Tenax Biaxial Geogrids - Polypropylene Biaxial Tension Plastic Geogrid for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

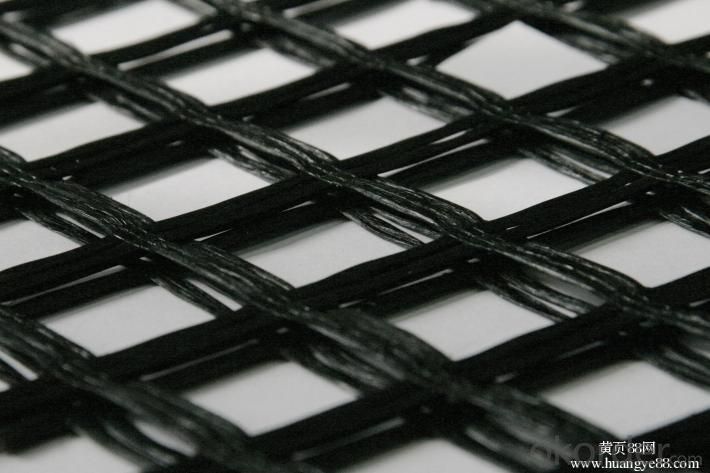

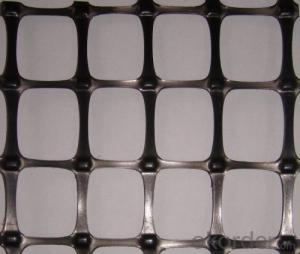

Structure of Polypropylene Biaxial Tension Plastic Geogrid

Polypropylene Biaxial Tension Plastic Geogrid is used widely to increase the asphalt road surface, concrete road and roadbed (both soft and hard road surfaces). Compared with the traditional road surface, it reduces the cost, prolong the service life, and avoid the reflection road crackle.This product is also used to strengthen the soft land, such as railway, airport, irrigation work, and dyke, etc, and the roadbed

Main Features of the Polypropylene Biaxial Tension Plastic Geogrid

High quality asphalt coation

Light weight, high tensile, corrosion resistance

Road maintenance and reinforcement

Packaging & Delivery

| Packaging Details: | PP bags or PE film. Or Packed as customers' requests. |

| Delivery Detail: | 10-20days after the contract is effective |

Polypropylene Biaxial Tension Plastic Geogrid Images

Polypropylene Biaxial Tension Plastic Geogrid Specification

Converting old cement concrete road into composite road.

Restraining reflection cracking caused by block shrinkage.

Preventing and controlling the cracking caused by new and old combination and uneven settlement.

Width:1 ~ 6m

Reinforcement of soft soil foundation and overall strength of roadbed

| Item | Tensile strength(KN/m) | Tensile strength at 2% elongation | Tensile strength at 5% elongation | Nomianal elongation | Products in the range of coal mine | ||

| TGSG15-15 | ≥15.0 | ≥5.0 | ≥7.0 | ≤15.0/13.0 | Fire out time from outer flam(s) | Surface resistivity | |

| TGSG20-20 | ≥20.0 | ≥7.0 | ≥14.0 | ≤3 | <1×109 | ||

| TGSG25-25 | ≥25.0 | ≥9.0 | ≥17.0 | ||||

| TGSG30-30 | ≥30.0 | ≥10.5 | ≥21.0 | ||||

| TGSG35-35 | ≥35.0 | ≥12.0 | ≥24.0 | ||||

| TGSG40-40 | ≥40.0 | ≥14.0 | ≥28.0 | ||||

| TGSG45-45 | ≥45.0 | ≥16.0 | ≥32.0 | ||||

| TGSG50-50 | ≥50.0 | ≥17.5 | ≥35.0 | ||||

FAQ

We have organized several common questions for our clients,may help you sincerely:

Q: How about your company?

A:Our company are one of the largest geosynthetic products supplier in the world.We have the products experience more than 20 years.Already export to USA/Germeny/Australia/Zambia/Brazil etc.more than 20 countries.Almost 10years.Our products including Geocell/Fiberglass Geogrid/Geomembrane/Geotextile/Geonet etc.

Q.Does your products have good qualitity?

A:Yes,we have do many big projects such as the 2008 Beijing Olympic BIRD NEST. Divert water from the south to the north project. And our products have CE certificate also.

Q:How long can we receive the products after purchase?

A:In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 15-20 working days can be delivery.

- Q: How do geogrids enhance the stability of steep highway embankments?

- Geogrids enhance the stability of steep highway embankments by providing reinforcement and confinement to the soil. These grid-like structures are installed within the embankment, creating a stable platform that distributes the load more evenly. This prevents soil erosion, slope failures, and lateral movement, ultimately increasing the overall stability and safety of the embankment.

- Q: How much is the tensile strength of geogrid???????

- Whole plastic stretch type: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: Production of geotextile manufacturers which good

- Nonwoven and woven composite geotextiles:The non-woven fabric is woven with the polypropylene filament woven fabric, and the non-woven fabric is woven with the plastic braiding.

- Q: How do geogrids improve the performance of geocomposite drains?

- Geogrids improve the performance of geocomposite drains by providing enhanced soil reinforcement and stabilization. They help to distribute the load from the surface and reduce stress on the geocomposite drain, preventing it from getting deformed or collapsing. Geogrids also increase the overall strength of the system, improving its longevity and efficiency in draining water or preventing soil erosion.

- Q: How do geogrids help in reducing construction waste?

- Geogrids help in reducing construction waste by providing stability to soil and reducing the need for excessive excavation and material usage. They allow for the use of locally available and low-quality soil, eliminating the need to import expensive and environmentally damaging materials. This reduces the amount of waste generated during construction and helps in preserving natural resources.

- Q: How do geogrids improve soil confinement?

- Geogrids improve soil confinement by providing a strong and stable reinforcement that helps to distribute the load more evenly across the soil. This prevents soil movement and slippage, enhancing the overall stability and strength of the soil.

- Q: Are geogrids suitable for reinforcement of airport runways?

- Yes, geogrids are suitable for the reinforcement of airport runways. Geogrids are high-strength materials that can effectively distribute loads and provide stability to the runway surface. They have been extensively used in civil engineering projects, including airport runway construction, to enhance the strength and durability of the pavement structure. Geogrids help to minimize rutting, cracking, and other forms of distress, improving the overall performance and longevity of airport runways.

- Q: Can geogrids be used in ground stabilization for wastewater treatment plants?

- Yes, geogrids can be used in ground stabilization for wastewater treatment plants. Geogrids are commonly used in civil engineering projects to reinforce soil and provide stability. In the case of wastewater treatment plants, geogrids can be used to reinforce the ground and prevent soil erosion, especially in areas with high water flow or heavy loads. They can improve the stability of the ground and ensure the longevity and effectiveness of the wastewater treatment infrastructure.

- Q: Can geogrids be used in reinforcement of bridge abutments and wing walls?

- Yes, geogrids can be used in the reinforcement of bridge abutments and wing walls. Geogrids are commonly used in civil engineering projects to provide stability and increase the load-bearing capacity of soil. By placing geogrids in the backfill soil behind bridge abutments and wing walls, they can help distribute the loads and prevent soil erosion. This reinforcement technique improves the overall structural integrity of the bridge and enhances its long-term performance.

- Q: What is the recommended installation method for geogrids?

- The recommended installation method for geogrids is to first prepare the ground surface by removing any vegetation and loose materials. Then, the geogrid should be unrolled and laid directly on the prepared ground, ensuring it is properly aligned and flat. It is recommended to use anchor trenches or anchor plates to secure the geogrid in place. Finally, backfill material is placed over the geogrid to provide support and enhance its performance.

Send your message to us

Tenax Biaxial Geogrids - Polypropylene Biaxial Tension Plastic Geogrid for Road Construction

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords