Heat and Sound Insulation Color Steel PU SandWich Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Sandwich panels are used in those applications where high structural rigidity and low weight is required. An evident example of use of sandwich panels is aircraft where mechanical performance and weight saving is essential. Other applications include packaging (e.g. fluted polypropylene boards of polypropylene honeycomb boards), transportation and automotive as well as building & construction.

Specifications

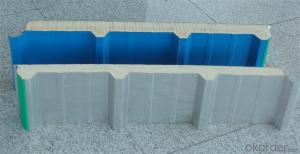

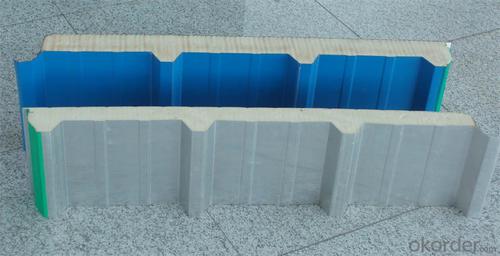

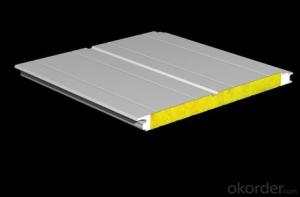

PU Color Steel SandWich Panel

1.Fireproof

2.Heat Insulating

3.Density:40kg/cbm

Product Description

1. Heat and sound insulation. Temperature suitable for PU ranges from -200 centigrade to 150 centigrade.

2. Good chemical resistance, waterproof, anti-corrosion, insect-free etc.

3. Advanced Tech: Automatic rolling machines make the whole process of manufacture effective.

4. Energy conservation, environmental protection, economical, heat insulting, good structure, easy-doing construction

5. Light weight enough to reduce building expense.

6. Time can be saved on a building project due to the simple installation

Size

Item Data

Effective Width: 1150MM/960MM/950MM

Length: Can be customized

Materials: foam board(EPS), Color steel sheet

Structure: Upper and lower layer: Color steel sheet

Middle: EPS foam board

Density of Core Material: 36-45KG/m3

Thickness of color steel sheet: 0.3-0.8MM

Colors: Blue, white or according to your requirements

- Q: What is the thickness of the steel sheets?

- The thickness of the steel sheets can vary depending on the specific application and requirements. Common thicknesses for steel sheets range from 0.4 millimeters to several inches, with standard measurements including 0.5 mm, 1.0 mm, 1.5 mm, 2.0 mm, 2.5 mm, and so on. However, it is important to note that the thickness can be customized based on the intended use, such as for construction, manufacturing, or automotive purposes. Therefore, it is essential to consult the specifications or inquire with the manufacturer or supplier to determine the exact thickness of the steel sheets in question.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets possess exceptional weather resistance properties, renowned for their ability to withstand diverse weather conditions like rain, snow, and wind. This is attributed to their composition and the protective coatings they bear. Notably, steel sheets can endure extreme temperatures, both hot and cold, without experiencing any considerable deterioration or harm. Furthermore, their resistance to corrosion is highly pronounced, rendering them an optimal choice for outdoor applications and locations exposed to high humidity or saltwater. Consequently, the weather resistance possessed by steel sheets guarantees their long-lasting and robust nature, establishing them as a dependable option for a wide range of construction and industrial purposes.

- Q: What is the process of etching or engraving on steel sheets?

- The process of etching or engraving on steel sheets involves using various techniques to create designs or patterns on the surface of the steel. Typically, a design is either etched or engraved onto a protective coating applied on the steel sheet using chemicals, tools, or lasers. The protective coating is then removed, revealing the etched or engraved design on the steel surface. This process is commonly used in industries such as manufacturing, jewelry making, and metal art.

- Q: What is the difference between a matte and glossy steel sheet?

- The main difference between a matte and glossy steel sheet lies in their surface finish. A matte steel sheet has a dull, non-reflective surface that diffuses light, resulting in a more muted appearance. On the other hand, a glossy steel sheet has a smooth, reflective surface that reflects light, giving it a shiny and polished look.

- Q: What are the different methods of joining steel sheets together?

- There exists a variety of techniques for connecting steel sheets, each possessing unique benefits and applications. Some commonly employed techniques include: 1. Welding: Utilized extensively, welding effectively joins steel sheets by melting their edges and fusing them together through the application of heat. Different welding processes, including arc welding, gas welding, and spot welding, are available, each tailored to specific applications. 2. Riveting: Riveting, a mechanical method, utilizes metal fasteners called rivets to connect steel sheets. Rivets are inserted into pre-drilled holes in the sheets and secured in place by hammering or pressing. Riveting is renowned for producing robust and long-lasting joints. 3. Bolting: Bolting employs bolts and nuts to hold steel sheets together. Holes are drilled through the sheets, and bolts are inserted from one side, with nuts tightened on the other side to secure the joint. Bolting offers the advantages of being quick, easy to assemble, and allows for disassembly if necessary. 4. Adhesive bonding: Adhesive bonding employs specialized adhesives to join steel sheets. The adhesive is applied between the surfaces to be joined and forms a strong bond as it cures. This method is commonly employed in industries where welding may distort the materials or is not feasible due to the specific materials involved. 5. Mechanical fastening: Mechanical fasteners such as screws, self-tapping screws, or nails may be used to join steel sheets. These fasteners create a sturdy connection by penetrating the sheets and holding them in place. Mechanical fastening is relatively swift and does not necessitate any specialized equipment. 6. Clinching: Clinching is a cold forming process that connects steel sheets by deforming the material without the use of external heat. It involves pressing the sheets together and forming a mechanical interlock. Clinching is frequently employed in the automotive industry due to its high-speed production capabilities and joint strength. Each technique possesses its own advantages based on factors such as joint strength, ease of assembly, cost, and specific application requirements. The selection of a joining technique depends on the intended purpose of the joint, material properties, and the environmental conditions to which the joint will be exposed.

- Q: What are the advantages of using steel sheets in automotive manufacturing?

- Automotive manufacturing can benefit from the utilization of steel sheets for several reasons. Firstly, the high strength and durability of steel sheets make them well-suited for enduring the demanding conditions and stresses encountered by vehicles on the road. This remarkable strength ensures the production of safer and more dependable vehicles, as steel sheets provide a robust protective structure capable of absorbing impact energy in the event of a collision. Secondly, steel sheets possess exceptional formability, allowing them to be easily shaped and molded into various intricate designs required for automotive components. This adaptability permits the creation of precise and elaborate parts, guaranteeing a flawless fit and optimal performance. Moreover, steel sheets exhibit commendable resistance to corrosion, a crucial characteristic for automotive applications. Vehicles encounter a variety of environmental factors such as moisture, salt, and chemicals, which can lead to rust and corrosion. However, by utilizing steel sheets with protective coatings, manufacturers can ensure that their vehicles have an extended lifespan and preserve their aesthetic appeal. Additionally, steel sheets present themselves as a readily available and cost-effective alternative to other materials used in automotive manufacturing. Steel is extensively utilized in numerous industries, which has resulted in the establishment of a well-developed supply chain for steel sheets. This accessibility not only guarantees a consistent supply for automotive manufacturers but also assists in maintaining manageable production costs. Lastly, steel sheets possess excellent thermal conductivity, which is essential for effective heat dissipation in automotive applications. Vehicles generate a substantial amount of heat, particularly in the engine and exhaust systems. Steel sheets aid in efficiently transferring and dissipating this heat, preventing overheating and ensuring optimal performance. In conclusion, the advantages of utilizing steel sheets in automotive manufacturing encompass high strength and durability, exceptional formability, commendable resistance to corrosion, cost-effectiveness, and efficient heat dissipation. These factors make steel sheets the preferred choice for the production of safe, reliable, and long-lasting vehicles.

- Q: Are steel sheets suitable for outdoor furniture?

- Yes, steel sheets are suitable for outdoor furniture. Steel is known for its durability and resistance to weather elements such as rain, sunlight, and temperature fluctuations. It can withstand outdoor conditions without rusting or deteriorating easily, making it a suitable choice for outdoor furniture.

- Q: Are steel sheets suitable for outdoor sculptures or artwork?

- Yes, steel sheets are suitable for outdoor sculptures or artwork. Steel is a durable and weather-resistant material that can withstand various outdoor elements such as rain, wind, and sunlight. It allows artists to create intricate and large-scale structures that can be placed outdoors without the risk of damage or deterioration. Additionally, steel sheets can be easily manipulated and welded, providing artists with the freedom to shape and form their artistic vision.

- Q: Are steel sheets suitable for food processing applications?

- No, steel sheets are not suitable for food processing applications.

- Q: What are the different types of steel sheet finishes for marine applications?

- Some of the different types of steel sheet finishes for marine applications include hot-dip galvanized, stainless steel, and epoxy coatings.

Send your message to us

Heat and Sound Insulation Color Steel PU SandWich Panel

- Loading Port:

- Guangzhou

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords