High Quality Deformed Steel Bar For Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

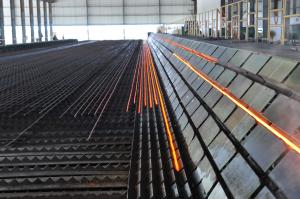

OKorder is offering High Quality Deformed Steel Bar For Construction at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to African, South American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

High Quality Deformed Steel Bar For Construction are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's High Quality Deformed Steel Bar For Construction are durable, strong, and wide variety of sizes.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: HRB335

Size: 6mm-25mm

Certificates: ISO, SGS, BV, CIQ

Length: 6m – 12m, as per customer request

Packaging: Export packing, nude packing, bundled

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | B | |||

HRB335 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | >0.0008 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%) | ||||||

≥335 | ≥490 | ≥16 | ||||||

Grade | Technical data of the original chemical composition (%) | |||||||

C | Mn | Si | S | P | V | |||

HRB400 | ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | ||

Physics capability | ||||||||

Yield Strength(N/cm2) | Tensile Strength(N/cm2) | Elongation (%) | ||||||

≥400 | ≥570 | ≥14 | ||||||

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: what is the difference between actual weight and theoretical weight?

A3: All the section steel has two weights: actual weight and theoretical weight. Actual weight is the weighing out when the product delivered from the mill. Theoretical weight is calculated by pieces. The invoice can be based on each of them as your request.

.

Images:

- Q: How are steel rebars protected during the concrete pouring process?

- To ensure the longevity and structural integrity of steel rebars during the concrete pouring process, several protective measures are implemented. Initially, prior to pouring the concrete, the rebars undergo meticulous cleaning to eliminate any rust, dirt, or contaminants that may compromise the bond between the rebar and the concrete. This is typically achieved by utilizing a wire brush or other mechanical methods. Once the rebars have been thoroughly cleaned, a common practice is to apply a protective layer or coating to them. An epoxy coating is frequently employed for this purpose. The coating acts as a barrier, preventing moisture and chemicals from reaching the steel and causing corrosion. Epoxy coatings are especially valuable in high-risk environments like marine structures or areas with a high chloride content. Another protective method involves the use of corrosion inhibitors. These inhibitors are added to the concrete mixture, which subsequently forms a protective layer around the rebars. By reducing the corrosive effects of chloride ions, oxygen, and other chemicals, the inhibitors work to prevent corrosion. Additionally, it is crucial to ensure adequate concrete cover over the rebars during the pouring process. Concrete cover refers to the thickness of the concrete layer between the surface and the rebar. Sufficient concrete cover safeguards the rebars against exposure to moisture, chemicals, and other environmental factors. To achieve the desired concrete cover, steel stirrups or spacers are positioned around the rebars to maintain a specific distance between the rebar and the formwork. This guarantees even distribution of the concrete around the rebars, providing them with the necessary protection. In conclusion, steel rebars are shielded during the concrete pouring process through various methods, including thorough cleaning, the application of protective coatings, the use of corrosion inhibitors, and the maintenance of proper concrete cover. These measures effectively prevent corrosion and ensure the durability and strength of the reinforced concrete structure.

- Q: What is the difference between hot-rolled and cold-worked steel rebars?

- Hot-rolled steel rebars are made by heating the steel billets to high temperatures and then rolling them into the desired shape, resulting in a rougher surface texture. On the other hand, cold-worked steel rebars are produced at room temperature, undergoing processes like cold drawing or cold rolling, which improve the surface finish and dimensional accuracy. Cold-worked rebars are often used in applications where a smoother surface is required, such as in concrete reinforcement or in the manufacturing of precision components.

- Q: Can steel rebars be used in the construction of railway tracks?

- Yes, steel rebars can be used in the construction of railway tracks. They are commonly used as reinforcement in the concrete sleepers, which are an integral part of the railway track system. The rebars provide strength and durability to the sleepers, ensuring the stability and longevity of the tracks.

- Q: What is the role of steel rebars in preventing concrete spalling?

- The role of steel rebars in preventing concrete spalling is to provide reinforcement and strength to the concrete structure. When concrete is reinforced with steel rebars, it can better resist the forces that cause spalling such as expansion and contraction due to temperature changes, moisture penetration, and structural loads. The rebars help distribute stress and prevent cracking, which in turn reduces the likelihood of spalling occurring.

- Q: How do steel rebars affect the environmental sustainability of a structure?

- Steel rebars can have both positive and negative impacts on the environmental sustainability of a structure. On one hand, steel rebars are a sustainable choice as they are made from recycled materials. Steel is one of the most recycled materials in the world, which helps in reducing the demand for virgin resources and the associated environmental impacts of extraction and processing. Additionally, steel rebars are highly durable and have a long lifespan, which means that structures reinforced with steel rebars require less maintenance and replacement over time. This reduces the overall environmental impact associated with the construction and demolition of structures. On the other hand, the production of steel rebars has some negative environmental consequences. The manufacturing process involves high energy consumption, carbon emissions, and the release of pollutants into the atmosphere. The extraction and processing of iron ore, as well as the conversion of iron into steel, can contribute to deforestation, air and water pollution, and habitat destruction. However, the negative impacts of steel rebars can be mitigated through sustainable manufacturing practices. For example, using energy-efficient technologies, utilizing renewable energy sources, and implementing strict emissions controls can help reduce the environmental footprint of steel production. Moreover, the environmental sustainability of a structure also depends on the overall design and construction practices. By adopting sustainable design principles, such as optimizing the use of materials, minimizing waste, and incorporating energy-efficient features, the negative impacts of steel rebars can be further reduced. In conclusion, while steel rebars have some negative environmental impacts in their production process, their use in construction offers several sustainability benefits such as recycling, durability, and reduced maintenance needs. By adopting sustainable manufacturing practices and integrating them into environmentally conscious design and construction practices, the overall environmental sustainability of structures can be greatly enhanced.

- Q: Can steel rebars be used in parking structures?

- Yes, steel rebars can be used in parking structures. Steel rebars are commonly used as reinforcement in concrete structures, including parking structures, to provide added strength and durability. They help to increase the load-bearing capacity and resistance to cracking or bending, making them suitable for use in parking structures where heavy vehicles and constant traffic are expected.

- Q: What is the process of anchoring steel rebars in masonry walls?

- To ensure a secure and reliable connection between the steel reinforcement and the masonry structure, several steps are involved in anchoring steel rebars in masonry walls. Firstly, a detailed design and plan for the reinforcement layout in the masonry wall must be established. This involves determining the spacing, size, and placement of the rebars based on structural requirements. Next, the masonry wall needs to be prepared by cleaning the surface and removing any loose debris or obstructions. This creates a clean and stable base for the rebars. Then, holes are drilled into the masonry wall at predetermined locations according to the reinforcement design. These holes are slightly larger than the diameter of the rebars to allow for easy insertion. After drilling, the holes are cleaned to remove any dust or debris. A bonding agent, such as epoxy or cementitious grout, is then applied to the holes. This enhances the bond between the rebars and the masonry wall. The steel rebars are then inserted into the prepared holes, ensuring alignment according to the reinforcement design. They are pushed into the holes until they reach the desired depth, fully embedding them in the bonding agent. Once the rebars are in place, the bonding agent needs time to cure and harden. The curing time varies depending on the type of bonding agent used and the environmental conditions. It is crucial to follow the recommended curing time to ensure secure anchoring. After the curing process is complete, a thorough inspection is conducted to ensure the rebars are properly anchored and meet the required specifications. This involves checking for proper alignment, depth, and overall stability. By following these steps, the process of anchoring steel rebars in masonry walls provides structural reinforcement and strength to the overall masonry structure. This enhances durability and resistance to various forces and loads.

- Q: What is the difference between the actual weight and the actual weight of the steel thread?

- As for the calculation of it, big steel mills are GB, generally within 70-80 thousandths of the difference, a little less than 30-40 kilograms of good, bad 80-90 kilograms. Science is the brand superscript weight, the actual weight is weighing several pounds, no difference multiplied by the coefficient, the factory difference is not the same, for example, Xilin Iron and steel will be multiplied by (1-0.06 or 0.07)

- Q: How are steel rebars classified based on their yield strength?

- Steel rebars are classified based on their yield strength into different grades or classes, such as Grade 40, Grade 60, and Grade 75. The yield strength represents the amount of stress a rebar can withstand before it starts to deform permanently. Higher yield strength rebars can bear greater loads and are therefore used in applications that require stronger reinforcement.

- Q: How do steel rebars affect the overall ductility of concrete structures?

- Steel rebars greatly enhance the overall ductility of concrete structures. By providing tensile strength, rebars prevent concrete from cracking and failing under tensile loads. This reinforcement allows the concrete to deform and absorb energy before reaching its ultimate failure point, ensuring the structure's ability to withstand seismic forces and other extreme loads.

Send your message to us

High Quality Deformed Steel Bar For Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords