Hot Rolled Deformed Steel Rebars for Constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Hot Rolled Deformed Steel Rebars for Constrution:

Standard | GB UK USA | HRB335 HRB400 HRB500 G460B, B500A, B500B,B500C GR40, GR60 | |

Diameter | 6mm,8mm,10mm,12mm,14mm,16mm,18mm,20mm, 22mm,25mm,28mm,32mm,36mm,40mm,50mm | ||

Length | 6M, 9M,12M or as required | ||

Price | Keep lower operating costs so as to offer competitive price for our clients | ||

Delivery Detail | within 45 days after received advanced payment or LC. | ||

Application | mainly used in construction industry to reinforce concrete structures and so on | ||

Invoicing | Actual or Theoretical Weight Basis as buyer’s request. | ||

Type | Hot rolled steel rebar | ||

Brand name | DRAGON | ||

Theoretical weight and section area of each diameter as below for your information:

Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m (kg) | Pcs/ton |

6 | 28.27 | 0.222 | 2.664 | 375.38 |

8 | 50.27 | 0.395 | 4.74 | 210.97 |

10 | 78.54 | 0.617 | 7.404 | 135.06 |

12 | 113.1 | 0.888 | 10.656 | 93.84 |

14 | 153.9 | 1.21 | 14.52 | 68.87 |

16 | 201.1 | 1.58 | 18.96 | 52.74 |

18 | 254.5 | 2.00 | 24 | 41.67 |

20 | 314.2 | 2.47 | 29.64 | 33.74 |

22 | 380.1 | 2.98 | 35.76 | 27.96 |

25 | 490.9 | 3.85 | 46.2 | 21.65 |

28 | 615.8 | 4.83 | 57.96 | 17.25 |

32 | 804.2 | 6.31 | 75.72 | 13.21 |

36 | 1018 | 7.99 | 98.88 | 10.43 |

40 | 1257 | 9.87 | 118.44 | 8.44 |

50 | 1964 | 15.42 | 185.04 | 5.40 |

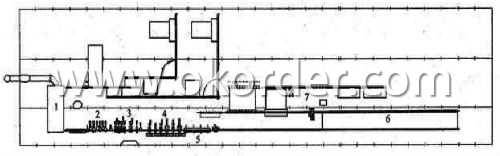

The production process of Steel Rebar

1-Waling beam furnace 2-Roughing rolling group 3-Intermediate rolling train

4-Finishing rolling group 5-Water-cooling device 6-Walking beam cooler

7-Finishing equipment(including the cold scale shear,short feet collection system,

automatic counting device,bundling machine, collect bench)

Usage and Applications of Hot Rolled Deformed Steel Rebars for Constrution:

Deformed bar is widely used in buildings, bridges, roads and other engineering construction. Big to highways, railways, bridges, culverts, tunnels, public facilities such as flood control, dam, small to housing construction, beam, column, wall and the foundation of the plate, deformed bar is an integral structure material. With the development of world economy and the vigorous development of infrastructure construction, real estate, the demand for deformed bar will be larger and larger..

Packaging & Delivery of Hot Rolled Deformed Steel Rebars for Constrution:

Packaging Detail: products are packed in bundle and then shipped by container or bulk vessel, deformed bar is usually naked strapping delivery, when storing, please pay attention to moisture proof. The performance of rust will produce adverse effect.

Each bundle weight: 2-3MT, or as required

Payment terms: TT payment in advance or Irrevocable LC at sight.

Trade terms :FOB, CFR, CIF

Label:to be specified by customer, generally, each bundle has 1-2 labels

Steel Rebar in stock

Note:

1. Our products are produced according to national standard (GB), if not, supply according to national standards (GB) or agreement as customer required.

2. Other Grade and Standard Deformed Steel Bar we can supply:

Grade: GR40/GR60, G460B/B500A/B500B/B500C,BST500S

Standard: ASTM, BS, DIN

The Minimum Order Quantity of these products is high, and need to be confirmed.

3. We can not only supply Deformed Steel Bar; if you need anything about building materials, please contact us for further information.

4. Please send us your detail specifications when inquire. We will reply to you as soon as possible. We sincerely hope we can establish a long stable business relationship.

- Q:What is the difference between hot-rolled and cold-worked steel rebars?

- Hot-rolled steel rebars are produced by heating the steel billet to high temperatures and then passing it through rollers to shape and form it. This process results in rebars with a rough surface and varying dimensions. On the other hand, cold-worked steel rebars are produced by subjecting the hot-rolled rebars to a process called cold working, which involves further shaping and sizing by passing them through dies or rollers at room temperature. This process results in rebars with a smoother surface, tighter dimensional tolerances, and increased strength.

- Q:Are there any limitations on using steel rebars in cold climates?

- Yes, there are some limitations on using steel rebars in cold climates. The main concern is the potential for corrosion due to the presence of moisture, salt, and de-icing chemicals commonly used on roads and bridges during winter. When steel rebars are exposed to these elements, they can rust and weaken over time, compromising the structural integrity of the concrete. To mitigate this issue, several measures can be taken. One common practice is to use epoxy-coated rebars, which provide a protective layer against moisture and chemicals. Additionally, stainless steel rebars can be used, as they are highly resistant to corrosion. However, these options can be more expensive than traditional steel rebars. Furthermore, the construction process in cold climates can also present challenges. Concrete cures and gains strength more slowly in low temperatures, which can impact the overall project timeline. Special precautions, such as heating the concrete or using accelerators, may be necessary to ensure proper curing. It is important to consult local building codes and regulations specific to cold climates to ensure compliance and safety. Engineering professionals experienced in cold weather construction practices can provide valuable insights and recommendations to address the limitations associated with using steel rebars in these conditions.

- Q:What are the guidelines for storing steel rebars on a construction site?

- When it comes to storing steel rebars on a construction site, there are several guidelines that should be followed to ensure safety and maintain the quality of the rebars. Here are some key guidelines: 1. Location: Select a designated area on the construction site that is flat, clean, and well-drained for storing the rebars. Avoid areas prone to flooding or excessive moisture. 2. Elevation: Keep the rebars off the ground by using wooden or concrete blocks to prevent direct contact with soil or water. This helps prevent rusting and corrosion. 3. Stacking: Stack the rebars in a stable manner, ensuring that they are aligned vertically and horizontally to maintain their shape and prevent any bending or warping. Use spacers or crates between layers to maintain proper spacing and prevent entanglement. 4. Protection from elements: Cover the rebars with a waterproof tarp or plastic sheet to protect them from rain, snow, or excessive sunlight. This helps prevent rusting and degradation of the rebars. 5. Separation: Store different sizes and types of rebars separately to avoid mixing or confusion during construction. Clearly label and mark each stack to identify the type, size, and grade of the rebars. 6. Accessibility: Ensure easy access to the rebars for construction workers by organizing them in a logical manner. Place smaller rebars on top for easy retrieval and avoid storing heavy rebars on top of lighter ones to prevent damage. 7. Safety precautions: Maintain a safe distance between the rebars and any heavy machinery or equipment to minimize the risk of accidents. Secure the rebars properly to prevent them from falling or causing injury. 8. Regular inspection: Regularly inspect the rebars for any signs of damage, rust, or corrosion. Replace or repair any damaged or compromised rebars to avoid compromising the structural integrity of the construction project. By adhering to these guidelines, construction sites can ensure the proper storage of steel rebars, promoting safety, efficiency, and the longevity of the rebars.

- Q:What are the different types of couplers used for connecting steel rebars?

- There are several types of couplers used for connecting steel rebars, including mechanical couplers, lap splices, and grouted splices. Mechanical couplers are typically threaded or tapered and provide a mechanical connection between the rebars. Lap splices involve overlapping the rebars and securing them with tie wires or welding. Grouted splices involve placing the rebars in a sleeve or coupling filled with grout to create a bonded connection.

- Q:How are steel rebars marked for identification?

- Steel rebars are typically marked for identification through a combination of embossed letters or numbers, paint markings, or colored plastic caps. These marking methods allow for easy identification and sorting of rebars based on their dimensions, grade, and manufacturer.

- Q:How do steel rebars contribute to the load-bearing capacity of concrete slabs?

- Steel rebars contribute to the load-bearing capacity of concrete slabs in several ways. Firstly, they enhance the tensile strength of the concrete. Concrete is known for its compressive strength, but it lacks the ability to withstand tensile forces. By placing steel rebars within the concrete, it forms a reinforced structure that can resist both compressive and tensile stresses. This prevents the concrete from cracking or failing under heavy loads. Secondly, steel rebars help to distribute the load more evenly across the concrete slab. When a load is applied to a concrete slab, it tends to concentrate at certain points, causing stress concentrations. The presence of rebars helps to spread the load over a larger area, reducing the stress on any individual point and improving the overall load-bearing capacity of the slab. Moreover, steel rebars also prevent the propagation of cracks in concrete slabs. If a crack occurs in the concrete, the rebars act as reinforcement and hold the cracked sections together, preventing the crack from expanding further. This helps to maintain the structural integrity of the slab and ensures its load-bearing capacity is not compromised. In summary, steel rebars play a crucial role in enhancing the load-bearing capacity of concrete slabs by providing tensile strength, distributing loads more evenly, and preventing crack propagation. Their inclusion in concrete structures significantly improves their durability and ability to withstand heavy loads, making them essential components in construction projects.

- Q:Are steel rebars suitable for use in structures with high impact resistance requirements?

- Yes, steel rebars are suitable for use in structures with high impact resistance requirements. Steel rebars are known for their high tensile strength and durability, making them ideal for reinforcing concrete structures that need to withstand heavy impacts. They provide additional strength and stability to the construction, ensuring the structure can withstand various external forces and impacts without compromising its integrity.

- Q:How do steel rebars prevent concrete structures from spalling?

- Steel rebars prevent concrete structures from spalling by providing reinforcement and increasing the tensile strength of the structure. When concrete undergoes temperature changes or experiences external forces, it tends to expand or contract, leading to cracking and spalling. However, with the presence of steel rebars, these forces are distributed throughout the structure, preventing the concrete from cracking and breaking apart. The rebars act as a support system, holding the concrete together and ensuring its stability and durability, thus preventing spalling.

- Q:Can steel rebars be used in foundation systems?

- Yes, steel rebars can be used in foundation systems. Steel rebars, also known as reinforcing bars, are commonly used in concrete structures to enhance their strength and durability. In foundation systems, steel rebars are used to provide reinforcement and prevent cracking or failure of the concrete. They are typically embedded within the concrete to increase its tensile strength and improve its resistance to various external forces such as bending, shearing, and tension. Steel rebars are widely utilized in different types of foundation systems, including shallow foundations, deep foundations, and pile foundations, to ensure the stability and longevity of the structures.

- Q:What are the factors that determine the strength of steel rebars?

- Several factors contribute to the strength of steel rebars. Firstly, the composition of the steel used in their manufacture plays a crucial role. The presence of elements like carbon, manganese, and silicon significantly impacts the steel's strength by enhancing its ability to resist tension and provide structural stability. Secondly, the manufacturing process of rebars influences their strength. Quenching and tempering, a process involving rapid cooling after heating, is typically employed to achieve the desired strength. The precise temperature and duration of this process affect the grain structure and chemical properties of the steel, thereby impacting the rebars' strength. The size and shape of rebars also affect their strength. The diameter and length of a rebar determine its load-bearing capacity. Thicker and longer rebars generally possess higher strength as they can withstand greater stress and distribute it more effectively. Furthermore, the presence of impurities or defects in the steel can weaken rebars. Cracks, voids, or inclusions compromise the structural integrity of the rebar and reduce its strength. Finally, environmental conditions must be considered when determining the strength of rebars. Factors like temperature, humidity, and exposure to corrosive substances can impact their strength over time. Taking precautions, such as using corrosion-resistant coatings or stainless steel rebars, is essential to ensure the longevity and strength of rebars in such environments. In conclusion, the strength of steel rebars depends on the composition of the steel, the manufacturing process, the size and shape of the rebars, the presence of defects, and the environmental conditions in which they will be used. Considering these factors is crucial to ensure the durability and reliability of steel rebars in construction applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Hot Rolled Deformed Steel Rebars for Constrution

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords