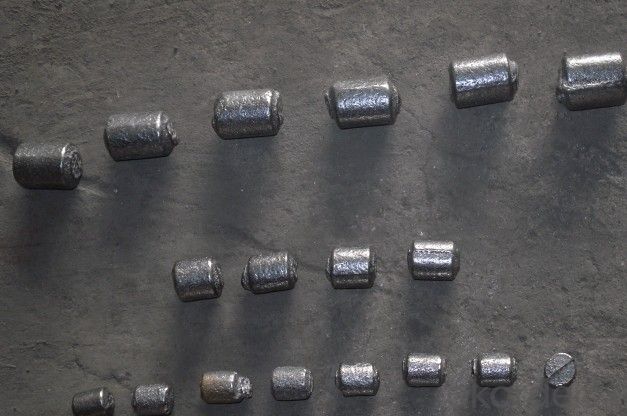

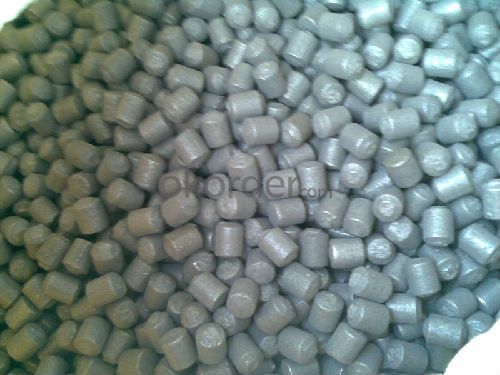

High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant and Mine

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant

and Mine:

1:Wear-resistant,No breaking, Good hardness

2:Certification: ISO9001

3:10X15mm-45X60mm

4:Hardness: HRC45-65

5:Cr: 0.8-22%

Feature of High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant and

Mine:

Even Hardness,

No breakage,

Good wear resistance,

High impact value.

Applied Field of High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant

and Mine:

1) Cement Plants, Mines,

2) Power stations,

3) Chemical Industries,

4) Grinding mill.

Chemical Composition of High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement

Plant and Mine:

Type | Hardness | Chemical Elements | |||||||

C | Si | Mn | Cr | Mo | Cu | S | P | ||

Low Cr Grinding Cylpebs | ≥HRC45 | 2.6-3.5 | 0.2-1.5 | 0.3-1.5 | 0.8-1.8 | Minim | Minim | ≤0.15 | ≤0.15 |

Middle Cr Grinding Cylpebs | ≥HRC52 | 2.3-3.3 | 0.2-1.5 | 0.5-2.2 | 2.5-8.5 | Minim | Minim | ≤0.12 | ≤0.12 |

High Cr Grinding Cylpebs | |||||||||

- Q: Is the cast steel a casting part?

- Cast steel is one of the casting parts that you call. The material is made of carbon steel or alloy steel, stainless steel, etc. the method is cast

- Q: What is the difference between casting and stamping parts?

- Separation process is also called blanking, the purpose is to make the stamping parts along a certain contour line from the sheet metal separation, at the same time guarantee the quality requirements of the separation section. Stamping is a highly efficient production methods, the use of compound die, especially the multi station progressive die stamping process can be completed in a multi machine, realized by belt uncoiling, leveling, punching, forming and finishing automatic production. High production efficiency, good working conditions, low production costs, can produce hundreds of parts per minute.

- Q: As shown, how do I achieve the tightness test of this product, and achieve industrial production? Seek expert advice.

- Precise and tight sealing of the surface to which the test piece is to be tested, equipped with an airtight test instrument, and an electrical control system. You can complete automated testing equipment

- Q: Would you please tell me how to use casting parts for a year?The cast of an aircraft wing needs to be put aside for a year before it breaks;Does anyone know why?

- There are various casting stresses after casting, which can be divided into two kinds: thermal stress and shrinkage stress. In a long time placed in the atmosphere, called aging treatment.Aging treatment is an effective measure to eliminate casting stress. Aging is divided into natural aging, thermal aging and resonance aging.1, the so-called natural aging, the casting is placed in the open field for more than half a year, so that the internal stress relief.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: What kind of flaw detector is better for casting parts?

- Casting using the detector test, you must first determine the detection process, such as the detection of surface and near surface crack defects, such as casting, recommended by CYD-3000, or CYD-5000 mobile magnetic testing machine for testing.

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: When there is no flaw detection for large casting parts, is there any crack inside?

- Cracks are considered serious levels of defects and should be repaired

- Q: Why should pig iron be used in casting?

- Not necessarily is iron, steel, stainless steel, aluminum, copper can be cast iron, is cheaper, and better properties of cast out, for example, is not easy to rust, high strength, easy processing and so on, and is the only iron iron cast out, it is not necessarily the raw pig iron, plus some other material

- Q: How to solve casting defect casting?

- Different defects, different solutions, some shortcomings, the current domestic level can not be resolved

1. Manufacturer Overview

| Location | Shandong,China |

| Year Established | 2000 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | Domestic Market, South Asia, Southern Europe, Northern Europe, Central America |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 10-20 People |

| Language Spoken: | English;Chinese; |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Grinding Balls; Grinding Rods; Grinding Cylpebs. |

| Product Price Range | Average |

Send your message to us

High Chromium Alloyed Casting Grinding Cylpebs with High Hardness for Cement Plant and Mine

- Loading Port:

- Qingdao Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MTS m.t.

- Supply Capability:

- 200000MTS/Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches