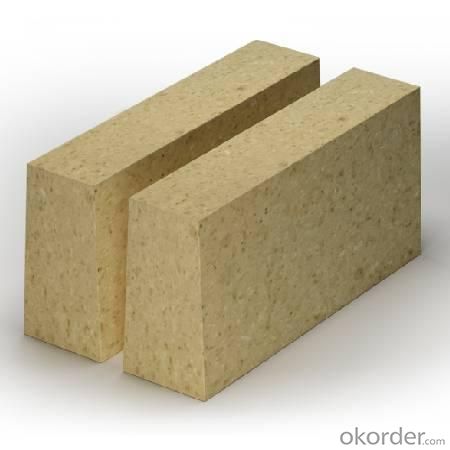

High Alumina Brick - Standard and Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

CNBM fire brick is an alumina-silicate refractory material in which the Al2O3 content is more than 55%, and is calcined from a high-content alumina raw material such as a silicone raw material or a bauxite. High heat resistance and high temperature resistance at 1770 ° C and above. Has good slag resistance, mainly used in the masonry of steelmaking electric furnace, glass furnace, cement rotary furnace and so on.

Standard sizing: 230 x 114 x 65 mm ,Special size and OEM Product Data Service also provide!

Packing and Shipping

Packaging : Fire brick Packed by sea-worthy wooden pallet + shrink wrapped + carton

For example, Standard size of refractory brick : 230x114x65mm

Shipping : 384pcs/plt x 18plts in one 20 feet container;

Common Product Data:

project | first-class | Second class | Third class | highest |

LZ-75 | LZ-65 | LZ-55 | LZ-80 | |

AL2O3 %≥ | 75 | 65 | 55 | 85 |

Fe203 % < | 2.5 | 2.5 | 2.6 | 2.0 |

Bulk Density g/cm³ | 2.5 | 2.4 | 2.3 | 2.6 |

Cold Crushing Strength MPa > | 70 | 60 | 50 | 80 |

Refractoriness Under Load ℃ | 1510 | 1460 | 1420 | 1550 |

Refractory temperature ℃ > | 1790 | 1770 | 1770 | 1790 |

Apparent Porosity % < | 22 | 23 | 24 | 21 |

Refiring linear change % | -0.3 | -0.4 | -0.4 | -0.2 |

Products Pics

Why us

Professional fire brick manufacturer. We have being specialized in producing refractory fireclay brick for more than 40 years so that we can guarantee a stable quality.

Guaranteed quality. Our production process conforms strictly to the requirements of ISO9000 quality management system. Quality inspection is carried out in every links of our production. SGS third party inspection is available.

Sound after sales service. We provide sound after sales service. We provide 24 hours’ consultation service. We are ready to answer your consultations at any time.

Main products as follow:

1)Various industrial furnace series refractories

High-alumina brick, anchor brick, clay brick, lightweight insulation brick, high-strength diatomaceous earth brick, low-iron mullite brick, silica brick

2)Heat storage balls for various industrial furnace regenerators

Special corundum heat storage balls, honeycomb, regenerator block, tapping chute brick,Anti-stripping high-alumina bricks for cement industry, alkali-resistant bricks, phosphate bricks, etc.

3)Industrial furnace and power generation boiler industry with various brands of wear-resistant bricks, corundum brick, mullite bricks and other stereotypes.

4)Wear-resistant castables, corundum castables, low-cement high-strength castables, impervious materials, self-flowing materials, plastics, and other unshaped refractories.

Products exported to the United States, India, Japan. South Korea, Pakistan and other countries.

- Q: How much is the bending temperature aluminum silicon carbide brick for torpedo car

- The product has the advantages of high temperature, little creep, strong corrosion resistance and good thermal shock resistance, and is suitable for large and medium-sized hot blast stoves.

- Q: What's the difference between high alumina refractory bricks and high alumina refractory bricks?

- High alumina refractory brick in all thermal shock properties except performance are better than clay refractory brick, masonry in furnace and thermal equipment, such as clay bricks can be competent the work environment is not high aluminum brick masonry.

- Q: What is the price of the first grade high alumina brick?

- The specifications and different prices, relatively large fluctuations of the main push of the refractory Dongxin high alumina brick high alumina brick prices generally around 3000 have various levels of Dongxin refractories

- Q: How to reduce porosity of high alumina brick

- In order to reduce the porosity of high alumina brick, the corresponding measures should be taken from the selection of raw materials, batching, mixing, molding and firing.

- Q: Which is better, the soft core or the hard core?

- The wire has two kinds of hard core and soft core, the hard core line is only one wire core, and the soft core line has a plurality of wire cores. For the same sectional area, the 7 core is more than the more than 30 core. There is a difference in use. Generally used for DC is the use of hard core line, because of its small line consumption; and for communication, we should use soft core line, but also in order to reduce its line consumption

- Q: What kinds of minerals are there in the five major categories of ore crystal chemistry?

- Sulphide. A total of more than 200~300 kinds, followed by the type of silicate minerals, the weight of 0.25% of the crust. Chang Fu is an important nonferrous metal deposit, which is an important source of copper, lead, zinc, antimony and so on. It is of great economic value. The main features are: metal luster, color, streak is deep, low hardness, good thermal conductivity, than the major. Another feature is that because sulfides are often associated with magma, it is very easy to oxidize under the surface supergene action. Except for pyrite (6 ~ 6.5 hardness), the hardness is very low. Such minerals pyrite, chalcopyrite, galena, FeS2 CuFeS2, PbS, Sb2S3, stibnite sphalerite molybdenite, cinnabar HgS MoS2.

- Q: What are the specifications for bricks?

- In a proper ratio of lime sand brick and quartz sand, sand or fine sand, the ground, Kazumi Wa, semi dry pressing and autoclaved curing and. The fly ash brick is made of fly ash as main raw material and mixed with cement material such as coal gangue, stone powder or clay. It is made up of batching, molding, drying and roasting. It can make full use of industrial waste residue and save fuel.

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: How to test the aluminium bricks of high alumina refractory bricks?

- Forming high alumina brick will be tested on some professional equipment, it is suggested that you can go to the professional testing department to know about it!

- Q: What kind of material is the general metal case?

- We usually discuss the electromagnetic radiation of computer enclosures, mainly RF radiation, followed by MF leakage.Switch signal of RF radiation from computer high-speed leakage, such as one of the energy radiation is CPU frequency, graphics, display output line, keyboard, is the source of the operating characteristics of the computer leaked out, is also the main part of computer security.For the absorption of radio frequency radiation, the best is the use of copper materials, the use of other metals can also, thickness enough on the line.The most vulgar description is that people can sit in the case is a good thing.

Send your message to us

High Alumina Brick - Standard and Refractory Bricks

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords