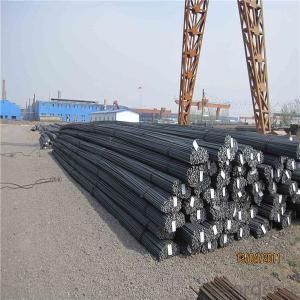

Deformed iron rods for construction building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

steel rebar is metal bars often used in construction for pouring concrete or supporting walls and columns. The

rebar can be smooth, though they are frequently manufactured with deformations that create greater texture to

which concrete can adhere, creating a stronger bond that helps prevent cracking of concrete. These deformations

do not create weaknesses in the rebar, and when rebar is measured to determine its diameter, it is typically measured

at the narrowest point. Strength grades indicate the amount of pressure the steel rebar can withstand, and grade and

diameter are typically presented in both imperial and metric units

Product Description :

Chemical composition (%): | Steel | C | Si | Mn | P | S | Ceq | ||||

HRB335 |

0.25 |

0.80 |

1.60 |

0.045 |

0.045 | 0.52 | |||||

HRB400 | 0.54 | ||||||||||

HRB500 | 0.55 | ||||||||||

Mechanical properties | Steel | Rel/ MPa | Rm/ MPa | A/ % | Agt/ % | ||||||

≥ | |||||||||||

HRB335 | 335 | 455 | 17 |

7.5 | |||||||

HRB400 | 400 | 540 | 16 | ||||||||

HRB500 | 500 | 630 | 15 | ||||||||

Package: | Standard export packing or as customer's request | ||||||||||

Application: | Construction, building, bridge, road. ect | ||||||||||

Payment terms | 1).100% irrevocable L/C at sight. | ||||||||||

Delivery time | 15-30 days after receipt of L/C or deposit by T/T | ||||||||||

Features

1、Pure steel quality, stable chemical contents, small tolerance.

2、Constant Quality, good drawing performance.

3、High dimension accuracy degree, accuracy degree of Level C up to 80%, smooth surface, less scale, easy to be pickled.

4、Automatic bundling with 4 lines by Machine in tidy and good looks

5、Big high quality percentage, small coil percentage, and heavy coil weight for Hard Coil.

6、High sorbitizing percentage.

Packing:

In bundles, each bundle weight 3.5 tons. Load by container or by bulk verssel.

FAQ:

1.Q: What's your MOQ(minimum order quantity)?

A: One full container, mixed acceptable .

2. Q: What's your packing methods?

A: Packed in bundle or bulk ..

3. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

4. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the professional sales team to follow up your case.

5. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q:What are the cost implications of using steel rebars in construction?

- The cost implications associated with the use of steel rebars in construction can vary based on multiple factors. To begin with, the overall construction budget can be affected by the cost of steel rebars themselves. The price of steel rebars can fluctuate due to factors such as global demand, availability of raw materials, and market conditions. Consequently, the cost of steel rebars can differ from one project to another. Furthermore, the quantity of steel rebars required for a construction project will also impact the cost implications. The size, complexity, and load-bearing requirements of the structure will determine the amount of steel rebars needed. Consequently, larger and more intricate projects will necessitate a greater quantity of steel rebars, resulting in increased overall construction costs. Moreover, it is important to consider the installation and labor costs associated with steel rebars. The proper installation and securing of rebars require experienced and skilled labor to ensure structural integrity. The cost of labor can vary depending on the location, availability of skilled workers, and project timeline. Additionally, the handling and cutting of steel rebars may require equipment and tools that can incur additional expenses. Additionally, the long-term cost implications of steel rebars' longevity and durability should be taken into account. Steel is known for its strength, resistance to corrosion, and ability to withstand harsh environmental conditions. By utilizing steel rebars, structures can have a longer lifespan and require less maintenance and repairs over time. This can result in significant cost savings in terms of maintenance and replacement expenses. However, it is also crucial to consider potential cost implications related to sustainability and environmental impact. The production of steel rebars requires substantial energy and resources, which can contribute to carbon emissions and environmental degradation. In some cases, alternative construction materials or methods may provide more cost-effective solutions in terms of sustainability and long-term environmental considerations. In conclusion, the cost implications of using steel rebars in construction are influenced by factors such as the price of steel, the quantity required, labor costs, installation expenses, and long-term durability. While steel rebars offer numerous benefits in terms of strength and longevity, it is essential to consider the specific requirements of the project and balance them with potential economic and sustainability considerations.

- Q:What is the impact of moisture on steel rebars?

- Moisture can have a significant impact on steel rebars. When exposed to moisture, steel rebars can corrode, leading to a loss of structural integrity. Corrosion weakens the rebars, making them susceptible to cracking, rusting, and ultimately compromising the strength of the reinforced concrete structure. Moisture can also accelerate the rate of corrosion, particularly in environments with high humidity or saltwater exposure. To mitigate these effects, proper coating, insulation, and regular maintenance of steel rebars are necessary to protect them from moisture and prevent structural failures.

- Q:How are steel rebars tested for quality assurance?

- Steel rebars are tested for quality assurance through various methods, including visual inspection, dimensional checks, and mechanical tests. Visual inspection ensures that the rebars are free from surface defects, such as cracks or rust. Dimensional checks verify if the rebars meet the required length, diameter, and weight specifications. Mechanical tests, such as tensile and bending tests, assess the rebars' strength and ductility, ensuring they meet the required standards. Additionally, rebars may undergo chemical composition analysis to ensure they contain the appropriate levels of elements like carbon, manganese, and sulfur. These quality assurance tests help ensure that steel rebars are of high quality and suitable for their intended construction applications.

- Q:What is the role of steel rebars in load-bearing structures?

- The role of steel rebars in load-bearing structures is crucial and multifaceted. Steel rebars, short for reinforcing bars, are used to provide reinforcement and strength to concrete structures. They are typically made of carbon steel and are strategically placed within the concrete to counteract its low tensile strength and enhance its ability to withstand tension and compression forces. In load-bearing structures, such as buildings, bridges, dams, and other infrastructure projects, steel rebars play several key roles: 1. Reinforcement: Concrete on its own has excellent compressive strength but lacks tensile strength. Steel rebars are embedded within the concrete to absorb tensile forces and prevent cracks from forming or propagating. By reinforcing the concrete, they help distribute and manage the loads more effectively, ensuring the structural integrity and durability of the building. 2. Load distribution: Steel rebars assist in distributing the weight and load-bearing capacity of the structure more evenly. They help to transfer the applied loads, such as the weight of the structure itself, live loads, or environmental forces, to the foundation or other supporting components. This redistribution of forces prevents localized damage and ensures the structure can handle various external and internal loads. 3. Flexibility and ductility: Steel rebars provide flexibility and ductility to the concrete. This means that even if the structure is subjected to heavy loads, vibrations, or external forces, the rebars can absorb and distribute the stress across the structure, minimizing the risk of failure. Steel rebars are particularly effective in areas prone to earthquakes, where they help to absorb and dissipate seismic energy. 4. Longevity and durability: By reinforcing the concrete, steel rebars significantly increase the longevity and durability of load-bearing structures. They help to prevent cracking, shifting, and other structural issues that may arise due to aging, environmental factors, or excessive loading. This extended lifespan ensures the safety and stability of the structure over time. Overall, steel rebars are crucial components in load-bearing structures as they provide reinforcement, enhance load distribution, increase flexibility, and improve the longevity and durability of the structure. Their inclusion allows for the construction of safer, stronger, and more resilient buildings and infrastructure projects.

- Q:What is the maximum spacing allowed between steel rebars in concrete?

- The maximum spacing allowed between steel rebars in concrete typically depends on various factors such as the structural design requirements, the intended use of the concrete structure, and the specific building codes or standards being followed. However, as a general guideline, the maximum spacing between steel rebars in concrete is often recommended to be within the range of 3 to 6 times the diameter of the rebar.

- Q:What is the carbon content of thread steel?

- The carbon content in the threaded steel is best about 1%, so that it can not only ensure the strength and hardness of the thread steel, but also ensure its plasticity and toughness.

- Q:What are the common sizes of steel rebars used in construction?

- The sizes of steel rebars used in construction can vary depending on the specific application and engineering requirements. However, there are several standard sizes that are widely used in the industry. The industry commonly utilizes rebar sizes ranging from #3 to #18. These numbers represent the diameter of the rebar in eighths of an inch. For instance, a #3 rebar has a diameter of 3/8 inch, while a #18 rebar has a diameter of 2 1/4 inches. Regarding metric measurements, the most frequently used rebar sizes range from 10mm to 40mm in diameter. These sizes are typically designated by their nominal diameter in millimeters, such as 10mm, 12mm, 16mm, 20mm, 25mm, 32mm, and 40mm. The selection of the appropriate rebar size depends on various factors, including the required load-bearing capacity, the structural design, and the type of construction project. Smaller diameter rebars, like #3 or 10mm, are typically utilized in lighter construction projects or for smaller concrete elements like walls or slabs. Conversely, larger diameter rebars, like #18 or 40mm, are commonly employed in heavy-duty applications such as bridges, high-rise buildings, or large-scale infrastructure projects. It is important to note that different countries or regions may have their own specific standards regarding rebar sizes. Consequently, it is crucial to consult local building codes and regulations to ensure compliance.

- Q:What is the process of reinforcing existing concrete structures with steel rebars?

- The process of reinforcing existing concrete structures with steel rebars involves several steps. First, a structural assessment is conducted to determine the areas that require reinforcement. Once identified, the concrete surface is prepared by cleaning and removing any loose or deteriorated material. Next, the rebars are positioned and secured to the existing concrete using epoxy adhesive or mechanical anchors. These rebars are strategically placed to distribute and support the additional load. Finally, the rebars are encased in a new layer of concrete called shotcrete or sprayed concrete, which acts as a protective and bonding layer. The result is a strengthened and more durable concrete structure capable of withstanding increased loads and extending its lifespan.

- Q:How are steel rebars protected against galvanic corrosion in concrete?

- Steel rebars are protected against galvanic corrosion in concrete through the use of various methods, such as epoxy coating, concrete cover, and corrosion inhibitors. These measures create a barrier between the rebar and the concrete, preventing direct contact and minimizing the risk of galvanic corrosion. Additionally, proper concrete mix design and curing techniques can also contribute to reducing the likelihood of corrosion in steel rebars.

- Q:What are the guidelines for reinforcing concrete slabs with steel rebars?

- The guidelines for reinforcing concrete slabs with steel rebars involve several key considerations. Firstly, the rebars should be placed in the lower portion of the slab, typically in a grid pattern, to provide tensile strength and prevent cracking. The spacing and size of the rebars should be determined based on the load and requirements of the specific slab. Additionally, proper lap length and overlap of rebars should be ensured at intersections to maintain structural integrity. Lastly, it is important to follow local building codes and standards to ensure compliance and safety.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Deformed iron rods for construction building

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 17497 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords