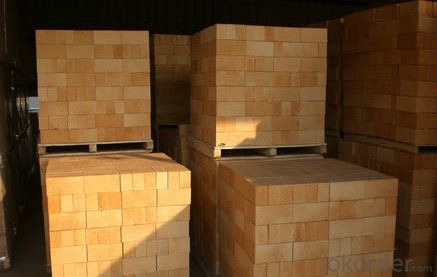

High Alumina Magnesite Brick for Cement and Glass Plant

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of Magnesite Brick

Magnesite Brick for Cement and Glass Plant are designed and manufactured as per the different usage parts and working conditions of electric furnace, converter and ladle. Magnesite Brick is shaped by high purity & high compact or large crystalline fused magnesia and high purity graphite as main materials and phenolic resin as binder.

Magnesite Brick is mainly applied for the lining parts of electric furnace and converter. Directly touching molten steel and slag, Magnesite Brick has the advantages of high strength, high slag resistance, good thermal stability and high refractoriness.

Specifications for Magnesite Brick

| Product Item | Magnesite Brick for Cement and Glass Plant | |

| KBL-65 | KBL-75 | |

| Al2O3 % | >65 | >75 |

| Fe2O3 % | 2.0 | 2.0 |

| Refractoriness °C | 1790 | 1790 |

| Apparent porosity % | 24 | 24 |

| Bulk density g/cm3 | 2.45 | 2.55 |

| Cold crushing strength Mpa | 45 | 55 |

| Refractoriness under load KD,°C | 1500 | 1520 |

| Reheating Linear Change % | 1500°C×2h (0.1~-0.2) | 1520°C×2h (0.1~-0.4) |

| Thermal shock resistance ,times (1100°C water cool) | 18 | 15 |

| Application | Industrial furnace temperature sharp parts | Industrial furnace temperature sharp parts |

Features of Magnesite Brick

Low bulk density, low thermal conductivity, good thermal insulation performance.

Refractory category allow direct contact of fire, suitable for various atmosphere.

Good integrity with furnace lining, long service life, easy operation, could be shaped freely.

Typical Application of Magnesite Brick

Furnaces of metallurgy industry, heat treatment furnace.

Furnaces of chemical industry and construction industry.

Furnace of incineration of garbage, recirculating fluidized bed furnace .

- Q: What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

- Q: What are the specific raw materials for plastic pallets?

- There are two kinds of raw materials for plastic pallets: one is polypropylene (PP) and the other is polyethylene (HDPE).Plastic pallets for logistics storage: pp+pe material, recycled material 10%;Plastic trays for food trays: food grade PP, PE, pc;Polyethylene (HDPE) has excellent impact resistance and cold resistance, and it can resist environmental stress cracking. Excellent chemical stability, good oil resistance. Water absorption and tiny, low permeability, organic vapor transmission rate is larger. Electrical insulation is good, in all frequency range, dielectric properties are extremely excellent.

- Q: How are the high alumina bricks fired?

- Generally, the high alumina bauxite is added with a small amount of clay. After being ground, the gas is injected and shaped in the form of slurry by the way of gas attack or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used to replace part of bauxite clinker. Used for lining and thermal insulation of masonry kilns, as well as for areas where there is no high temperature, high melting material erosion and erosion effects. When touching the flame directly, the touch temperature shall not be higher than 1350 degrees.

- Q: What materials are used for roof insulation?

- There are two kinds: one is a kind of cotton insulation board, such as rock wool board, aluminum silicate cotton board, but this is not environmental protection, harmful to life, foam board (this fire safety factor minimum), these relatively cheap.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- 75 high aluminum and 43 clay bricks, 75 single weight 4.5kg or more. 43 3.65kg or so, the use of temperature 75, high aluminum in about 1520, 43 of brick 1430 or so, the color of 75 pan white, 43 of the Loess color. In short, the difference is great.

- Q: How much is one ton / ton of high alumina refractory brick?

- The market price of about super high aluminium brick price at 3000 yuan / ton, a high aluminum brick at around 2500 yuan / ton, two high aluminum bricks at around 2100 yuan / ton three grade high alumina bricks at around 1850 yuan / ton for reference, choose to buy the area is not the same as the prices are not the same.

- Q: The difference between ordinary and diatomite brick refractory brick

- To say the difference, the material is the biggest difference. There are diatomite brick density, compressive strength of small brick kiln belongs to the outer thermal insulation, and heavy refractory brick kilns for multi village in direct contact with the flame, high temperature resistance, good compressive strength, but no insulation. Hope to help you.

- Q: How does the physicochemical index change when the high alumina brick is used at high temperature?

- If the range of softening temperature exceeds the load, the constants of other physical and chemical indexes will also increase or decrease.

- Q: The difference between clay bricks and clay bricks

- According to the hole rate: solid brick (no hole or hole rate less than 25% bricks), porous brick (hole rate is equal to or greater than 25%), the size of the hole is small and the number of bricks, usually used in load-bearing parts, higher strength level. Hollow brick (hole rate equal to or greater than 40%, large pore size and small amount of brick, commonly used in non load parts, low strength grade).Solid bricks and porous bricks are mostly used for load-bearing structural walls. Hollow bricks are mostly used in non load bearing structures.

- Q: High alumina brick 80 with which high aluminum cement?

- Which kind should be chosen should be determined according to the conditions of use, life expectancy and cost control. By the way, the quality of masonry is also very influential.

Send your message to us

High Alumina Magnesite Brick for Cement and Glass Plant

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords