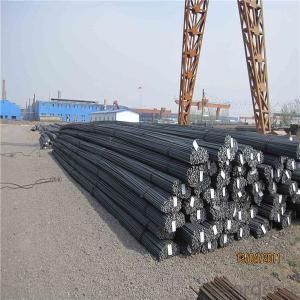

High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,ASTM,JIS,GB,BS,DIN,API,EN

Technique:

Hot Rolled,Cold Rolled,Cold Drawn,ERW,Forged,Saw,Extruded,EFW,Spring

Shape:

U Channel,Square,C Channel,Hexagonal,Round,Rectangular,Oval,LTZ

Surface Treatment:

Galvanized,Coated,Copper Coated,Color Coated,Oiled,Dry,Chromed Passivation,Polished,Bright,Black,PVDF Coated

Steel Grade:

Q195,Q215,Q235,Q215B,Q235B,RHB335,HRB400,200 Series,300 Series,400 Series,600 Series,SS400-SS490,10#,20#,A53(A,B)

Certification:

ISO,SGS,BV,IBR,RoHS,CE,API,BSI,UL

Thickness:

6-34mm

Width:

6-34mm

Length:

12m

Outer Diameter:

6-34mm

Net Weight:

10kg

Packaging:

seaworthy packaging

High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

Details of the High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

| Standard & Grade: | GB1499-98 : HRB335,HRB400,HRB500 |

| BS4449-1997 : GR460,GR500 | |

| CAN/CSA-G30.18-M92 : 400W | |

| ASTM A615 : Gr.40, Gr.60 | |

| Diameter: | 6mm;8mm;10mm;12mm;14mm;16mm;18mm;20mm;22mm;25mm;28mm;30mm;32mm;35mm;40mm |

| Length: | 6m,9m,12m |

| Packing: | Bundle packing |

| Origin: | China |

| Application: | Construction,Road,Machinery processing,Welding fields. |

| Delivery time: | 10-25 days |

| Shipment: | By bulk vessel or Container |

| Documents: | Mill Test Certificate,Commercial Invoice,Packing List,Certificate of Origin |

Company Introduction of the High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery of the High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

| Packaging Detail | Sea worthy packing /as per customer's packing instruction |

| Delivery Detail | 15 ~ 40 days after receiving the deposit |

FAQ

| Are you a trading company or manufacturer? | Manufacturer |

| What’s the MOQ? | 1000m2 |

| What’s your delivery time? | 15-20 days after downpayment received |

| Do you Accept OEM service? | Yes |

| what’s your delivery terms? | FOB/CFR/CIF |

| What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

| Western Union acceptable for small amount. | |

| L/C acceptable for large amount. | |

| Scrow ,Paybal,Alipay are also ok | |

| Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

| What's your available port of Shipment? | Main Port, China |

| What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

| Where are your Market? | Covering more than 160 countries in the world |

- Q: What is the effect of exposure to extreme temperatures on steel rebars?

- Exposure to extreme temperatures can have a significant effect on steel rebars. When exposed to high temperatures, steel rebars can undergo thermal expansion, causing them to expand and potentially lose their original shape. This expansion can lead to cracks, weakening the rebars' structural integrity. On the other hand, exposure to extremely low temperatures can cause the rebars to contract, which may result in stress and potential cracking. Overall, extreme temperature exposure can compromise the strength and durability of steel rebars, posing risks to the structures they support.

- Q: How do steel rebars improve the durability of concrete structures?

- Steel rebars improve the durability of concrete structures in several ways. Firstly, steel rebars act as reinforcement in concrete, providing added strength and stability to the structure. When combined with concrete, the high tensile strength of steel rebars helps to resist cracking and prevent the structure from collapsing under heavy loads or seismic activities. Secondly, steel rebars help to control the formation and propagation of cracks in concrete structures. Concrete is strong in compression but weak in tension, meaning it tends to crack when subjected to tensile forces. By placing steel rebars strategically within the concrete, these cracks are minimized and prevented from spreading, thus enhancing the overall durability of the structure. Furthermore, steel rebars help to improve the resistance of concrete structures against corrosion. Concrete is highly alkaline, which forms a protective layer around the steel rebars, preventing them from rusting. This corrosion resistance ensures that the rebars maintain their structural integrity over time, reducing the risk of deterioration and enhancing the longevity of the concrete structure. In addition, steel rebars also enhance the fire resistance of concrete structures. Due to their high melting point, steel rebars can withstand high temperatures, thereby preventing the concrete from losing its structural integrity during a fire. This added fire resistance ensures that the concrete structure remains stable and safe in the event of a fire, further enhancing its durability. Overall, the inclusion of steel rebars in concrete structures significantly improves their durability by providing added strength, controlling cracks, enhancing corrosion resistance, and increasing fire resistance. These benefits contribute to the longevity and safety of concrete structures, making them more reliable and sustainable in the long run.

- Q: What are the different types of steel rebars used in tunnel constructions?

- Tunnel constructions rely on the use of different steel rebars to strengthen and fortify the tunnels. These rebars play a vital role in providing stability and reinforcement to the tunnel structures. Below are several types of steel rebars commonly utilized in tunnel constructions: 1. Mild Steel Rebars: Also known as black or carbon steel rebars, mild steel rebars are the most frequently employed in tunnel constructions. They are both cost-effective and possess sufficient strength to meet the structural demands of tunnels. 2. High-Strength Steel Rebars: High-strength steel rebars, sometimes referred to as tension steel, offer enhanced tensile strength, making them ideal for tunnels that require high load-bearing capabilities. These rebars are typically fabricated from alloys such as ASTM A615 Grade 80 or ASTM A706 Grade 80. 3. Stainless Steel Rebars: Stainless steel rebars are resistant to corrosion and provide excellent durability in harsh tunnel environments. They are commonly used in tunnel constructions where corrosion protection is vital, such as in marine or coastal areas. 4. Epoxy-Coated Rebars: Epoxy-coated rebars are regular mild steel rebars that have been coated with epoxy to safeguard against corrosion. They are often employed in tunnel constructions that are exposed to moisture, chemicals, or other corrosive elements. 5. Galvanized Rebars: Galvanized rebars are coated with a layer of zinc to shield them from corrosion. They are commonly used in tunnel constructions that are exposed to moisture or in regions with high humidity levels. 6. Fiberglass Rebars: Fiberglass rebars, also known as GFRP (Glass Fiber Reinforced Polymer) rebars, are lightweight and resistant to corrosion. They are used in tunnel constructions where reducing weight is crucial or in areas with high electromagnetic interference. 7. Carbon Fiber Rebars: Carbon fiber rebars, also called CFRP (Carbon Fiber Reinforced Polymer) rebars, possess high tensile strength and are resistant to corrosion. They are often utilized in tunnel constructions that require high tensile strength and resistance to chemical or environmental degradation. Choosing the appropriate type of steel rebar for tunnel constructions depends on various factors such as load-bearing requirements, exposure to corrosion, environmental conditions, and project budget. It is advisable to consult with structural engineers or construction experts to ensure the optimal selection of steel rebars for tunnel projects.

- Q: Are there any limitations on the use of steel rebars in flexural members?

- Yes, there are limitations on the use of steel rebars in flexural members. The size, placement, and quantity of rebars used must comply with the design codes and specifications governing the structural elements. Additionally, factors such as the load capacity, bending strength, and deflection requirements must be considered to ensure the safe and effective use of steel rebars in flexural members.

- Q: What are the benefits of using stainless steel rebars?

- Some benefits of using stainless steel rebars include their high corrosion resistance, durability, and strength. Stainless steel rebars do not rust or corrode like traditional steel rebars, making them ideal for construction projects in areas with high humidity or exposure to corrosive elements. They also have a longer lifespan, reducing the need for frequent replacements and maintenance. Additionally, stainless steel rebars offer better structural integrity and can withstand higher loads, ensuring the longevity and safety of the structures they reinforce.

- Q: How do steel rebars affect the overall noise insulation of a structure?

- Steel rebars have a minimal impact on the overall noise insulation of a structure. This is because noise insulation primarily depends on the density and thickness of the materials used in the construction of walls, floors, and ceilings. Steel rebars, being used to reinforce concrete structures, do not significantly contribute to the sound insulation properties of a building. The primary function of steel rebars is to provide strength and stability to the concrete, ensuring its structural integrity. They are typically embedded within the concrete, resulting in their presence throughout the building's framework. However, the steel rebars themselves do not possess any sound-absorbing or sound-blocking characteristics. To enhance the noise insulation of a structure, other sound insulation materials such as insulation boards, acoustic panels, or soundproofing materials need to be incorporated into the building design. These materials are specifically designed to absorb or block sound waves, reducing the transmission of noise from one area to another. While steel rebars may not directly contribute to noise insulation, they indirectly play a role in maintaining the overall structural integrity of a building. A well-constructed and sturdy structure can help minimize vibrations and sound transmission caused by external noise sources. Therefore, while steel rebars themselves do not significantly affect noise insulation, their presence indirectly contributes to a more solid and stable building, which can help reduce structural vibrations and unwanted noise.

- Q: How are steel rebars transported to the construction site?

- Steel rebars are typically transported to the construction site using flatbed trucks or trailers. These vehicles are specifically designed to carry heavy loads and have the necessary infrastructure to secure and transport the rebars safely.

- Q: How do steel rebars affect the overall maintenance requirements of concrete structures?

- Steel rebars, being strong and durable, enhance the structural integrity of concrete structures. By providing reinforcement, rebars help in distributing the load and increasing the resistance to cracking and tension. This leads to reduced maintenance requirements for concrete structures as they become more resistant to wear and tear, environmental factors, and potential structural failures.

- Q: What are the standard sizes for steel rebars?

- Steel rebars come in various standard sizes, which depend on both the country and industry standards. However, there are some commonly used sizes for steel rebars, such as #3, #4, #5, #6, #7, #8, #9, #10, #11, #14, and #18. These numbers correspond to the diameter of the rebar in inches. For instance, a #3 rebar has a diameter of 3/8 inch, while a #18 rebar has a diameter of 2 1/4 inches. It is worth noting that different countries may employ their own unique sizing systems. Therefore, it is always essential to refer to the local building codes and standards to obtain accurate information regarding steel rebar sizes.

- Q: What is the purpose of using steel rebars in concrete structures?

- The purpose of using steel rebars in concrete structures is to enhance the overall strength and durability of the structure. Concrete, while excellent in compression, is weak in tension. By incorporating steel rebars into the concrete, the structure is able to resist tensile forces and prevent cracking or failure. Steel rebars, which are typically made of carbon steel, are strong and have high tensile strength. They are placed within the concrete forms before pouring, creating a reinforced concrete structure. When subjected to tensile forces, the concrete transfers the load to the steel rebars, which can resist the pulling or stretching forces. This reinforcement helps to distribute the load more evenly, preventing localized stress points and reducing the risk of structural failure. In addition to providing tensile strength, steel rebars also help to control cracks in concrete structures. As concrete shrinks and expands due to temperature changes or drying, it is susceptible to cracking. The presence of steel rebars helps to limit the width and extent of these cracks, ensuring the structural integrity and longevity of the concrete. Furthermore, steel rebars can improve the resistance of concrete structures to seismic activity or other dynamic forces. The flexible nature of steel rebars allows them to absorb and dissipate energy during earthquakes or other vibrations, reducing the risk of collapse. Overall, the purpose of using steel rebars in concrete structures is to reinforce and strengthen the concrete, providing additional tensile strength, controlling cracks, and enhancing the overall durability and resilience of the structure.

Send your message to us

High Tensile Deformed Steel Rebar/Iron Rods for Building Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords