High Yield Steel Deformed Bar of Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

High Yield Steel Deformed Bar of Building Material

Description of High Yield Steel Deformed Bar

1, Diameter: 5.5mm-10mm High Yield Steel Deformed Bar

10m- 40mm High Yield Steel Deformed Bar

2, Length: 6m, 9m, 12m or customized

3, Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN

OEM technology - send detailed technical parameters for accurate quotation.

2, Produce Process: smelt iron - EAF smelt billet - ESR smelt billet -

hot rolled or forged to get the steel round bar and plate

3, Heat Treatment: annealing, normalizing, tempering, quenching

4, Surface Treatment: Black

5, Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Chemical Composition of High Yield Steel Deformed Bar

Grade | Technical data of the original chemical composition(%) | |||||

Reinforcing steel bar HRB335 | C | Mn | Si | S | P | B |

≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 335 | ≥490 | ≥16 | ||||

Reinforcing steel bar HRB400 | C | Mn | Si | S | P | B |

≤0.25 | ≤0.16 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

Physics Capability | ||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation(%) | ||||

≥ 400 | ≥ 570 | ≥ 14 | ||||

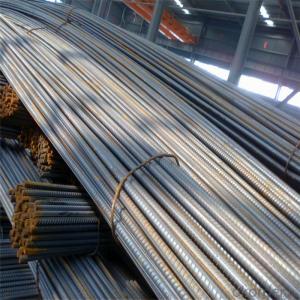

Products Show of High Yield Steel Deformed Bar

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and logistics solutions.

F A Q

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

- Q: What are the different applications of tool special steel?

- Tool special steel is a versatile material that finds applications in various industries due to its unique properties. Some of the different applications of tool special steel include: 1. Cutting Tools: Tool special steel is widely used in the manufacturing of cutting tools such as drills, saw blades, milling cutters, and lathe tools. Its high hardness, wear resistance, and toughness make it ideal for these applications, ensuring long tool life and excellent cutting performance. 2. Dies and Molds: Tool special steel is also extensively used in the production of dies and molds for metalworking and plastic injection molding processes. Its ability to withstand high temperatures, resist wear and deformation, and maintain dimensional stability make it suitable for these demanding applications. 3. Automotive Industry: Tool special steel is employed in the automotive industry for various components such as crankshafts, gears, camshafts, and engine valves. Its excellent strength, fatigue resistance, and heat resistance qualities contribute to the overall durability and performance of automotive parts. 4. Aerospace Industry: Tool special steel is utilized in the aerospace industry for applications such as turbine blades, aircraft engine components, landing gears, and structural parts. Its high strength, corrosion resistance, and ability to withstand extreme temperatures and pressure make it an ideal choice for these critical applications. 5. Construction and Mining: Tool special steel is used in the construction and mining sectors for equipment such as excavator buckets, rock drills, bulldozer blades, and drilling bits. Its high hardness, toughness, and resistance to abrasion enable these tools to withstand the harsh conditions encountered in these industries. 6. Tooling Industry: As the name suggests, tool special steel is extensively used in the tooling industry for the manufacture of various types of tools and equipment. Whether it is hand tools, power tools, or precision instruments, tool special steel is employed due to its exceptional strength, hardness, and resistance to wear and deformation. 7. Medical Industry: Tool special steel is also utilized in the medical field for the production of surgical instruments, orthopedic implants, and dental tools. Its biocompatibility, corrosion resistance, and ability to be sterilized make it suitable for these critical applications. These are just a few examples of the numerous applications of tool special steel. Its unique properties make it a valuable material in various industries where durability, strength, and precision are essential requirements.

- Q: How is special steel used in the production of aircraft landing gear?

- Due to its outstanding mechanical properties and durability, special steel is extensively utilized in the manufacturing of aircraft landing gear. The landing gear, a critical component responsible for supporting the weight of an aircraft during takeoff, landing, and ground operations, must endure tremendous forces, impact loads, and harsh environmental conditions. Special steel, including high-strength low-alloy (HSLA) steel or alloy steel, is carefully chosen for its remarkable strength-to-weight ratio, high resistance to fatigue, and excellent ability to resist corrosion. These characteristics are essential in ensuring that the landing gear can withstand the extreme forces and stresses encountered during aircraft operations. The utilization of special steel in the production of landing gear offers multiple advantages. Firstly, it enables the landing gear to be lighter in weight, contributing to an overall reduction in the aircraft's weight. This results in improved fuel efficiency and increased capacity for carrying cargo, which are crucial factors in enhancing the performance of modern aircraft and reducing operating costs. Secondly, the high fatigue resistance of special steel ensures that the landing gear can endure repeated loading cycles without experiencing significant degradation in performance. This is of utmost importance since the landing gear is subjected to substantial stress during each landing and takeoff. It must be capable of withstanding these forces over a long operational lifespan. Furthermore, the excellent corrosion resistance properties of special steel guarantee that the landing gear remains protected from environmental elements such as moisture, salt, and other corrosive substances. Corrosion can weaken the structure of the landing gear, compromising its integrity and safety. Therefore, the use of special steel helps to ensure the longevity and reliability of the landing gear, reducing the need for maintenance and associated costs. To summarize, special steel plays a vital role in the manufacturing of aircraft landing gear due to its exceptional strength, fatigue resistance, and corrosion resistance. Its incorporation allows for the production of lighter and more durable landing gear, resulting in improved aircraft performance, enhanced efficiency, and increased safety.

- Q: Can special steel be used for making springs?

- Yes, special steel can be used for making springs. Special steel, also known as alloy steel, offers enhanced mechanical properties such as high tensile strength, toughness, and corrosion resistance. These characteristics make it an ideal material for manufacturing springs that require durability and reliability in various applications. The specific type of special steel used for springs depends on the requirements of the application, such as the desired level of flexibility or resistance to fatigue. Overall, special steel provides excellent performance and longevity in spring manufacturing.

- Q: How does special steel perform in case hardening applications?

- In case hardening applications, the performance of special steel is outstanding. Case hardening, a heat treatment process, is used to increase the surface hardness of a material while maintaining its tough and ductile core. Special steel, also known as alloy steel, is specifically formulated to have enhanced properties like high strength, toughness, and wear resistance. When it comes to case hardening, special steel is the ideal choice due to its ability to form a hard outer layer while retaining its core properties. Typically, the process involves heating the steel to a specific temperature and then introducing a carbon-rich environment, such as through carburizing or carbonitriding. The carbon atoms diffuse into the steel's surface, creating a high-carbon layer called the case, which significantly increases hardness and wear resistance. Compared to other types of steel, special steel's high carbon content allows for deeper and more uniform case hardening. This results in improved durability, reduced friction, and enhanced resistance to wear, abrasion, and impact. Moreover, the tough core of special steel ensures that the material remains resistant to cracking or fracturing under high stress or impact loads. Furthermore, special steel offers excellent machinability, making it easy to process during case hardening applications. This makes it a preferred choice for various industries, including automotive, aerospace, tooling, and manufacturing, where components require both high surface hardness and structural integrity. Overall, special steel is highly regarded for its exceptional performance in case hardening applications. Its combination of high strength, toughness, wear resistance, and machinability makes it an excellent choice for producing durable and reliable components that can withstand demanding operating conditions.

- Q: What are the physical properties of special steel?

- Compared to regular steel, special steel possesses unique physical properties. These properties can vary depending on the specific composition and processing techniques employed. However, special steel typically exhibits high strength, hardness, and durability. Its design often aims to withstand extreme conditions, including high temperatures, pressure, and corrosive environments. Additionally, special steel may display exceptional wear resistance, making it suitable for applications involving heavy machinery or cutting tools. Moreover, it can possess superior electrical and thermal conductivity, along with favorable magnetic properties. In conclusion, the physical properties of special steel render it highly versatile and valuable across various industries, such as automotive, aerospace, construction, and energy.

- Q: How does special steel perform under extreme temperatures?

- Special steel has been specifically engineered to excel in extreme temperature conditions. It boasts outstanding strength, hardness, and heat resistance, making it an ideal choice for applications involving extreme heat or cold. When exposed to high temperatures, special steel maintains its structural integrity, avoiding significant deformation or loss of strength. It also retains its hardness and dimensional stability, ensuring that it can withstand extreme conditions without compromising its performance. One of the key properties of special steel is its exceptional resistance to thermal expansion and contraction. This is particularly important when faced with drastic temperature changes. By expanding and contracting uniformly, the steel minimizes the risk of cracking or other types of damage. Furthermore, special steel exhibits remarkable heat resistance, allowing it to preserve its mechanical properties even at elevated temperatures. It demonstrates high creep resistance, which means it can resist deformation under constant stress in high-temperature environments. This ensures that the steel can endure prolonged exposure to extreme heat without experiencing failure or degradation. Not only does special steel perform exceptionally well at high temperatures, but it also excels in extremely low temperatures. It maintains its toughness and ductility, with minimal risk of embrittlement or cracking. This makes it highly suitable for cryogenic environments in industries such as aerospace or medicine. In conclusion, special steel has been specifically designed to outperform in extreme temperature conditions, offering impressive strength, hardness, and heat resistance. Its ability to maintain structural integrity, resist thermal expansion and contraction, and withstand high or low temperatures make it a dependable choice for various demanding applications.

- Q: How is special steel used in the aerospace sector?

- Special steel is used in the aerospace sector for various applications such as manufacturing engine components, landing gear, and structural parts. Its high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme temperatures make it ideal for enhancing the performance, durability, and safety of aircraft.

- Q: How do alloying elements affect the properties of special steel?

- Alloying elements play a crucial role in determining the properties of special steel. By adding specific elements to the steel composition, various desirable characteristics can be achieved. Firstly, alloying elements can improve the strength and hardness of the steel. For example, elements like chromium, nickel, and molybdenum enhance the steel's resistance to deformation and improve its overall toughness. This is particularly important in applications where the steel needs to withstand high temperatures, pressure, or mechanical stress. Moreover, alloying elements can enhance the corrosion resistance of special steel. Elements such as chromium, nickel, and copper create a protective oxide layer on the surface of the steel, which prevents it from rusting or corroding. This is particularly important in industries such as marine, oil and gas, and chemical processing, where exposure to corrosive environments is common. Additionally, alloying elements can influence the steel's ability to be welded, machined, or heat treated. For instance, elements like manganese and silicon improve the weldability of steel, making it easier to join different components together. On the other hand, elements like vanadium and tungsten increase the steel's ability to retain its hardness even after being subjected to high temperatures, making it suitable for applications involving heat treatment. Furthermore, alloying elements can impact the steel's electrical and magnetic properties. Elements like nickel and cobalt can enhance the steel's magnetic properties, making it suitable for applications in electrical transformers or magnetic devices. Conversely, elements like aluminum and titanium can improve the steel's electrical conductivity, making it ideal for electrical wiring or conductive components. In summary, alloying elements have a significant impact on the properties of special steel. They can enhance its strength, hardness, corrosion resistance, weldability, heat treatability, electrical conductivity, and magnetic properties. By carefully selecting and controlling the alloying elements, manufacturers can tailor the steel's properties to meet the specific requirements of various industries and applications.

- Q: How does special steel contribute to the renewable energy storage?

- Special steel plays a crucial role in renewable energy storage by enabling the construction of durable and efficient energy storage systems. It is used in the manufacturing of batteries, fuel cells, and other components, providing strength, corrosion resistance, and thermal stability. The high-quality properties of special steel help enhance the performance and longevity of renewable energy storage technologies, ensuring their reliability and contributing to the overall sustainability and viability of the renewable energy sector.

- Q: What are the main properties of special steel?

- Special steel, also known as alloy steel, possesses several key properties that set it apart from regular steel. Firstly, it exhibits exceptional strength and hardness, making it highly resistant to wear, impact, and deformation. Additionally, special steel offers excellent corrosion resistance, ensuring durability and longevity in various environments. It also demonstrates superior heat resistance, allowing it to withstand high temperatures without losing its structural integrity. Lastly, special steel offers excellent machinability, enabling it to be easily shaped, fabricated, and processed into a wide range of components and structures.

Send your message to us

High Yield Steel Deformed Bar of Building Material

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords