High Quality Silion Ferror Slag/Powder Certificate:SGS/CIQ/ISO

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

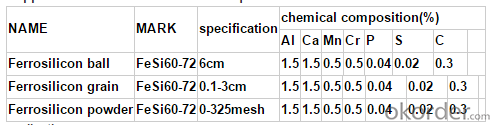

Specifications

1 factory supply directly

2 quality in guarantee

3 timely delivery

4 certificate:SGS/CIQ/ISO

products information

Silicon slag is by-products during the product of ferrosilicon, ferrosilicon slag is used to recycle pig iron and common casting in steel slag and so on, it can improve furnace temperature significantly,increase the liquidity and discharge iron slag effectively, increase the label. stable quality, timely delivery.

Silicon slag is used to recycle pig iron and common casting in steel slag and so on, it can improve furnace temperature significantly,increase the liquidity and discharge iron slag effectively, increase the label. improve the ability of ductile and cutting of pig iron and castings. Stainless steel manufacturers use the silicon slag as reducing agent,during stainless steel smelting process, stable quality, timely delivery.

Application: Steelmaking and Casting

- Q:I am 985 material girls graduated, looking for a job, want to know about

- As a Zhuzhou person, I recommend the Zhuzhou cemented carbide to you, not only because the units are good, but also the city of Zhuzhou is very good. You must have lived here since you worked here. House prices are much lower than in many second tier cities. The standard of living is also good, the large supermarkets are complete, Fantawild is the Southwest's largest amusement park.... Wait

- Q:I would like to solder a carbide tool now, what materials do you need to ask for specific methods?

- You need to use the Ya alloy electrode and welding tool first articles to be heated to red (a temperature of about 800~1000 degrees) and then stained with borax flux (in the electrode when need to add) and then work hard alloy or welded tungsten steel tools a turning tool on the lathe tool holder can be cut off in the car turning bracket that is the

- Q:Import all carbide drill bit, mainly those brands

- Good (maford), Kenna, Thomas, di tex, Sandvik, guhring general in the domestic production, the performance of discount.Now on the market is generally a bit alloy steel material whole bit, although the materials are the same, but due to the processing technology, various brands of product quality disparity. Imported and domestic alloy drills are also very different.Imported alloy bit usually adopts VHM micro grain hard alloy (ISO K40), the type of ultrafine particles (0.6 m) in the application of high performance drill and ordinary milling machine, the hardness and toughness of the ideal together.Take high quality alloy bit surface coating, such as chromium aluminum nitride (AlCrN) coating, the coating layer of coating, the thickness of 4 m, the micro hardness is up to 3200HV, the friction coefficient of 0.35, thermal stability up to 1100 degrees celsius. After coating, the drill color is bluish gray.After coating, the alloy drill can process low alloy steel and high strength steel. High steel can reach 54HRC.

- Q:What brand of carbide is used in woodworking tools?

- Carbide YS2T: is used for low speed roughing and milling of heat resistant alloys and semi finishing of titanium alloys, stainless steels, and low alloy steels. Carbide YL10.2: has high flexural strength and good wear resistance, used in low speed rough car and milling heat-resistant alloy, titanium alloy, also can be processed glass fiber reinforced plastic, making PCB micro drilling and so on. YG3/YG6: is suitable for hard alloy cast iron, nonferrous metals and their alloys and non metallic materials during continuous cutting fine cars, semi refined car, suitable for small section iron fine car, and can be used for the coarse thread, steel, nonferrous metals, wet lubrication tensile alloy wire and non metal wire drilling etc..

- Q:What are the advantages of carbide V-CUT knives and diamond V-CUT knives?

- Precision machining, high finish, sharp blade, machining V groove surface smoothness, no burr burr, greatly improve product quality.Polycrystalline diamond V-CUT knife is now used more and more, and its advantages are: hardness is higher than hard alloy, longer service life, especially in the CNC V-CUT Slitter, the use of good results.

- Q:Processing stainless steel 301 milling thickness of about 3 millimeters, with what blade good?

- You mainly milling the surface is not refined, there is no need to use that good, in one is YS25, cheap, well, that's it, if there is any good advice to my replies

- Q:The existing 60*60 standard cast iron plate, above 3 hard alloy welding specifications, probably in the 30*30, in which the appropriate welding method, know the friends willing to enlighten ah, thanks in advance.Some friends have said the binder is a copper brazing, the basic can be settled. As far as I know, many methods such as welding, high frequency welding, oxygen welding, I want to find a kind of welding method. The key is to understand the trouble with us, surface and surface welding

- Light of copper is not enough, but also a deoxidizing agent, is the most commonly used colophong powder. In addition, there must be a certain level of operation, because I have seen a lot of welding ordinary turning tools, in the work of the alloy head always fall.

- Q:Carbide yk20? What do you mean?

- Cemented carbides YK20, Y represent alloy categories - tungsten cobalt, K20 represents cobalt contentDensity g/cm3:14.30-14.60;The hardness of HRA is more than or equal to 86.5;The shear strength is greater than or equal to N/mm2:2350,Performance and usage: with high toughness and wear resistance, suitable for embedding percussive rotary drilling bit, drilling in hard and tight hard rock.

- Q:The difference between cemented carbide YG 15 and yg12

- Material introduction: YG3X 14.6-15.2 132092 is suitable for high speed finish machining of cast iron, non-ferrous metal and alloy, hardened steel, alloy steel and small cutting section. K01 YG3X YG6A 14.6-15.0 137091.5 is suitable for semi hard finishing of hard cast iron, non-ferrous metals and their alloys. It is also suitable for semi finishing and finishing of high manganese steel, quenched steel and alloy steel. K05 YG6A YG6X 14.6-15.0 142091 has been proved by the production and use that the alloy can be used to process chilled alloy cast iron and heat-resisting alloy steel. It can also achieve good results and is also suitable for the finishing of ordinary cast iron. K10 YG6X YK15 14.2-14.6 210091 is suitable for processing integral alloy drilling, milling, reaming and other cutting tools. It has high wear resistance and toughness. K15 K20 YK15 YG6 14.5-14.9 138089 is suitable for semi finishing with medium casting speed of cast iron, non-ferrous metals and alloys, non-metallic materials. K20 YG6 YG6X-1 14.6-15.0 150090 is suitable for cast iron, nonferrous metals and alloy non metal material during continuous cutting finishing, discontinuous cutting the semi refined car, fine car, small section fine car, coarse thread, continuous section semi finishing milling and finish milling, rough and fine hole expansion. K20 YG6X-1 YG8N 14.5-14.8 200090 is suitable for high speed cutting of cast iron, white cast iron, nodular cast iron, and chrome, nickel and stainless steel.

- Q:allowing the use of larger anterior angle, generally high speed steel tool than the hard alloy tool angle _______.A0 degrees ~5 degrees, B6 degrees, ~10 degrees, C11 degrees, ~15 degrees

- In the car, titanium alloy, high speed steel cutting tool rake angle to 20 degrees angle than the carbide cutter. However, different the material should choose different rake angles, and not a fixed angle value.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High Quality Silion Ferror Slag/Powder Certificate:SGS/CIQ/ISO

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products