air pressure, when the pressure is bigger, diaphragm movement faster, so the greater the flow, and vice versa

- Q: What's the submersible pump?What is a submersible pump, and what about it?

- Deep well submersible pump is a fountain, drinking water transportation, irrigation, hot springs, high-rise transport facilities, etc., deep well submersible pump excellent performance, so widely used in various fields.

Send your message to us

Horizontal, radially split volute casing pump CPKN

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 1 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches