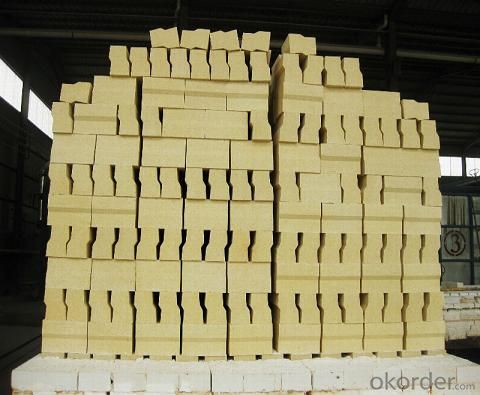

High Alumina Brick - 92% Alumina Brick for Refractory Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

92% high alumina brick

Size:0.5-95mm

anti-impact and wear resistance

Specification:>92%

Used in ceramics or pigments

High Alumina Brick, 92% Alumina Brick For Refractory Industry

92% alumina oxide ball (Moh's hardness>9)

High Alumina Brick, 92% Alumina Brick For Refractory Industry

Alumina ball for all sorts of ball mills, pearl mills, sand mills for the superfine grindings and dispersions of products with special quality requirements ,such as: Zircon sand, Silicon dioxide, Calcite(GCC),Magnetic bands coatings for audio and video tapes, paint, pigment,coatings,Ceramic glaze, Titanium dioxide and so on.

High Alumina Brick, 92% Alumina Brick For Refractory Industry

Main Advantage:

—High strength, Excellent wear resistance, keep the material high degree of purity.

—High density, high grinding efficiency, shortens 50% grinding times.

—Very good roundness, very smooth and shiny surface, long times of use.

High Alumina Brick, 92% Alumina Brick For Refractory Industry

High Alumina Brick, 92% Alumina Brick For Refractory Industry

- Q: What is the difference between corundum and high alumina??

- The difference between them lies in the content of alumina and the alumina refractory products with alumina content higher than 48%The content of Al2O3 is higher than 90%, which is called corundum brick.

- Q: What is the price of the latest thermal insulation material?

- Also through online pre understand the products and prices, and now have large-scale manufacturers are generally opened on the cable business. Goods than three, manufacturers on-site inspection, confirm the quality of goods after considering cooperation.

- Q: Application characteristics of high alumina brick

- Reheating line change. If the firing temperature of high alumina brick products is enough and the firing time is enough, the volume is stable, the change of the reheating line is small; on the contrary, the residual shrinkage of clay brick products is caused by recrystallization.

- Q: What is the standard classification of high alumina bricks and high alumina bricks?

- Refractory brick is non-metallic materials can be classified according to a kind of inorganic material, high aluminum brick, clay brick, magnesia brick, corundum brick, mullite bricks, silicon carbide materials such as brick, high alumina brick is used as a relatively wide range of products in accordance with the refractory brick high alumina refractory materials by high aluminum brick is generally divided into Al2O3 content three: I - II - >75% Al2O3 content; the content of Al2O3 is 60 ~ 75%; III - Al2O3 content from 48 to 60%.

- Q: How many cubic bricks does a high alumina brick have?

- It is related to the content of aluminum in high alumina bricks.

- Q: What materials are used for roof insulation?

- The other one is inorganic insulation materials, such as Portland, rare earth insulation, the thickness should be 5 cm or more, up to the high cost of auxiliary materials of construction, to reinforce, new inorganic insulation material, the material thickness, on the line of 2-3 cm, direct smear on the top of the house, without auxiliary material, than the price of wool, high aluminum silicate cotton.

- Q: Which is faster for heat transfer between corundum bricks and high alumina bricks?

- There must be a difference. They vary in color from the amount of aluminum, the weight, the temperature, and the color.

- Q: How to reduce porosity of high alumina brick

- In order to reduce the porosity of high alumina brick, the corresponding measures should be taken from the selection of raw materials, batching, mixing, molding and firing.

- Q: The difference between ordinary and diatomite brick refractory brick

- Refractory brick belongs to a large class, according to different materials used are divided into: high alumina brick, dolomite brick, magnesia chrome brick, magnesia spinel brick, phosphate brick, carborundum brick, brick, mullite bricks etc..

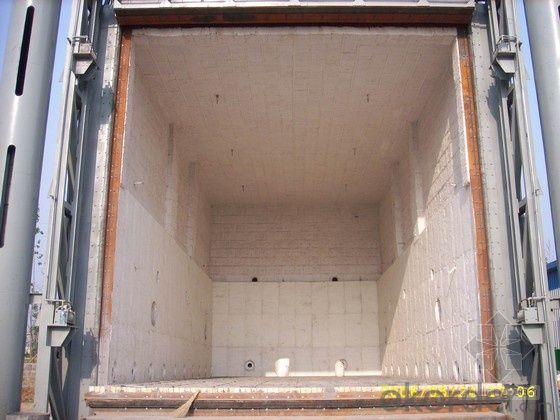

- Q: What are the requirements for refractory materials in heat treatment furnace?

- Refractoriness is the property of a refractory against high temperature, which means the temperature at which a refractory is softened to some extent after heating, but not its melting point. According to the degree of refractory, refractory materials can be divided into: General refractories, refractory degree is 1580 to 1770 DEG C; advanced refractories, refractory degree is 1770 to 2000 DEG C; special refractory material, refractory degree is greater than 2000 DEG C.

Send your message to us

High Alumina Brick - 92% Alumina Brick for Refractory Industry

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 11 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords