Graphite Electrode with Good Quality Hot Sale for Electric Arc Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Graphite Electrode

Graphite electrode is made from the domestic first class petroleum coke and high quality needle coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc. The Graphite electrodes include: regular power, high power, ultra high power and square electrode. The range of diameters covers from 200mm to 800mm. Our products own the following characteristics: low electric resistivity, good electrical and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanical shock, high mechanical strength, high machining accuracy.

CNBM and its partner have 4 production bases and the annual production capacity of graphite electrodes is 60,000 MT.

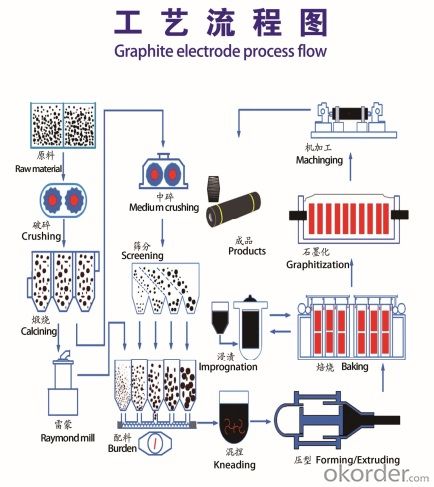

Graphite Electrode Process Flow

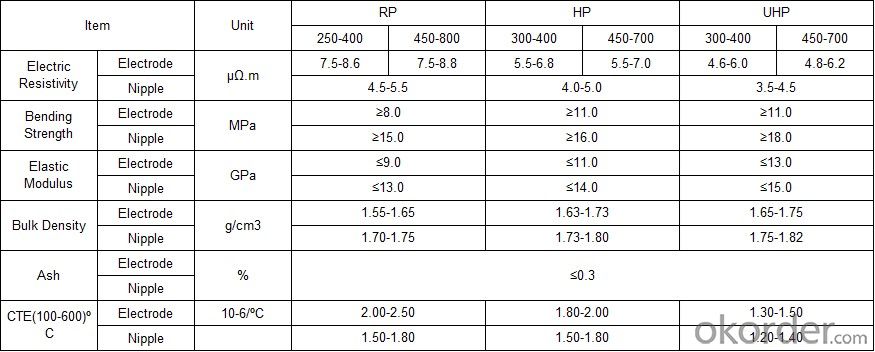

Technical Specifaication:

Company Profile

CNBM INTERNATIONAL CORPORATION

Build your world with our materials.

We are a primary subsidiary of China National Building Material Group Co., Ltd.

CNBM Group is a central government-owned enterprise and a Fortune Global 500 company (Ranking 203th in 2019). It is the largest building material manufacturer and service provider in the world, with 15 publicly-listed companies and over 180,000 employees (2019). We have more than 300 factory plants in China. For the refractory, we are top 3 in China. We have more than 17 plants in different cities.

Workshop

Quality Assurance & Control

· National Certified Laboratory

· Key testing instruments, including: specific resistor, bulk density meter, elasticmodulus meter, bending strength inspector, ash analysis meter, CTE analysis meter, etc.

· On-time instrument calibration

· On-site properties testing, including:

L-CTE,C-CTE

Specific resistance, bulk density,

Bending strength, ash content, elastic modulus

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your requirement.

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material. Considering the foreseeable future, the graphite electrode will occupy a high position, usually used equipment for processing graphite electrode the highest efficiency mold manufacturers will unremittingly, expand and between those determined to use the hard steel processing manufacturer competition gap. The foundation of micro cutting tools, in terms of graphite electrodes, is one of its most magical words: "high speed."". The spindle speed of the high speed machining center is up to 30000~60000r/min, and the feed speed can be increased to shorten the processing period and improve the quality of the surface and edge. The motor needed to drive this type of spindle is relatively small and light, which helps to reduce cutting power and reduce tool breakage. This is critical because many of the electrodes are complex, and their production involves small, easily broken micro tools (see Figure 1).

- Q: Does the silicon carbide heat plant require a fine structure graphite electrode? What kind of graphite products do you need?

- Silicon carbide graphite is very famous for its high hardness and wear resistance. It is generally used in high wear resistance machinery industry and high wear resistant sealing industry.

- Q: Graphite electrode specifications, graphite electrode manufacturers which good?

- Graphite electrode to Qingdao Chenyang graphite Co., quality assurance, trustworthy, we have been purchasing graphite electrode for them, you can ask them,

- Q: Will the brush grease not short-circuit the commutator?

- Graphite, on the other hand, has good lubrication. The graphite base electrode will form a layer of carbon film when it rotates on the surface of the motor commutator. It can reduce the friction coefficient between the brush and the commutator and reduce the wear of the commutator effectively.

- Q: What is the role of the Pt electrode? What is the difference between the graphite electrode and the graphite electrode?

- Carbon electrodes, however, are less likely to be less controllable because of their microstructure, or have some effect on the electric field, if they are sensitive signals

- Q: What kind of asphalt is better for natural graphite coating?

- The graphite electrode includes: (1) ordinary power graphite electrode. Allows the use of current density below 17A / cm 2 graphite electrode, mainly used for steelmaking, smelting silicon, refining yellow phosphorus, such as ordinary power furnace. (2) oxidation resistance coating graphite electrode. A graphite electrode coated with an antioxidant protective layer is applied to form a protective layer that is conductive and resistant to oxidation at high temperature, thereby reducing electrode consumption during steelmaking. (3) high power graphite electrode. A graphite electrode with a current density of 18 ~ 25A / cm 2 is allowed to be used as a high power arc furnace for steelmaking. (4) ultra high power graphite electrode. Permits use of graphite electrodes with current densities greater than 25A / cm 2. Mainly used in ultra high power steelmaking arc furnace.

- Q: How should carbon deposits be treated?

- In this way, can keep the engine seal, to prevent oil because the gap is too large and rampant, buried carbon curse generation "".

- Q: Graphite graphite graphite graphite electrode what is the use?

- Of course all conductive graphite gray, conductive powder is used for professional conductive, the conductivity is different, in order to achieve its electrical resistance value, the graphite powder of different particle by the ratio to reach the ideal value of resistance. Graphite powder is pure graphite powder, requirements of mesh consistent, high purity.

- Q: What are the factors that affect the electrode wear rate of machine tools?

- In the pulse peak voltage, current and pulse width decreased, the electrode loss increase, and the heat produced from the processing of large pulse width, is conducive to the adsorption of copper electrode graphitization induced by carbon, which is commonly referred to as the covering effect".

- Q: What does graphite electrode GSK mean?

- Graphite board material is GSK, GSK refers to model specifications

Send your message to us

Graphite Electrode with Good Quality Hot Sale for Electric Arc Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 700 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches