Metallic Material Steel Rebar/ Deformed Steel Bar/Iron Rods for Construction Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

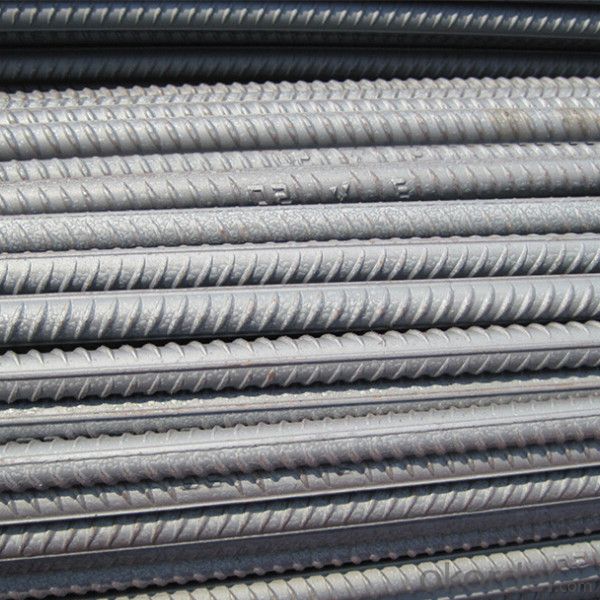

Metallic Material Steel Rebar/ Deformed Steel Bar/Iron Rods for Construction Concrete

Products Description:

Rebar is common known as steel reinforcing bar, usually applied to reinforced concrete and reinforced masonry structures. Formed from mild steel, it is given ribs for better frictional adhesion to the concrete. In other words rebar is an iron rod, a weldable plain reinforcing steel bar, that it can be also used for steel meshes.

1. Diameter: 5.5mm-10mm rounds reinforcing steel bar

10m- 40 rods reinforcing deformed steel bar

2. Length: 6m, 9m, 12m or customized

3. Standard: GB, ASTM, AISI, SAE, DIN, JIS, EN. OEM technology - send detailed technical parameters for accurate quotation.

4. Produce Process: smelt iron - EAF smelt billet - ESR smelt billet - hot rolled or forged to get the steel round bar and plate

5. Heat Treatment: annealing, normalizing, tempering, quenching

6. Surface Treatment: Black

7. Quality Assurance: We accept third party inspection for all orders.

You can ask testing organizations such as SGS, BV, etc. to test our products before shipping.

Theoretical weight and section area:

| Diameter(mm) | Section area (mm²) | Mass(kg/m) | Weight of 12m bar(kg) |

6 | 28.27 | 0.222 | 2.664 |

| 8 | 50.27 | 0.395 | 4.74 |

| 12 | 113.1 | 0.888 | 10.656 |

| 16 | 201.1 | 1.58 | 18.96 |

| 20 | 314.2 | 2.47 | 29.64 |

| 25 | 490.9 | 3.85 | 46.2 |

| 32 | 804.2 | 6.31 | 75.72 |

| 40 | 1257 | 9.87 | 118.44 |

| 50 | 1964 | 15.42 | 185.04 |

Technical Datas:

Grade | Technical data of the original chemical composition (%) | |||||

| C | Mn | Si | S | P | V | |

| ≤0.25 | ≤1.60 | ≤0.80 | ≤0.045 | ≤0.045 | 0.04-0.12 | |

HRB400 | Physical capability | |||||

| Yield Strength (N/cm²) | Tensile Strength (N/cm²) | Elongation (%) | ||||

| ≥400 | ≥570 | ≥14 | ||||

Products Show:

Packages and Shipping:

| Packaging | A seaworthy pachaging or as per customer required |

| Shipping | 10- 30days after we receive 30% deposite |

FAQ:

1. Your advantages?

Professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2. Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3. Payment Terms?

30% TT as deposit and 70% before delivery. Or Irrevocable L/C at sight.

4. Trading Terms?

EXW, FOB, CIF, FFR, CNF

5. After-sale Service

We provide the services and support you need for every step of our cooperation. We're the business partner you can trust. For any problem, please kindly contact us at any your convenient time.

- Q: What are the different types of steel rebars used in bridge construction?

- There are several types of steel rebars commonly used in bridge construction, including carbon steel rebars, epoxy-coated rebars, stainless steel rebars, and galvanized rebars. Each type has its own unique properties and benefits, such as corrosion resistance, strength, and durability, which make them suitable for various bridge construction applications.

- Q: What is the maximum diameter of steel rebars available in the market?

- The maximum diameter of steel rebars available in the market typically ranges from 40 to 50 millimeters.

- Q: Can steel rebars be used in high-temperature applications?

- No, steel rebars should not be used in high-temperature applications as they can lose their strength and structural integrity due to thermal expansion and potential oxidation.

- Q: How do steel rebars affect the durability of concrete in freeze-thaw cycles?

- Steel rebars can greatly enhance the durability of concrete in freeze-thaw cycles. When concrete is exposed to freezing and thawing conditions, it undergoes a cycle of expansion and contraction. During freezing, water inside the concrete pores freezes and expands, exerting pressure on the surrounding concrete matrix. This expansion can lead to cracks and deterioration of the concrete. However, the presence of steel rebars within the concrete can help mitigate these issues. Steel has a much lower coefficient of thermal expansion compared to concrete, which means it does not expand and contract as much with temperature changes. This property allows the steel rebars to absorb the stresses generated during freeze-thaw cycles, preventing significant damage to the concrete structure. Additionally, steel rebars also provide reinforcement to the concrete, increasing its overall strength and toughness. This reinforcement helps to distribute the stresses caused by freeze-thaw cycles more evenly throughout the concrete, reducing the likelihood of cracks forming or propagating. Furthermore, steel rebars act as a barrier against water penetration into the concrete. Moisture is one of the main factors that contribute to freeze-thaw damage. The steel rebars help to create a more impermeable concrete structure by reducing the size and quantity of cracks, preventing water from entering and causing further deterioration. In summary, steel rebars play a crucial role in enhancing the durability of concrete in freeze-thaw cycles. Their ability to absorb stresses, reinforce the concrete, and prevent water penetration significantly reduces the potential for damage and extends the lifespan of the concrete structure.

- Q: How do steel rebars perform in heavy load-bearing structures?

- Steel rebars perform exceptionally well in heavy load-bearing structures. Due to their high tensile strength and durability, they provide crucial reinforcement to concrete, effectively distributing and resisting heavy loads. This ensures structural integrity, preventing deformation and collapse even under extreme conditions.

- Q: Can steel rebars be used in seismic zones?

- Yes, steel rebars can be used in seismic zones. In fact, they are often used to reinforce concrete structures in areas prone to earthquakes. The high tensile strength and ductility of steel rebars make them effective in absorbing and distributing the energy generated during seismic events, thereby enhancing the overall structural integrity and reducing the risk of collapse. Proper design and installation of steel rebars, in accordance with seismic codes and regulations, are crucial to ensure the safety and resilience of buildings in seismic zones.

- Q: How do steel rebars affect the construction cost of high-rise buildings?

- High-rise buildings' construction costs are significantly influenced by steel rebars. These reinforced steel bars are vital for providing strength and stability to the structure, particularly in high-rise buildings that face greater structural loads. To begin with, the cost of steel rebars can make up a substantial portion of the overall construction budget. Market fluctuations affect steel rebars' prices, meaning any increase in steel prices can directly impact construction costs. Additionally, high-rise buildings typically require a higher quantity and quality of rebars compared to low-rise structures, further increasing the overall cost. Furthermore, the installation of steel rebars adds to the construction cost due to the need for skilled labor and specialized equipment. Reinforcing concrete with steel rebars necessitates careful planning, precise placement, and adherence to construction codes and safety standards. Hiring experienced and qualified workers results in higher labor costs. Moreover, the use of steel rebars enhances the durability and longevity of high-rise buildings. By reinforcing the structure, rebars improve the building's structural integrity, making it more resistant to forces like earthquakes, wind, and vibrations. This reduces maintenance and repair costs over the building's lifespan, making the initial investment in steel rebars worthwhile. Lastly, steel rebars impact the overall construction timeline and project schedule. As a critical component of the building's structure, installing rebars is typically time-consuming. Delays or errors in this process can lead to project delays and additional costs. Therefore, proper planning, coordination, and supervision are necessary to ensure the efficient and timely installation of rebars, minimizing any potential cost overruns. In conclusion, steel rebars play a crucial role in high-rise building construction, significantly impacting the overall cost. Despite the direct costs of rebars, labor, and specialized equipment, their use ultimately enhances the building's strength, durability, and longevity. Considering the long-term benefits and the importance of structural integrity, including steel rebars is necessary, despite their impact on construction costs.

- Q: Can steel rebars be used in offshore oil rig construction?

- Yes, steel rebars can be used in offshore oil rig construction. Steel rebars are commonly used in the construction industry, including for offshore structures such as oil rigs. These rebars provide reinforcement to concrete structures, ensuring structural integrity and strength. In the offshore oil rig construction, steel rebars are typically embedded in concrete foundations, columns, and other structural elements to enhance their resistance to various forces such as wind, waves, and seismic activity. The use of steel rebars helps to ensure the durability and safety of offshore oil rigs, making them suitable for the demanding conditions of offshore environments.

- Q: How do steel rebars affect the structural integrity of a building?

- Steel rebars play a vital role in improving the structural integrity of buildings. These reinforced steel bars are mainly used in concrete structures to impart strength and stability. By reinforcing the concrete, rebars assist in withstanding tensile forces and preventing the formation of cracks in the building. Enhancing the overall load-bearing capacity of the structure is one of the primary ways rebars impact structural integrity. The combination of concrete and steel rebars creates a composite material capable of withstanding greater weight and stress. This is especially crucial in tall buildings or structures that need to support heavy loads like bridges or parking garages. Additionally, rebars help alleviate the effects of shrinkage and temperature fluctuations on the concrete. Concrete tends to shrink and expand due to changes in temperature and humidity, which can lead to crack formation and compromise the building's structural integrity. However, by embedding rebars within the concrete, these forces are counteracted, preventing significant damage. Another crucial aspect of rebars is their ability to resist bending and deformation. In the event of an earthquake or other dynamic forces, rebars aid in distributing the energy throughout the structure, reducing the risk of collapse. This resilience proves vital in regions prone to seismic activity. Furthermore, steel rebars offer exceptional durability and longevity. Unlike materials like wood or plastic, steel does not rot, decay, or attract termites or other pests. This ensures that the building's structural integrity remains intact over time, reducing the need for frequent repairs or replacements. In conclusion, steel rebars greatly enhance the structural integrity of buildings. By reinforcing concrete, rebars provide strength, increase load-bearing capacity, resist shrinkage and temperature changes, mitigate the effects of dynamic forces, and offer long-lasting durability. Without the inclusion of rebars, buildings would be more susceptible to cracking, structural failure, and compromised safety.

- Q: What is the international standard for steel rebars?

- The international standard for steel rebars is commonly known as ASTM A615/A615M-20.

Send your message to us

Metallic Material Steel Rebar/ Deformed Steel Bar/Iron Rods for Construction Concrete

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords