Geogrids Company Plastic Biaxial Geogrid for Road Construction 15KN-50KN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

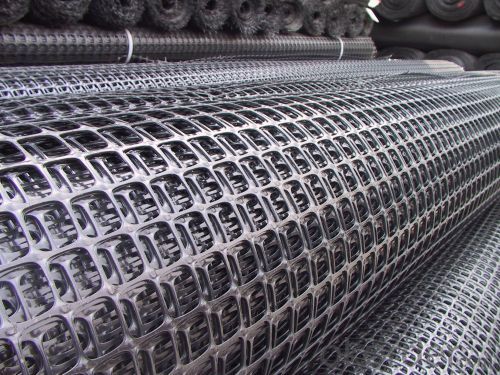

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Biaxial PP Geogrid,

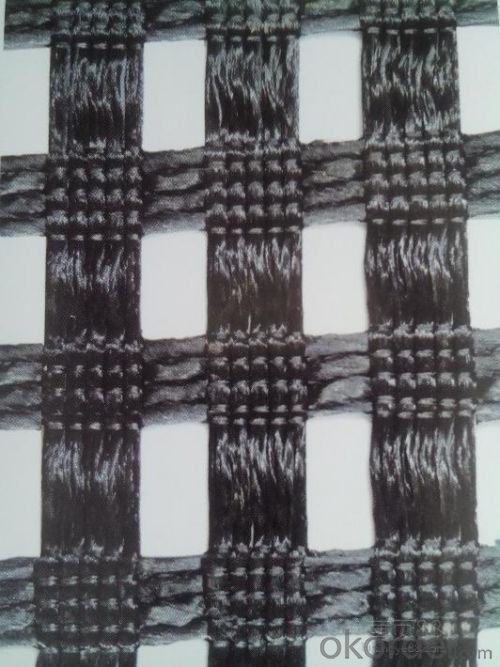

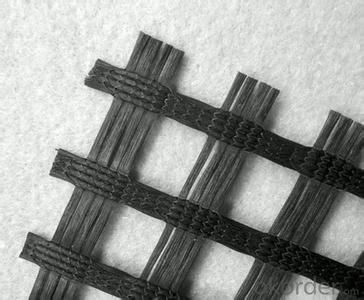

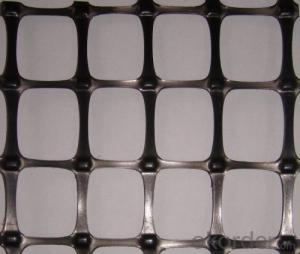

Biaxial geogrids are made of macromolecule polymer by the process of being stretched out, formed into lamella, punched regularly and then longitudinal and transverse elongated. They have much higher longitudinal and transverse tensile strength. These structures can supply alinking system to soil, which be used broadly to enable the permanent bearing capacity of roadbed.

Biaxial Geogrid Features:

1. high tension resistance.

2. high plane torsion resistance modulus.

3. good creep resistance and stable chemical nature.

4. high mechanic damage resistance.

5. reduce filling thickness, improve bearing capacity.

Geogrid Features:

(1)High intension,high tenacity,high occlusive force with soil or gravel,erosion-resistant,

water drainage,light weigth.

(2)Reinforce soft soil roadbed,rib side slope of embankment,enhance isolation,

inhibit ground deformation,prevent crack by reflection,increase strength of roadbed.

Geogrid Usages:

1.Increasing the bearing capacity of roadbed and prolonging its service life.

2.Preventing road surface and foundation from subsiding or cracking and keeping clean and beautiful ground surface.

3.Being convenient for construction,saving time and labor, shortening construction period and maintenance cost.

FAQ:

Q: What is your MOQ?

A: Normally, 1000 m2 per order.

Q: What is your delivery time? Can we have it sooner?

A: 2 days for sample, 3-5 days against 1x40HQ

Q: What is your payment terms?

A: T/T, Paypal (3% surcharge), Western Union or 30% deposit 70% L/C.

- Q: What is the effect of soil type on geogrid performance?

- The effect of soil type on geogrid performance can vary. Different soil types have varying levels of strength, compaction, and drainage capabilities, which can impact the ability of the geogrid to properly reinforce the soil. For example, cohesive soils with high clay content may cause the geogrid to experience reduced tensile strength and limited interlocking capability. On the other hand, granular soils with good drainage properties may enhance the geogrid's performance by allowing better load distribution. Therefore, understanding the soil type is crucial in determining the suitability and effectiveness of geogrid installation for soil reinforcement.

- Q: How do geogrids help in reducing carbon footprint in construction projects?

- Geogrids help in reducing carbon footprint in construction projects by providing reinforcement to soil structures, thereby reducing the need for additional materials like concrete or asphalt. This results in a decrease in the usage of fossil fuel-based materials and the associated carbon emissions during production and transportation. Additionally, the use of geogrids reduces the need for excavation and land disturbance, which further minimizes carbon emissions and the environmental impact of construction projects.

- Q: Can geogrids be used in erosion control applications?

- Yes, geogrids can be used in erosion control applications. Geogrids are commonly used to reinforce and stabilize slopes, retaining walls, and embankments, reducing soil erosion and preventing the loss of soil particles. They provide effective erosion control by improving the stability of the soil and preventing surface runoff, thereby helping to protect against erosion and maintain the integrity of the landscape.

- Q: What are the advantages of using geogrids in ground improvement for seismic stability?

- Using geogrids in ground improvement for seismic stability offers several advantages. Firstly, geogrids enhance the strength and stability of the soil by providing reinforcement. They distribute the applied loads more evenly, reducing the potential for soil settlement and minimizing the risk of ground failure during seismic events. Secondly, geogrids improve the overall bearing capacity of the soil. By confining and interlocking with the soil particles, they increase the shear resistance and prevent excessive lateral movement of the soil, thus enhancing the stability of the ground. Furthermore, geogrids act as a barrier against soil erosion and prevent the loss of soil particles during earthquakes. They help maintain the integrity of the soil structure, reducing the potential for landslides and slope failures. Moreover, geogrids are flexible and adaptable, making them suitable for a variety of ground conditions. They can be easily installed and customized to fit the specific project requirements, allowing for efficient and cost-effective ground improvement solutions. Overall, the use of geogrids in ground improvement for seismic stability offers significant advantages, including enhanced soil strength, improved bearing capacity, erosion control, and adaptability, ultimately resulting in a safer and more stable foundation for structures in earthquake-prone areas.

- Q: Can geogrids be used in reinforcement of mechanically stabilized earth bridge abutments on collapsible soils?

- Yes, geogrids can be used in the reinforcement of mechanically stabilized earth bridge abutments on collapsible soils. Geogrids are commonly used in such applications to enhance the stability and load-bearing capacity of the soil, preventing lateral movement and potential collapse. The geogrids provide additional tensile strength and distribute the loads more efficiently, ensuring the long-term stability and durability of the bridge abutments on collapsible soils.

- Q: What is the lowest price of two-way plastic geogrid?

- The cheapest non-standard 15KN the cheapest price of 2.1 this is the factory with the tax price, the general amount of words, you can also be cheaper

- Q: How do geogrids help in reducing construction material consumption?

- Geogrids help in reducing construction material consumption by providing reinforcement to the soil, allowing for the use of less material in the construction process. They increase the strength and stability of the soil, enabling the use of thinner layers of construction materials such as aggregates or concrete. This results in cost savings and reduced environmental impact due to the reduced use of materials.

- Q: What is the effect of strain rate on geogrid behavior?

- The effect of strain rate on geogrid behavior is that it influences the mechanical properties and performance of the geogrid material. Higher strain rates typically result in increased stiffness and strength, as well as reduced deformation and creep behavior. This is due to the time-dependent nature of geogrids, where faster loading rates induce a more immediate response from the material. Therefore, understanding and accounting for strain rate effects is crucial in designing and predicting the behavior of geogrids in various engineering applications.

- Q: Can geogrids be used in reinforcement of underground pipelines?

- Yes, geogrids can be used in the reinforcement of underground pipelines. Geogrids are commonly used in civil engineering applications to improve the strength and stability of soil. By placing geogrids around underground pipelines, they can effectively distribute the stress and reduce the potential for deformation or failure of the pipelines. Additionally, geogrids can also help to prevent soil erosion and provide long-term reinforcement to ensure the integrity of the underground pipeline system.

- Q: Classification of plastic geogrid

- 2, to highlight the advantages of geogrid is deformation under sustained loading (creep) tendency is very small, creep strength is much better than other materials geogrid, plays an important role in improving the service life of the project.3, the mesh grille and soil interlock and interlock function, constitute an efficient stress transfer mechanism, so that local load can be quickly and effectively spread to a large area of soil, to reduce the local failure stress, improve the service life of engineering.Three, the application of one-way plastic geogrid:Unidirectional plastic geogrid is a kind of high strength geosynthetics. Widely used in dams, tunnels, docks, highways, railways, construction and other fields.

Send your message to us

Geogrids Company Plastic Biaxial Geogrid for Road Construction 15KN-50KN

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 2000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords