Ground Stabilisation Geogrids - High Tensile Plastic Polypropylene Biaxial Geogrid 4m*50m/Roll High for Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Tensile Plastic Polypropylene Biaxial Geogrid 4m*50m/Roll High for Road Consturction

1. Introduction of High Tensile Plastic Polypropylene Biaxial Geogrid 4m*50m/Roll High for Road Consturction

Plastic earthwork grid is a drawing of a square or rectangle of polymer mesh material, according to its manufacture different stretching direction can be unidirectional and bi-stretch. It is in the extruded polymer sheets (raw materials for PP or HDPE) punch, and heating purposes of directional stretch. Unidirectional grid only stretch along plate length direction, which is biaxially oriented grid continues to be one of the grid and then in the direction of its length vertical stretch.

Bx geogrid geogrids are polymers by extruding, forming, punching process after the vertical and horizontal stretch. The material in both portrait and landscape have great tensile strength, this structure in the soil can also provide a more effective commitment and spread the ideals of the chain-like system, adapted to large permanent hosted Foundation

2. Specification of High Tensile Plastic Polypropylene Biaxial Geogrid 4m*50m/Roll High for Road Consturction

Item: GG1515, GG2020, GG3030, GG4040

Polymer: PP

Roll width: 3.95m

Roll length: 50m per roll

Roll weight: 39kgs, 50kgs, 72kgs, 105kgs

Performance: Homogeneous structure, low creep, anti-aging and resisting acid & alkaline

3. Technical Data of High Tensile Plastic Polypropylene Biaxial Geogrid 4m*50m/Roll High for Road Consturction

Index Properties | Test Method | Unit | GG1515 | GG2020 | GG3030 | GG4040 |

MD TD | MD TD | MD TD | MD TD | |||

Polymer | -- | -- | PP | PP | PP | PP |

Minimum Carbon Black | ASTM D 4218 | % | 2 | 2 | 2 | 2 |

Tensile Strength@ 2% Strain | ASTM D 6637 | Kn/m | 5 5 | 7 7 | 10.5 10.5 | 14 14 |

Tensile Strength@ 5% Strain | ASTM D 6637 | Kn/m | 7 7 | 14 14 | 21 21 | 28 28 |

Ultimate Tensile Strength | ASTM D 6637 | Kn/m | 15 15 | 20 20 | 30 30 | 40 40 |

Strain @ Ultimate Strength | ASTM D 6637 | % | 13 10 | 13 10 | 13 10 | 13 10 |

Structural Integrity | ||||||

Junction Efficiency | GRI GG2 | % | 93 | 93 | 93 | 93 |

Flexural Rigidity | ASTM D 1388 | Mg-cm | 700000 | 1000000 | 3500000 | 10000000 |

Aperture Stability | COE Method | mm-N/deg | 646 | 707 | 1432 | 2104 |

Dimensions | ||||||

Roll Width | -- | M | 3.95 | 3.95 | 3.95 | 3.95 |

Roll Length | -- | M | 50 | 50 | 50 | 50 |

Roll Weight | -- | Kg | 39 | 50 | 72 | 105 |

MD denotes Machine direction. TD denotes transverse direction. | ||||||

4. Application of High Tensile Plastic Polypropylene Biaxial Geogrid 4m*50m/Roll High for Road Consturction

Make reinforce treatment for various kinds of soft soil foundation to evenly distribute load stress and reduce uneven settlement, not easy to generate

static elctricity, and flammability property good in the coal mine.

It is easy to wash coal, used in highway, railway, port, airport and municipal project.

support in the recovery working face of coal mine and roadway in the coal mine.

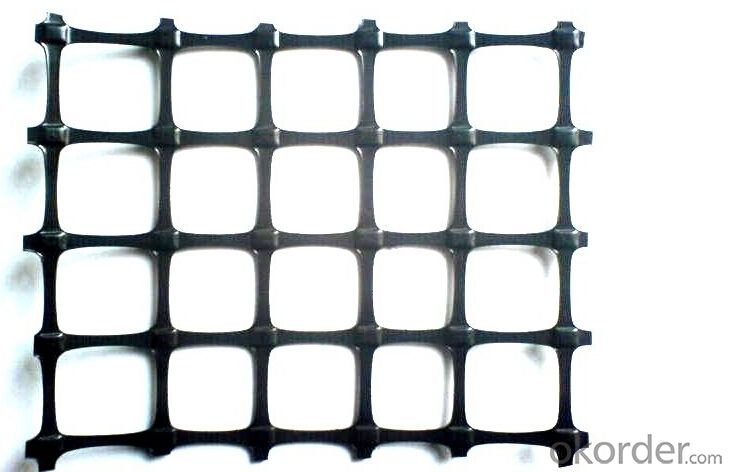

5. Photos of High Tensile Plastic Polypropylene Biaxial Geogrid 4m*50m/Roll High for Road Consturction

- Q: Can geogrids be used in shoreline protection applications?

- Yes, geogrids can be used in shoreline protection applications. Geogrids are commonly used to stabilize soil and prevent erosion, making them an effective solution for protecting shorelines from wave action and water currents. They can be installed in various configurations, such as beneath riprap or as a reinforcement layer for soil, to enhance the stability and longevity of shoreline protection measures.

- Q: How much is the tensile strength of geogrid???????

- Divided into three categories: the overall plastic stretch: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: What is the cost per cubic meter of reinforced earth retaining wall

- The geogrid can be used in other fields, such as garbage disposal, power plant, ash dam project, coal mine, metallurgy, greening, fence and so on

- Q: Are geogrids resistant to UV degradation?

- Yes, geogrids are typically resistant to UV degradation. They are often manufactured using materials that have been treated or designed to withstand exposure to ultraviolet (UV) rays from the sun, ensuring their durability and longevity in outdoor applications.

- Q: Are geogrids suitable for use in mine tailings containment?

- Yes, geogrids are suitable for use in mine tailings containment. Geogrids are commonly used in soil stabilization and reinforcement applications, and their high tensile strength and durability make them effective in preventing soil erosion and improving the stability of mine tailings containment structures. Additionally, geogrids can enhance the overall performance and longevity of the containment system by providing reinforcement to the soil and reducing the risk of slope failure or structural deformation.

- Q: Are geogrids resistant to acid degradation?

- Yes, geogrids are typically resistant to acid degradation.

- Q: Can geogrids be used in ground stabilization for pipelines?

- Yes, geogrids can be used in ground stabilization for pipelines. Geogrids are commonly used in civil engineering projects, including pipeline construction, to reinforce and stabilize the soil. They provide additional strength and stability to the ground, reducing the risk of ground movement and potential damage to the pipelines.

- Q: Are geogrids suitable for reinforcement of soft subgrades?

- Yes, geogrids are suitable for reinforcement of soft subgrades. Geogrids are specifically designed to enhance the stability and strength of weak soils, such as soft subgrades. By distributing the load and improving soil confinement, geogrids can effectively reduce settlement and improve the overall performance of the subgrade.

- Q: Are geogrids suitable for use in mining tailings dams?

- Yes, geogrids are suitable for use in mining tailings dams. Geogrids are commonly used in these applications due to their ability to provide reinforcement, stabilization, and containment of the tailings material. They help to enhance the overall stability and strength of the dam structure, preventing erosion and improving long-term performance. Additionally, geogrids offer cost-effective solutions by reducing the need for excessive amounts of fill material and ensuring the integrity of the dam in mining tailings operations.

- Q: What is the effect of confinement on geogrid performance?

- The effect of confinement on geogrid performance is generally positive. Confinement provides additional support and improves the load-bearing capacity of geogrids. It helps to distribute the load more evenly, reduces lateral movement, and enhances the overall stability of the geogrid system. Confinement can increase the tensile strength and stiffness of the geogrid, allowing it to withstand higher loads and provide better reinforcement.

1. Manufacturer Overview

| Location | 示范:Hebei, China |

| Year Established | 示范:1997 |

| Annual Output Value | 示范:Above US$50 Million |

| Main Markets | 30.00% South America; 20.00% North America; 15.00% Eastern Europe; 15.00% Southeast Asia; 10.00% South Asia; 5.00% Southern Europe; 5.00% Africa |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin;Qingdao;Shanghai |

| Export Percentage | |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 12 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

Ground Stabilisation Geogrids - High Tensile Plastic Polypropylene Biaxial Geogrid 4m*50m/Roll High for Road Construction

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Square Meters m²

- Supply Capability:

- 120000 Square Meters m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords