High-Quality FRP Roofing Panel for Corrosion-Resistant Roofing Tile and Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

Name | FRP Roofing |

Material | Fiberglass |

Width | 880mm/1050mm |

Effective width | 800mm/960mm |

Wave length | 160mm |

Wave height | 30mm |

Pitch | 220mm |

Thickness | 3/2.5mm |

Length | Customized but must be a multiple of wave pitch |

Color | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ | 1000 Square meter |

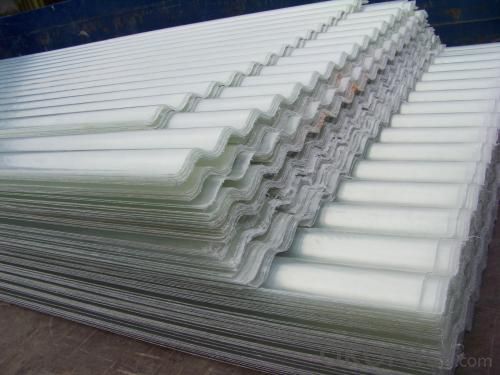

PICTURES

- Q: Can FRP roofing panels be used for bus shelters?

- Yes, FRP roofing panels can be used for bus shelters. FRP (Fiberglass Reinforced Plastic) panels are commonly used in construction due to their lightweight, durable, and weather-resistant properties. These panels are ideal for bus shelters as they provide protection from the elements, including rain, wind, and UV rays, while also allowing natural light to pass through. Additionally, FRP panels are easy to install, low maintenance, and have a long lifespan, making them a suitable choice for bus shelter applications.

- Q: Do FRP roofing panels require special handling during transportation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require special handling during transportation. FRP panels are lightweight and fragile, so they can be easily damaged if not handled properly. It is important to ensure that the panels are securely packaged and protected from any potential impacts or rough handling during transportation. Additionally, FRP panels should be stored and transported in a horizontal position to prevent warping or bending. Care should also be taken to avoid excessive exposure to direct sunlight or extreme temperatures, as this can cause damage to the panels. Overall, special attention and care should be given to the handling of FRP roofing panels to ensure their integrity and prevent any potential damage during transportation.

- Q: How do FRP roofing panels perform in high winds?

- FRP roofing panels are designed to withstand high winds due to their durable and lightweight composition. Their strong construction and ability to flex under pressure help to prevent damage and minimize the risk of detachment during storms or strong gusts. However, it is important to ensure proper installation and maintenance to optimize their performance in high winds.

- Q: Do FRP roofing panels have any specific building code approvals?

- FRP roofing panels are required to have specific building code approvals, which can vary depending on the region or country. Each jurisdiction may have its own regulations and standards. However, in general, FRP roofing panels must meet certain criteria to receive these approvals. The building code approvals for FRP roofing panels typically consider factors like fire resistance, wind uplift resistance, impact resistance, and structural stability. These approvals ensure that the panels can withstand different environmental conditions and contribute to the safety and stability of the building. Manufacturers of FRP roofing panels must comply with the relevant building codes and standards set by local regulatory bodies to obtain building code approvals. This usually involves rigorous testing and certification processes conducted by independent testing laboratories. These tests assess the panels' performance in scenarios like fire exposure, wind pressure, and impact resistance. Builders and contractors should verify the specific building code approvals of FRP roofing panels before using them in construction projects. This can be done by checking the manufacturer's product documentation, which should clearly state the obtained approvals and certifications. By ensuring that FRP roofing panels have the necessary building code approvals, construction professionals can have confidence in their safety and performance. It helps them comply with local building codes and regulations and promotes the overall quality and longevity of the roofing system.

- Q: Can FRP roofing panels be used for outdoor structures like sheds or pergolas?

- Yes, FRP roofing panels can definitely be used for outdoor structures like sheds or pergolas. FRP (fiberglass reinforced plastic) roofing panels are known for their durability and resistance to weather elements, making them an ideal choice for outdoor applications. They are lightweight, yet strong, and can withstand harsh weather conditions such as rain, snow, and UV rays without deteriorating or losing their structural integrity. Additionally, FRP roofing panels are easy to install and maintain, making them a practical and cost-effective option for outdoor structures.

- Q: Are FRP roofing panels compatible with different roof insulation materials?

- Yes, FRP roofing panels are compatible with different roof insulation materials. They can be used with various types of insulation such as polyisocyanurate, expanded polystyrene, or mineral wool, providing a versatile solution for different roofing systems.

- Q: Can FRP roofing panels be used in museums or cultural institutions?

- Museums and cultural institutions can utilize FRP (Fiberglass Reinforced Plastic) roofing panels. These panels possess durability, strength, and corrosion resistance, making them an ideal option for such environments. In order to withstand varying weather conditions like extreme temperatures, UV exposure, and moisture, museums and cultural institutions often seek roofing materials that can endure. Compared to other roofing materials, FRP roofing panels are lightweight, resulting in easier installation and handling. This advantage proves beneficial when faced with specific architectural requirements or limitations. Moreover, FRP panels can be produced in numerous colors and finishes, providing design flexibility to complement the aesthetics of the museum or cultural institution. When opting for FRP roofing panels in museums or cultural institutions, it is important to consider the potential for light transmission. Certain FRP panels are designed to allow natural light to pass through, positively impacting the display of artwork or artifacts. However, it is crucial to ensure that the light transmission properties of the panels do not have a negative impact on the conservation or preservation of delicate items. In conclusion, FRP roofing panels offer durability, corrosion resistance, and design flexibility, making them a suitable choice for museums or cultural institutions. Nonetheless, it is crucial to evaluate the specific requirements of the institution, such as light transmission, before selecting the appropriate FRP panels for the project.

- Q: Are FRP roofing panels prone to warping from heavy machinery?

- The durability and resistance to warping of FRP roofing panels are well-known. However, exposure to heavy machinery may result in warping, depending on various factors. To begin with, the resistance to warping of FRP roofing panels is greatly influenced by their thickness and quality. Thicker panels with a higher fiberglass content are less likely to warp under heavy machinery loads compared to thinner or lower-quality panels. Additionally, the type and weight of the heavy machinery can affect the probability of warping. While FRP panels can withstand normal loads like snow or wind, excessive weight from heavy machinery can surpass their load-bearing capacity and potentially cause warping. Moreover, the condition of the underlying support structure is crucial. If the structure is weak or incapable of handling the weight of heavy machinery, it can create localized pressure points on the FRP panels, increasing the risk of warping. Proper installation is also vital in preventing warping. Inadequate fastening of the panels or gaps and uneven pressure distribution during installation can contribute to warping, particularly under heavy machinery loads. To minimize the possibility of warping, it is advisable to seek guidance from a professional roofing contractor with expertise in FRP installations. They can evaluate the specific requirements of the roofing project, taking into account the type and weight of machinery involved, and recommend suitable panel thickness, quality, and installation techniques to ensure maximum durability while minimizing the risk of warping.

- Q: Can FRP roofing panels be installed on flat roofs?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on flat roofs. FRP panels are lightweight and versatile, making them suitable for various roofing applications, including flat roofs. These panels are designed to provide excellent resistance to weathering and UV radiation, ensuring durability and longevity. Additionally, FRP roofing panels can be easily installed on flat roofs using adhesive or mechanical fasteners, depending on the specific requirements of the roof. Overall, FRP roofing panels offer a cost-effective and efficient solution for flat roof installations.

- Q: How do FRP roofing panels perform in terms of energy efficiency?

- FRP roofing panels are known for their excellent energy efficiency performance. Their composition, typically consisting of fiberglass reinforced plastic, allows for effective insulation and heat reflection. This helps to minimize heat transfer and reduce energy consumption for cooling or heating purposes, resulting in lower energy bills. Additionally, FRP roofing panels often have high light transmission properties, which can reduce the need for artificial lighting during the day, further enhancing their energy efficiency.

Send your message to us

High-Quality FRP Roofing Panel for Corrosion-Resistant Roofing Tile and Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 22 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords