High Temperature Graphite Coated Fiberglass Fabric Heat Resistant Glass Cloth with Ptfe Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

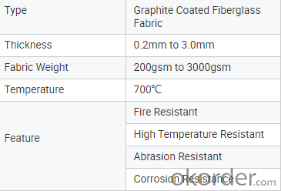

Description: Graphite coated fiberglass Fabric is a unique cloth constructed from base material of fiberglass fabric impregnated with graphite on both sides to increase the temperature resistance capability of the finished product. The coating also improve the performance where flexing is involved. Graphite coated glass cloth is high temperature & corrosion resistant. It also has excellent heat resistance, good abrasion and release properties.

Features: High Temperature And Heat Resistance, Good Abrasion

Application: welding defender, welding blanket ,fire blanket, fire curtain, high temperature, foundry splash protection, heat protection quilts, heat shields, sleeves, connectors and insulation jackets

PRICE: USD7 per square meter

UNIT: square meter

MOQ: 500square meters

Weight: 200gsm-3000gsm or customized

Width: 1m-2m or customized

Yarn Type: E-glass

Standing temperature: 700℃

Product name: Graphite coated fiberglass fabric

Coating/Finish/Surface Treatment: Graphite coated

Roll length: 50 meter or customized

Color: Black

Weave Type: plain woven

Alkali content: Alkali free

Processing service: cutting

Material: fiberglass fabric, Graphite

Thickness: 0.2mm to 3mm

Size: can be customized

Supply ability: 300000 meters per month

Packaging: Graphite coated glass cloth rolls packed in cartons loaded on pallets or according to customers' requirements.

Lead time: 7-30 days

- Q: Is fiberglass fabric resistant to pests and insects?

- Yes, fiberglass fabric is generally resistant to pests and insects. The nature of fiberglass, being made of woven glass fibers, makes it less appealing to pests and insects compared to other materials like cotton or wool. Fiberglass fabric is not a food source for pests, and its smooth and non-absorbent surface makes it less likely for insects to establish a habitat or lay eggs. However, it is important to note that while fiberglass fabric may be resistant to pests and insects, it is not completely immune. In rare cases, certain types of insects or pests may still be able to cause damage to fiberglass fabric, especially if the fabric is already compromised or damaged. Overall, fiberglass fabric is a good choice for those looking for a material that is generally resistant to pests and insects.

- Q: Is fiberglass fabric resistant to chemical degradation?

- Yes, fiberglass fabric is generally resistant to chemical degradation.

- Q: What is the advantage of coating waterproof layer with matrix reinforcing material?

- The large area of carcass can improve the uniformity of waterproof coating thickness. When large-area waterproof coating is applied, the matrix reinforcing material can absorb the coating and play the role of belt feed. In the construction of the side of the material side cloth, because the fabric must be required according to the foot material,And feed to coating evenly, otherwise it will produce the matrix through the impregnation, then need to keep feeding feeding, at the same time in a paint coating on the material quantity and uniformity, to ensure the overall quality of the waterproof layer.

- Q: Can fiberglass fabric be used for making curtains and drapes?

- Yes, fiberglass fabric can be used for making curtains and drapes. Fiberglass fabric is a versatile material that offers several advantages for this application. It is lightweight, durable, and has excellent resistance to heat, chemicals, and moisture. Fiberglass curtains and drapes can provide privacy while allowing natural light to filter through, creating an elegant and modern look. Additionally, fiberglass fabric is easy to clean and maintain, making it a practical choice for curtains and drapes in various settings such as homes, hotels, offices, and hospitals.

- Q: Can fiberglass fabric be used for making filters for air purifiers?

- Fiberglass fabric is a great choice for creating air purifier filters due to its exceptional filtration properties. This material is highly effective at capturing and trapping airborne particles like dust, pollen, pet dander, and other allergens. By using fiberglass fabric filters, you can effectively eliminate these contaminants from the air, resulting in improved indoor air quality and a healthier living environment. Moreover, fiberglass fabric is both durable and resistant to high temperatures, making it perfect for long-lasting usage in air purifiers. However, it's important to be aware that when fiberglass is damaged or mishandled, it can release minuscule particles that may be harmful if inhaled. Therefore, it is crucial to handle and maintain fiberglass filters with caution to avoid any potential health hazards.

- Q: Which is more durable, stone cotton or glass cloth?

- No data connection, I design a variety of heating process, with some experience. You say, 160 degrees brittleness is generally a temperature measurement point and the heat source has a certain distance to show an illusion. The surface of the heat source may have reached a high temperature, and the heating medium is very low. If it is 160 degrees hot air heating, never crack. Welcome to the heating problem.

- Q: Can fiberglass fabric be painted?

- Fiberglass fabric has the ability to be painted. However, in order to ensure proper adhesion, it is crucial to adequately prepare the surface beforehand. This typically entails cleaning the fabric to eliminate any dirt, dust, or oils, and subsequently applying a primer specifically formulated for fiberglass surfaces. Once the primer has dried, it is then possible to proceed with the application of an appropriate paint on the fiberglass fabric. It is imperative to select a paint that is compatible with the particular type of fiberglass fabric being utilized, as well as one that is specifically designed for the intended purpose, whether it be for indoor or outdoor use. Moreover, it is advisable to apply multiple thin coats of paint instead of a single thick coat to attain the optimum outcome.

- Q: Are there any specific safety precautions to consider when working with fiberglass fabrics?

- There are multiple safety precautions to take into account when working with fiberglass fabrics. To begin with, it is crucial to utilize suitable personal protective equipment (PPE) such as gloves, goggles, and a respirator. Minimizing direct contact and inhalation of the fiberglass fibers is essential due to their potential to irritate the skin, eyes, and respiratory system. In addition, it is advisable to either work in a well-ventilated area or employ local exhaust ventilation to decrease the concentration of airborne fiberglass particles. This measure helps in preventing respiratory issues caused by inhaling the fibers. Furthermore, it is important to handle fiberglass fabrics with caution to avoid generating dust or releasing loose fibers. Cutting or sanding fiberglass fabrics should be carried out in a controlled manner by using wet techniques or dust collection systems to reduce airborne particles. When it comes to cleaning up after working with fiberglass fabrics, it is recommended to use a damp cloth or a vacuum cleaner equipped with a HEPA filter to capture any loose fibers. Avoid dry sweeping or using compressed air as these methods can disperse the fibers into the air. Lastly, it is worth noting that storing fiberglass fabrics in a dry area is crucial to prevent moisture absorption, which can negatively impact their performance and durability. By adhering to these safety precautions, individuals can effectively minimize the potential health risks associated with working with fiberglass fabrics.

- Q: Can fiberglass fabric be used for reinforcement in automotive body panels?

- Yes, fiberglass fabric can be used for reinforcement in automotive body panels. Fiberglass fabric is known for its strength, durability, and lightweight properties, making it an ideal material for reinforcing body panels in automobiles. When used in combination with resins or other composite materials, fiberglass fabric can provide the necessary strength and rigidity to withstand the rigors of daily use and protect the vehicle's occupants. Additionally, fiberglass fabric can also be molded into complex shapes, allowing for greater design flexibility in automotive body panel construction.

- Q: What are the different weights per square yard available for fiberglass fabric?

- The weights per square yard available for fiberglass fabric vary depending on the intended use and specific requirements of the project. Generally, fiberglass fabric is available in weights ranging from 0.5 ounces per square yard (OSY) to 8 OSY or even higher. These different weights offer a wide range of options to suit various applications. Lighter weight fiberglass fabrics, such as those around 0.5-1.5 OSY, are ideal for applications that require a lightweight and flexible material. They are commonly used in industries such as aerospace, automotive, and marine for applications such as surfboards, aircraft interiors, and lightweight composite structures. Medium weight fiberglass fabrics, typically around 2-4 OSY, offer a balance between flexibility and strength. They are commonly used in applications like boat construction, wind turbine blades, and sporting goods where a balance between weight and durability is required. Heavier weight fiberglass fabrics, ranging from 5 OSY and above, are known for their superior strength and stiffness. These fabrics are commonly used in applications such as industrial reinforcements, construction, insulation, and high-performance composites. It is important to note that the specific weights available may vary among manufacturers, so it is advisable to consult with suppliers or check their product catalogs to determine the full range of weights per square yard available for fiberglass fabric.

Send your message to us

High Temperature Graphite Coated Fiberglass Fabric Heat Resistant Glass Cloth with Ptfe Coating

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords