High-Quality Electric Arc Furnace Graphite Electrodes with Nipple

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Graphite Electrode

Graphite electrode is made from the domestic first petroleum coke and high quality needle coke

and widely used in the electric arc furnaces for production of alloy steels, metal and other

nonmetallic materials, etc. The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode. The range of diameters covers from 200mm to

700mm. Our products own the following characteristics: low electric resistance, good electric and

thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

Product Applications:

It is used for the electric arc furnace steel making. (About 70-80% graphite electrode is used for steel making).

It is used for the submerged arc furnace, including melting iron alloy, pure silicon, yellow

phosphorus,matte, calcium carbide and so on.

It is used for the resistance furnace, such as the graphite making, melting glass, silicon carbide

making and so on.

Product Advantages:

28 drums counter-flow calcining furnace

Auto-control dosing system

Germany Enrich kneading system

3500MT vertical tamping&horizontal extruding press

Auto-comtrol ring backing furnace

Germany Feist-incon 2nd Baking Kiln

High pressure imprgnation system

Acheson high power DC graphitizing furnace

Japan Nachi NC electrode machining line

America lngersoll NC electrode machine line

Japan Nachi NC nipple machining line

Carbon fiber production line

Main Product Features:

Good electrical conductivity

High resistance to thermal shock

High mechanical strength

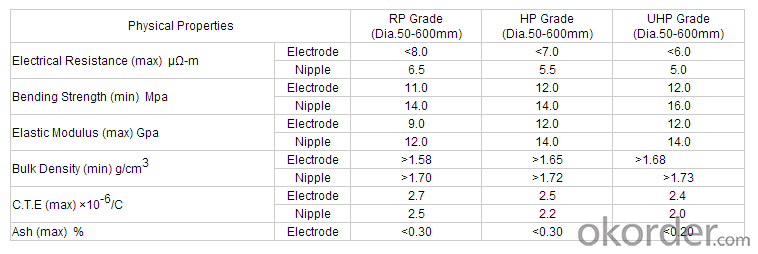

Product Specifications:

FAQ:

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition

and Physical properties. After production, all the goods will be tested, and the quality certificate

will be shipped along with goods.

2. What's your delivery time?

It usually needs about 20days- 45 days after receiving the deposit.

3. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock,

The quantity based on the material type, The buyer should bear all the shipping costs.

4. What's your payment terms?

We can accept 30% deposit, 70% balance before shipment for ordrs over $ 2000.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

6. What standards do we have?

Our products meet the standards, such as ASTM, ASME, AMS, DIN, JIS etc.

The third party testing is all available for us.

Product Picture

- Q: Classification, uses and manufacturers of graphite electrodes

- The difference between graphite electrodesMainly from the current, density, resistance, bending strength, ash parameters are measured

- Q: What is the striking electrode in the die making? Where is the technical point?

- The electrode in die processing is edm.The discharge produces sparks and forms a "corrosion" to the other pole. The method of machining parts (dies) using this phenomenon is called edm.

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- There are many factors that determine the need to continue producing graphite electrodes, so high-speed machining has become a key manufacturing process in the die manufacturing industry. Compared with the time required for the milling of graphite electrodes, the processing of high rigidity hard steel still takes longer. When milling dies, cavities, and complex 3D surfaces on hard steel, radial runout errors and tool deviations often result in fracture of the tool. When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material.

- Q: Use of graphite in steelmaking

- Application of graphite electrode in smelting, alloy steel, iron alloy, graphite electrode, the strong current through the melting zone, the arc electrode into the electric furnace, the electrical energy into heat, the temperature rises to 2000 degrees Celsius, so as to achieve the purpose of melting or reaction.

- Q: What is the difference between pyridine type nitrogen and graphite type nitrogen?

- High purity graphite is said to produce graphite electrode, ash is very low, generally below 10 million.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode has good electrical and chemical stability. It has high mechanical strength, low impurity content and good vibration resistance at high temperature. It is a good conductor of heat and electricity. Qingdao Chenyang graphite graphite electrode quality is good, they are a direct manufacturer of graphite electrode. Hope to be of some help to you.

- Q: The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- In addition, the infiltration of water on graphite is not good, can not get the effect of dust removal. Now there are special graphite machine, sealing system. Air-cooled can be used, after all, the best air-cooled.

- Q: Why is graphite a negative pole and copper is an anode?

- The process of causing a chemical change by passing through a substance. Chemical change is the process in which material is lost or obtained by electrolysis (oxidation or reduction). Electrolysis is performed in an electrolytic cell. The electrolytic cell is composed of two electrodes, yin and Yang, which are respectively immersed in the solution containing positive and negative ions. The current into the negative electrode (cathode), are positively charged ions migrate to the cathode solution, and with the combination of electronic elements, become neutral or negatively charged molecules; negative ion transfer to another electrode (anode), electrons are given into neutral elements or molecules.

- Q: How can I electroplate iron? I would like to use graphite as an electrode. Iron is plated on graphite with iron solution, so it can be processed into iron parts. I wonder if it can be done

- Iron plating can be, with 2 valence iron, but on the graphite joint force is good, it is difficult to say, electroplating is bad, peeling is also common. Relatively speaking, iron parts on nickel plating is relatively simple, also more applicable

- Q: What is anodized graphite?

- Electrochemical graphite is made of graphite, coke and other raw materials, placed in the high temperature of more than 2500 degrees in the furnace, processed into products.

Send your message to us

High-Quality Electric Arc Furnace Graphite Electrodes with Nipple

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords