High Temperature Resistant Calcium Silicate Pipe 650 Degrees Lightweight

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 7500 m³/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Calcium Silicate Pipe:

It is a microporous structure inorganic hard ultra-light insulation material which is made of inorganic silicon and calcium as materials and treated by special techniques such as high temperature and high pressure hydrothermal reaction. It can maintain high temperature resistance at 650 °C to cope with temperature changes. The stability is long. The ultra-low chloride ion content has a good protection for the pipeline, and the pre-formed anti-deformation greatly enhances the service life.

Product application:

Our calcium silicate pipe are widely used in industries like heat supply network of city construction, metallurgy, petroleum, chemical, electronics, machinery and glass.

Equipment and pipeline facilities for petroleum refining, chemical, hydropower, nuclear power, thermal power, urban power grids

Advantages:

1.Good durability, can bear high temperature within the limit of continuous heat load.

2.Non-deformation within the temperature range.

3.Low thermal conductivity, in the whole range are used with unmatched adiabatic performance.

4.Light weight, high strength. It is the highest in these hard thermal insulation products.

5.Better durability, use for a long time without powder.

6.Construction with ordinary carpenter applicability, tools can be optional cut products.

7.Used safety, hygiene. Excluding asbestos, sulfur, chlorine such poisonous substances.

8.Fear water, but after drying also can be used.

| Calcium Silicate Pipe Size | |||

| Temperature | Size | ||

| ID(Inch) | ID(MM) | Thickness(MM) | |

| 650 or 1050 | 0.5-72 | 23-1836 | 25-100 |

| Other specifications can be customized according to customer requirements | |||

| Calcium silicate pipe index | ||||||

| Items | Unit | KRS-E | KRS-F | KRS-G | KRS-H | |

| Density | Kg/m3 | 220±10% | 220±10% | 250±10% | 850±10% | |

| Pressure Strength | Mpa | ≥0.6 | ≥0.62 | ≥0.72 | ≥17 | |

| Flexural Strength | Mpa | ≥0.35 | ≥0.38 | ≥0.41 | ≥8 | |

| Thermal Conductivity | 100℃ | W/(M.K) | ≤0.055 | ≤0.053 | ≤0.059 | ≤0.095 |

| 200℃ | ≤0.067 | ≤0.064 | ≤0.068 | ≤0.12 | ||

| 400℃ | ≤0.078 | ≤0.072 | ≤0.079 | ≤0.14 | ||

| 800℃ | // | ≤0.171 | ≤0.193 | ≤0.25 | ||

| Temp.Limit | ℃ | 650 | 1050 | 1050 | 1000 | |

| Linear Shrinkage | % | ≤2 | ≤2 | ≤2 | ≤2 | |

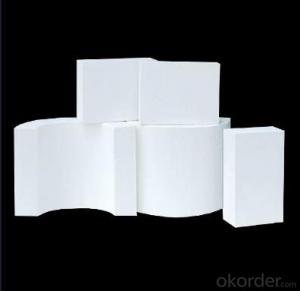

Products Pics:

FAQ:

Q: How can I get the price?

A: We usually quote within 24 hours after we get your inquiry(Except weekend and holidays). If you are very urgent to get the price, please email us or contact us in other ways so that we can offer you a quote.

Q: Can I buy samples placing orders?

A: Yes.Please feel free to contact us.

Q: What is your lead time?

A: It depends on the order quantity and the season you place the order.Usually we can ship within 7-15 days for small quantity,and about 30 days for large quantity.

Q: What is your payment term?

A: T/T,Western Union,L/C,and Paypal.This is negotiable.

Q: What is the shipping method?

A: It could be shipped by sea,by air or by express(EMS,UPS,DHL,TNT,FEDEX and ect).Please confirm with us before placing orders.

- Q: What are the production methods of calcium silicate board material?

- Calcium silicate (microporous calcium silicate) material and calcium silicate board are produced by static steaming method, dynamic hydrothermal synthesis method and two reaction method.

- Q: Which is better, asbestos free calcium silicate and aluminium silicate refractory fiber?

- Aluminum silicate fiber can be divided into many kinds according to the aluminum content, the use temperature range is relatively large, the heat insulation property is good, but the price is more expensive.

- Q: What is the maximum temperature at which the glass is cured?

- The softening point of quartz glass is 1600 degrees, it is sodium phosphate and phosphate. Gas burner 1300 degrees, after homogenization processing, after annealing treatment of glass products.

- Q: What are the high temperature resistant insulation materials at 400?

- According to the general rules of equipment and piping insulation, heat insulation material is a material with a thermal conductivity of less than 0.14W/ (m*K) when the average temperature is equal to or less than 623K (350 degrees Celsius). Heat insulation material is usually light, porous, porous, small thermal conductivity characteristics. Generally used to prevent heat loss of equipment and pipes, or frozen (also known as general cold) and low temperature (also known as cryogenic) use, so in our country, insulation materials, also known as insulation or cold preservation materials. At the same time, because of the porous and fibrous structure of thermal insulation material, it has good sound absorption function, so it is also widely used in the construction industry.

- Q: Calcium silicate board white ICI belongs to wood surface paint?

- ICI can generally be considered as wall paint (latex paint), and latex paint can be used on this kind of cement board. And lumber is different, it is not suitable to brush latex paint on the surface of wood, it can only be decorated with paint (oil paint).

- Q: What are the new energy-saving building materials? What's new?

- Mainly include new wall materials, insulation materials, waterproof sealing materials, ceramic materials, new chemical materials, decoration materials and various industrial waste residue comprehensive utilization.

- Q: What's the use of white portland cement?

- White portland cement as the raw meal with the proper components till the partial melting of the calcium silicate as the main ingredient, the iron content in clinker less addition of gypsum, white water ground made of rigid cementitious material. When grinding cement, allow limestone not to exceed 5% of the cement weight. White cement is mostly ornamental, and its manufacturing process is much better than ordinary cement. The gap is mainly used to hook white tiles, is generally not used in the wall, the reason is not high strength. It is available in the building materials market or decoration materials shop.

- Q: What are the raw materials of cement products? What's the function?

- Water is necessary for the production of cement products, the role of water is to cement hydration. Generally, the water cement ratio of concrete is 0.40~0.65. If the water is too large, it will leave a hole in the concrete, which will affect the strength, density and durability of the concrete and even cause water leakage.

- Q: What is the best price for the use of calcium silicate ceiling?

- The price of each place and labor costs are not the same, here in Heilongjiang labor costs about 18---20 yuan per square meter, plus keel, hanger, calcium silicate board of about 45----50 yuan per square meter.

- Q: How to make building glue?

- The invention relates to an architectural adhesive, which is characterized in that the composition of the building glue comprises 28-50wt% sodium silicate water solution, 34-53wt% quartz sand and 8-35wt% magnesium silicate.Adhesive for a building, it is the following: the weight ratio of 4 to 6, PVA cellulose 6 - 12, 1 - 2, copolymer admixture from 0.01 to 0.05, according to the proportion of polyvinyl alcohol with hot water first fully dissolved, then adding cellulose, copolymer, admixture and stir evenly. The glue can be combined with Portland cement or construction gypsum to cement all kinds of light plates. This product is non-toxic and tasteless, harmless to the human body, is a wide range of uses, superior technical performance of environmentally friendly building adhesive.

Send your message to us

High Temperature Resistant Calcium Silicate Pipe 650 Degrees Lightweight

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m³

- Supply Capability:

- 7500 m³/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches