HAI YAN Variable-frequency drive-lx2000-01

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

AC line harmonics

It is also possible to replace the standard diode-bridge rectifier with a bi-directional IGBT switching device bridge mirroring the standard inverter which uses IGBT switching device output to the motor. Such rectifiers are referred to by various designations including active infeed converter (AIC), active rectifier, IGBT supply unit (ISU), active front end (AFE), or four-quadrant operation. With PWM control and a suitable input reactor, an AFE's AC line current waveform can be nearly sinusoidal. AFE inherently regenerates energy in four-quadrant mode from the DC side to the AC grid. Thus, no braking resistor is needed, and the efficiency of the drive is improved if the drive is frequently required to brake the motor.

Two other harmonics mitigation techniques exploit use of passive or active filters connected to a common bus with at least one VFD branch load on the bus. Passive filters involve the design of one or more low-pass LC filter traps, each trap being tuned as required to a harmonic frequency (5th, 7th, 11th, 13th, . . . kq+/-1, where k=integer, q=pulse number of converter).

It is very common practice for power companies or their customers to impose harmonic distortion limits based on IEC or IEEE standards. For example, IEEE Standard 519 limits at the customer's connection point call for the maximum individual frequency voltage harmonic to be no more than 3% of the fundamental and call for the voltage total harmonic distortion (THD) to be no more than 5% for a general AC power supply system.

Long-lead effects

The carrier-frequency pulsed output voltage of a PWM VFD causes rapid rise times in these pulses, the transmission line effects of which must be considered. Since the transmission-line impedance of the cable and motor are different, pulses tend to reflect back from the motor terminals into the cable. The resulting voltages can produce overvoltages equal to twice the DC bus voltage or up to 3.1 times the rated line voltage for long cable runs, putting high stress on the cable and motor windings, and eventual insulation failure. Note that standards for three-phase motors rated 230 V or less adequately protect against such long-lead overvoltages. On 460 V or 575 V systems and inverters with 3rd-generation 0.1-microsecond-rise-time IGBTs, the maximum recommended cable distance between VFD and motor is about 50 m or 150 feet. Solutions to overvoltages caused by long lead lengths include minimizing cable distance, lowering carrier frequency, installing dV/dt filters, using inverter-duty-rated motors (that are rated 600 V to withstand pulse trains with rise time less than or equal to 0.1 microsecond, of 1,600 V peak magnitude), and installing LCR low-pass sine wave filters. Regarding lowering of carrier frequency, note that audible noise is noticeably increased for carrier frequencies less than about 6 kHz and is most noticeable at about 3 kHz. Note also that selection of optimum PWM carrier frequency for AC drives involves balancing noise, heat, motor insulation stress, common-mode voltage-induced motor bearing current damage, smooth motor operation, and other factors. Further harmonics attenuation can be obtained by using an LCR low-pass sine wave filter or dV/dt filter.

Dynamic braking

See also: Dynamic braking and Regenerative braking

Torque generated by the drive causes the induction motor to run at synchronous speed less the slip. If the load drives the motor faster than synchronous speed, the motor acts as a generator, converting mechanical power back to electrical power. This power is returned to the drive's DC link element (capacitor or reactor). A DC-link-connected electronic power switch or braking DC chopper controls dissipation of this power as heat in a set of resistors. Cooling fans may be used to prevent resistor overheating.

Dynamic braking wastes braking energy by transforming it to heat. By contrast, regenerative drives recover braking energy by injecting this energy into the AC line. The capital cost of regenerative drives is, however, relatively high.

Regenerative drives

Line regenerative variable frequency drives, showing capacitors (top cylinders) and inductors attached, which filter the regenerated power.

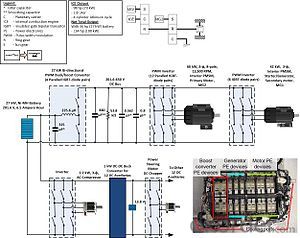

Simplified Drive Schematic for a Popular EHV

Regenerative AC drives have the capacity to recover the braking energy of a load moving faster than the designated motor speed (an overhauling load) and return it to the power system.

Cycloconverter, Scherbius, matrix, CSI, and LCI drives inherently allow return of energy from the load to the line, while voltage-source inverters require an additional converter to return energy to the supply.

Regeneration is useful in VFDs only where the value of the recovered energy is large compared to the extra cost of a regenerative system, and if the system requires frequent braking and starting. Regenerative VFDs are widely used where speed control of overhauling loads is required.

Some examples:

Conveyor belt drives for manufacturing, which stop every few minutes. While stopped, parts are assembled correctly; once that is done, the belt moves on.

A crane, where the hoist motor stops and reverses frequently, and braking is required to slow the load during lowering.

Plug-in and hybrid electric vehicles of all types

- Q: If humidity of a spacecraft is too high, how can it affect a crew and its equipment? what if it was too low?my sister did not get to go on her field trip but they gave her the worksheet this is the only question she cant answer please help!

- Humidity must be controlled on spacecraft. If the humidity is too high, then cold parts of the ship will experience condensation. If the condensation occurs on electrical equipment, there could be a short circuit. If the humidity is too low, then the astronauts will get dry skin and be uncomfortable. But it is probably better to err on the low side.

- Q: i know that megger is used in marine.but how its been used and please give me other megger application in detailedthanks for answer

- In electrical testing we megger equipment. A ac voltage 600 volts is induced one a piece of electrical equipment like a transformer and the impedance is measured. The megger measured AC resistance/impedance vs normal dc resistance that volt meter measure. The higher voltage gave a more accurate measure of impedance. Equipment with defective insulation, would have a lower impedance.

- Q: I just moved into a house a week ago and for the past couple of days weird things have been happening. The night before last my tv in my bedroom changed channel by itself and also I had a playstation remote sitting on top of my playstation and that fell on its own. Last night I was laying in bed and my door opened by itself and I am 100% sure that it was shut all the way. And again in the middle of the night it changed channel. I'm starting to get scared because all of this happens when my boyfriend is at work and its just me and my two boys. Is my house haunted, and what can I do?Btw my house is probably 100 years old.

- First lets look at the debunking side, some electrical equipment can have the same frequency, therefore operating that other item can change the channel, unless a neighbor lives near by and he is operation his TV and through the windows your TV changes. Since you just recently moved, things will seem different, and did you put the play station flat, or because it wasn't stored correctly it fell. New home and doors may operate differently, especially since it's an old house, the door will usually swing one way, and some just takes a small amont of wind, air vent whatever. First check out all these things and see if you can ascertain if any reason why this is happening and if you squarely cannot debink it, then perhaps it is paranormal.I am a big believer in the spiritual world since I have seen so many of them, and made communications.in the fifty years of experiences one one was a bad spirit.so I don't worry when I find out a home is haunted, I have actually made friends with one because she is that nice to me. So perhaps it's a good spirit looking over you and does these things to allow you to know it's there.

- Q: every electrical equipment is rated in VA or KW(motor) why transmission line rated in Volts though it carry power.

- Because voltage is the only thing that remains fairly constant. Even though industry and residential pull off that transmission line, the voltage is and Hertz is maintained for the sake of equipment that depends on a constant voltage. The current in the line fluctuates highly , depending on how many people are drawing on it at any instant

- Q: I accidentally connected the negative and positive terminals of my battery with a wrench, I have checked all the fuses and none look to be blown. What else should I be looking for?

- need more info, always include make and model and year, and we can tel lyou where the fusable link is. but usually its a thick place close to the battery terminals on the positive side. its like a larger size of the main wires that feed solenoids etc. good luck

- Q: I will be traveling to India in the next month. I have my laptop, camera and other electrical equipments which will need to be charged. I have heard that the voltage in India is 220 V and not 110 V. All my appliances work at 110 V, how do I make it work in India?

- Buy okorder

- Q: I want to wire all my regular recepticles with #10 wire which I know I can use 30 amp breakers with. Does anyone carry 30 amp 120 volt recepticles or can I use the 20 amp recepticles? I can't get anyone at Home Depot in the electrical department to answer the phone. Best answer with a link to this item (if it exists) gets ten points. Please not a lowes link. I don't care to do business with them as I can never get anyone in my local store (Nederland, TX) to help me, while Home Depot has bent over backwards and done cartwheels to help me. Thanks.

- You want a NEMA 5-30R receptacle but they're hard to find because virtually no one uses them. You occasionally see one on an RV. These receptacles aren't compatible with normal 15- and 20-amp plugs, so I'm not seeing what you're trying to accomplish. I'd just run more 20-amp circuits if you really need a lot of power.

- Q: I am about to finish my BS in Electrical Engineering and was considering getting a MS in EE but considering how the economoy is and the fact that the Bureau of Labor Statistics say it should grow slower than average. This being said what do you guys think is the most prudent thing to do in my case. Go for an MS Engineering Degree or start out with another degree maybe in healthcare.

- As per research, the job growth of electrical engineers will largely occur in engineering firms, government agencies, industrial sectors, and more. These engineers will also experience tremendous job growth in computer systems design, because these industries are focusing on manufacturing portable computing device. The rapid pace of technological invention will drive huge demand for electrical engineers in the research sector as well. So, those who're thinking of pursuing electrical and electronic engineering will experience favourable employment opportunities in the years to come.

- Q: I have been warned that some electrical equipment could possibly be damaged by chinese electrical systems.what voltage system does china use. is the supply unreliable and prone to spikes or surges etc.

- China uses 220V. If you don't trust the system, then get a surge protector + a converter and use them together with your equipment. I don't know what country you're from, so I can't suggest a converter because different countries use different voltages. When I was in China, I never experienced any problems with the electrical system and I had my cellphone, video camera, digital camera, hair straightener, etc. plugged in frequently. If you're in the big city, I doubt anything bad would happen.

- Q: (without using any connection wires)? I frequently need to plug existing electrical equipment in places where there is no power outlet I have to use clumsy long tailed electrical extension plug that hinders free movement ? Short of using a battery in the equipment how to connect the power junction points (earth live neutral to an existing electrical power outlet using nothing but air in between)?

- Resurrect Nicola Tesla, he could do it for you. Anything short of that, will necessitate your going over his patents for wireless transmission of electrical energy, and do it yourself. It can be done, but no one will admit it, nor tell you how. I doubt your utility company will like the idea either, as direct application of his design my end up spinning their meters backward and they'll end up owing you money.

Send your message to us

HAI YAN Variable-frequency drive-lx2000-01

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 10 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches