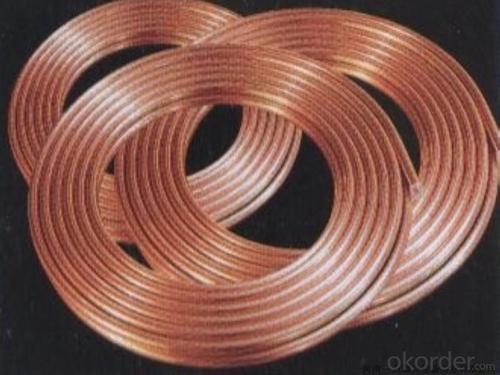

High Performance Refrigeration Copper Pipe for Refrigeration Devices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name:High Performance Refrigeration Copper Pipe for Refrigerating

| Model: | P2、TU1、TU2、T2 |

| Brief: | Mainly used in refrigerating system of air conditioners; high precision and pressure-resistant product manufactured through extrusion, rolling, drawing, surface treatment, and heat treatment, usually processed into finned refrigeration pipe and other refrigeration devices. |

Type Specificationss:

Item | air conditioner copper pipe |

Type | straight copper pipe,pancake coil copper pipe,capillary copper pipe |

Standard | GB/T1527-2006,JIS H3300-2006,ASTM B75M,ASTMB42,ASTMB111,ASTMB395, ASTM B359,ASTM B188,ASTM B698,ASTM B640,etc |

Material | C10100,C10200,C10300,C10400,C10500,C10700,C10800,C10910,C10920, C10930,C11000,C11300,C11400,C11500,C11600,C12000,C12200,C12300, C12500,C14200,C14420,C14500,C14510,C14520,C14530,C17200,C19200, C21000,C23000,C26000,C27000,C27400,C28000,C33000,C33200,C37000, C44300,C44400,C44500,C60800,C63020,C65500,C68700,C70400,C70620, C71000,C71500,C71520,C71640,C72200,etc |

Shape | Round,Square,Rectangular,Oval,half-round |

Outside diameter | 4.76-28.58mm |

Wall thickness | 0.4-1.5mm |

Length | 1m,2m,3m,6m,or as required |

Hardness | 1/16 hard,1/8 hard,3/8 hard,1/4 hard,1/2hard,full hard,soft,. |

Surface | mill,polished,bright,oiled,hair line,brush,mirror,sand blast,or as required |

Price Term | Ex-Work,FOB,CNF,CFR,CIF etc |

Payment Terms | TT,L/C etc |

Export to | Singapore,Indonesia,Ukraine,Korea,Thailand,Viet Nam,Saudi Arabia,Brazil,Spain,Canada, USA,Egypt,Iran,India,Kuwait,Dubai,Oman,Kuwait,Peru,Mexico,Iraq,Russia,Malaysia,etc |

MOQ | 2 tons |

Package | Standard export package ,or as required. |

Application | Copper pipe have strong, corrosion resistant properties, and become a modern contractor in all of commodity house pipes, heating, cooling water piping installation of choice |

Contact | If you have any question ,please feel free to contact me we are sure your inquiry or requirements will get prompt attention |

Usage: Mainly used in refrigerating system of air conditioners; high precision and pressure-resistant product manufactured through extrusion, rolling, drawing, surface treatment, and heat treatment, usually processed into finned refrigeration pipe and other refrigeration devices.

Production Equipment

750-1500kg main frequency induction copper melting furnace, 80MN water seal extruder, LG60 high speed two-roll cold pilger mill, straight-line wire-drawing machine, copper tube/pipe straightener, polisher, 84′ copper coil winding machine, straightening-cutting & pancake coiling machine, thermoplastic packaging machine, 1.2T continuous bright annealing furnace.

80MN extruder

Continuous bright annealing furnace

Testing Devices

spectrum analyzer, atomic absorption analyzer, spectrophotometry, analytical balances, metallurgical microscope, eddy current flaw detector, metal tensile testing machine, eddy conductivity instrument.

Hardness tester

Spectrum analyzer

Metallurgical microscope

Metal tensile testing machine

Atomic absorption analyzer

Process

refined copper — smelting & casting — extrusion — rolling — drawing — straightening-cutting/forming of pancake coil — bright annealing — packaging — finished goods.

Standards

GB/T 1527-2006 Drawn tube of copper and copper alloys

GB/T 16866-2006 Dimensions and tolerances of copper and copper alloy seamless tubes

GB/T 4423-2007 Copper and copper-alloy cold-drawn rod and bar

GB/T 5231-2001 Wrought copper and copper alloys chemical composition limits and forms of wrought products

GB/T 5585.1-2005 Copper or aluminium and its alloy bus bars for electrical purposes—Part 1:Copper andcopper alloy bus bars

GB/T 17791-2007 Seamless copper tube for air conditioner and refrigeration equipment

GB/T 19850-2005 The seamless round copper tubes for electrical purposes

GB/T 26024-2010 Seamless copper and copper alloys tube for valves on air-conditioning and refrigeration system

ASTM B280-2008 Standard Specification for Seamless Copper Tube for Air Conditioning and Refrigeration Field Service

EN 12735-1:2001 Copper and copper alloys Seamless,round copper tubes for air-conditioning and refrigeration Part 1:Tubes for piping systems

EN 12735-2:2001 Copper and copper alloy – seamless round copper tube/pipe for air-conditioning and refrigeration system – for equipment

JIS H3300-2009 Seamless copper and copper alloy tube/pipe

- Q: Air conditioning copper tube packaging broken after being soaked in rain on air-conditioning?

- Hanging insulation pipe, a general 1.8 meters, retail 2 to 3 yuan a, 1.5p is small, is 6, big is generally 12. The price is about the same. The bandage is 1.5 to 3 yuan. One roll can be used to wrap the wall air conditioner standard tube completely. Bandage with broken cotton insulation is very vulnerable to ultraviolet damage, within a year powdering, air-conditioning power loss increased. Affect machine life. Hope to help you.

- Q: I have fiberglass wrap to insulate my pipes, what I want to know--do I pull the wrap tight that sort of flattens the insulation or do I pull the wrap just tight enough that it doesn‘t flatten the insulation?

- The front. If there's no traction where the power is you're not going to go anywhere, now will you?

- Q: I have some copper pipes used for forced hot water heat that run in an unheated area behind an upstairs wall. I want to insulate the pipes because the heat they throw off cause ice dams on my roof, and also, I want to save money by keeping the heat in and prevent them from possibly freezing. I‘ve seen three types of insulation for pipes:- a styrofoam kind that is very cheap in price.- a rubber kind that is expensive but looks to be higher quality.- a fiberglass kind that is just a bit less expensive than the rubber kind.I‘m not sure what is the best type to keep the heat in the pipes and protect them from freezing as well.

- The Greenish marks are flux which was used to solder the copper joints. It is harmless and usually appears about a couple of months after soldering. it can be cleaned off easily.

- Q: A little background:I am building a spud gun to shoot nerf darts, and I need to know what size pipe would be best for my project.And yes, I am set on copper because I love the SteamPunk look!

- You need your whole brake system to be checked out calipers discs rotors master brake cylinder fluid . and would be ergent about this one.

- Q: i have to do a homework sheet on copper. one of the questions is "Name the naturally occurring isotopes of copper." I HAVE NO IDEA! and if you could explain, that would be great!

- at the same time as your prof may well be a nitwit, there is not any excuse for having problems with very trouble-free stuff which you will desire to have discovered to do in severe college chemistry or can truthfully locate on your textbook. in case you anticipate your prof to be like a severe college instructor, you would be disenchanted. Chlorine has 2 for sure happening isotopes, one in all mass 34.97 amu and the different of mass 36.97 amu. locate the fractional abundances............ that's solved by making use of the weighted sum eqtn. If X is the fraction of Cl-35, then a million-X is the fraction of Cl-37. Then 35.40 5= SUM( fraction x weight ) the place the sum is for the two isotopes. final question. Multiply the DIAMETER of a million.66A-gadgets by making use of the atoms. sounds like approximately 2.7x10^22 A-gadgets . Now convert to something greater effective (10-13 km/Ao) and to miles.

- Q: In a vandalized home, is it better and/or cheaper to replace the copper pipe or replace with PVC?

- PVC is cheaper these days because copper is outrageous. Copper is more forgiving in places that may freeze in winter. PVC is quicker to connect at joints, too. Be sure to insulate all water supply with something appropriate between it and the outside wall.

- Q: Is this video fake or do I just suck at science?

- The magnet moving near the copper causes a force that acts as a brake, slowing its natural motion down the pipe due to gravity. Where does the force come from? Electric currents and magnetic fields are closely related. If you have one, you often have (or can make) the other. The braking force in the demonstration is due to an eddy current. That's an electrical current that forms in the copper, in response to the moving magnetic field of the falling neodymium magnet. That eddy current produces a magnetic field of its own. The two magnetic fields overlap and slow the fall of the magnet.

- Q: what type of copper pipe is used for water lines in a home?

- fluid will be bypassing in the master cylinder,rekit or replace

- Q: my plumbing in my house is copper and starting to get tiny holes in it.

- Highly acidic water can do that, but you'd notice the taste. It would be very sour. That's about the only thing that can really harm copper water lines. Electrolysis can cause similar problems, but you'd have to be directly charging the plumbing system with a AC/DC rectifier for that to really be a factor. I guess my answer is that I don't know. Poor quality copper to begin with? A freeze event that didn't just outright split the pipe but thinned the walls? Suffice it to say, but you have a very rare and expensive condition.

- Q: i want to magnatite a copper vessel.....i mean if i want to convert copper into magnet, what chemical shall i use, i heard that , ferrous oxide will do the work..but if so, what is the melting point and where do i find this chemical in india...pls give me full details

- You can't make a magnet out of copper. Only Iron and Nikkel (and their alloys, and less often derived chemicals from these) can be magnetised, and it is not a chemical process. Rather it is done by exposing them to a strong magnetic field. ferrous oxide (Magnetite) is an Iron compound that is naturally magnetic. It can be mixed with other chemicals to make a magnetic fluid, but I am not sure whether can be made to dry and stick to another surface. If it does, the object will no longer look like it's made of copper. The best you can do is to coat your vessel in a thin layer of Iron or Nikkel, and then magenetise it (by stroking it with another magnet). But then you might have the same problem, your vessel will not look like copper. If you go through all this trouble you can just as well use magnetic paint. I am not sure were to get that in India, but it is available here (in South Africa) in DIY shops. People buy it to paint walls in a kids playroom, so that they can write on it with cryons, and stick magnetic objects to it.

Send your message to us

High Performance Refrigeration Copper Pipe for Refrigeration Devices

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords