GRP FRP Pipes Sea Water Pipe Series DN 80

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features & Benefits of GRP FRP pipe sea water pipe series

Corrosion-resistant

•Long, effective service-life materials

•No need for linings, coatings, cathodic protection, wraps or other forms of corrosion protection

•Low maintenance costs

•Hydraulic characteristics essentially constant over time

Light weight

(1/4 weight of ductile iron; 1/10 weight of concrete)

•Low transport costs (nestable)

•Eliminates need for expensive pipe handling equipment

Long standard lengths

(6, 12 metres)

•Fewer joints reduce installation time

•More pipe per transport vehicle means lower delivery costs

Extremely smooth bore

•Low friction loss means less pumping energy needed and lower operating costs

•Minimum slime build-up can help lower cleaning costs

Precision sealability

With elastomeric rubber rings

•Tight, efficient joints designed for bell & spigot to eliminate infiltration and ex-filtration

•Ease of joining, reducing installation time

• Accommodates small changes in line direction without fittings or differential settlement

Flexible manufacturing

•Custom diameters can be process manufactured to provide maximum flow volumes with ease of installation for rehabilitation

lining projects

High technology pipe design

•Lower wave celerity than other piping materials can mean less cost when designing for surge and water hammer pressures

High technology pipe manufacturing system producing pipe that complies to stringent performance standards (AWWA, ASTM, DIN, EN, etc.)

•High and consistent product quality worldwide which ensures reliable product performance

Control Testing of GRP pipe sea water pipe series

Raw Materials

Raw materials are delivered with vendor certification demonstrating their compliance with Zhongfu Lianzhong quality requirements. In addition, all raw materials are sample tested prior to their use. These tests ensure that the pipe materials comply with the specifications as stated

Physical Properties

The manufactured pipe’s hoop and axial load capacities are verified on a routine basis. In addition, pipe construction and composition are confirmed.

Finished Pipe

All pipes are subjected to the following control checks:

• Visual inspection

• Barcol hardness

• Wall thickness

• Section length

• Diameter

• Hydrostatic leak tightness test to 1.5 rated pressure (only PN6 and above)

On a sampling basis, the following control checks are performed:

• Pipe stiffness

• Deflection without damage or structural failure

• Axial and circumferential tensile load capacity

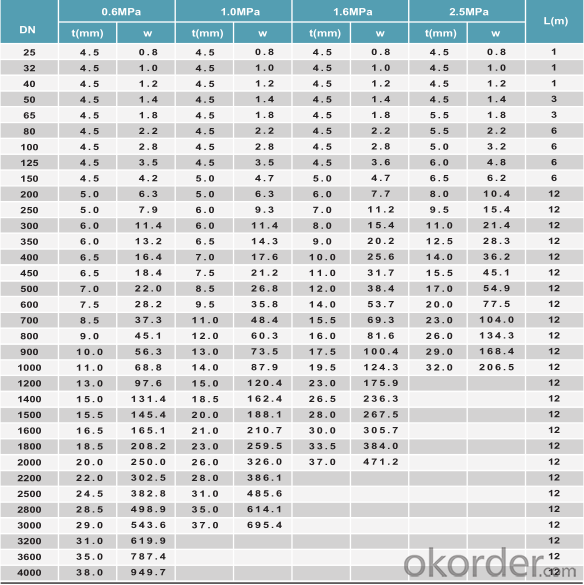

Thickness and Weight of Standard Pipes based on Internal Pressure of GRP pipe sea water pipe series

1. Internal liner (thickness 1.0 – 2.0 mm)

In tables bellow thickness include 1.5mm of liner and minimum pipe Stiffness 1250 Pa

2. Mechanical resistant layer in glass filament winding (based on internal pressure)

3. Top coat (0.2 – 0.3mm) . In tables bellow thickness include 0.2mm of top coat

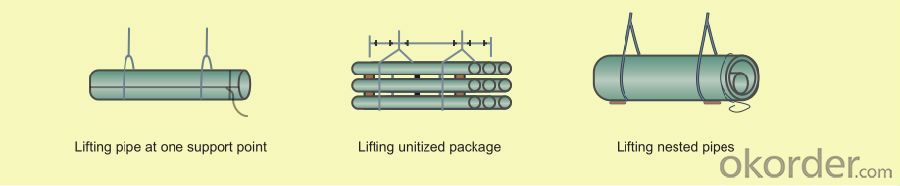

Unloading,Handling,Transportation and Storage of GRP pipe sea water pipe series

Unloading and Handling Pipes

Unloading the pipe is the responsibility of the customer. Be sure to maintain control of the pipe during unloading. Guide ropes attached to pipes or packages will enable easy manual control when lifting and handling. Do not drop, impact, or bump the pipe, particularly at pipe ends.

If at any time during handling or installation of the pipe, any damage such as a gouge, crack or facture occurs, the pipe should be repaired before the section is installed.

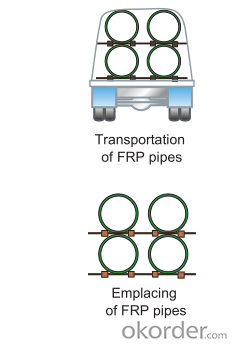

Transporting Pipes

Strap pipe to the vehicle over the support points using pliable straps or rope. Never use steel cables or chains without adequate padding to protect the pipe from abrasion. Bulges, flat areas or other abrupt changes of curvature are not permitted. Transport of pipes outside of these limitations may result in damage to the pipes.

Site Pipe Storage

It is generally advantageous to store pipe on flat timber to facilitate placement and removal of lifting slings

around the pipe.

When storing pipe directly on the ground, be sure that the area is relatively flat and free of rocks and other

potentially damaging debris. Placing the pipe on mounds of backfill material has been found to be an effective

way of site storing the pipe. All pipes should be chocked to prevent rolling in high winds.

FAQ of GRP pipe sea water pipe series

Q1: What’s the performance standards?

Lianzhong pipe is designed to meet all of these ASTM , AWWA, BS, DIN standards.

Q2: What’s the qualification testing for the products?

Lianzhong pipe has been rigorously tested to verify conformance to the ASTM D3262, ASTM D3517, AWWA C950 and DIN 16868 requirements

Q3: How long can I receive my goods?

A: Usually, we will deliver products within 20 days after the contract is signed. Delivery time is negotiable when necessary.

- Q: Winding method of glass fibre reinforced plastic pipeline anticorrosive glass fiber cloth

- 1) first, apply the release agent on the molding surface of the glass lined sand pipe mold (or a transparent cellophane on the outer surface of the mold);2) after sufficient drying, the magnesium oxychloride cement with initiator (or curing agent), accelerant and other additives is evenly coated on the molding surface of the die;3) then put a good glass cloth on the glass lined sand pipe;4) then apply the magnesium oxychloride cement on the paved glass cloth and take care to remove the bubbles.5) with good magnesium oxychloride cement paste then with cut glass cloth;6) repeat this operation until the GRP sand pipe reaches the design and gauge thickness.

- Q: FRP pipe and 0.7 thick galvanized pipe which cost is low?

- The best material in glass steel mould rubber production 20 years, customers in all aspects

- Q: What are the standards for FRP pipes?

- In order to comprehensively check the installation quality of the pipeline, it is necessary to carry out a comprehensive examination according to the test methods stipulated in the code for construction and acceptance of water supply and drainage pipeline works and to carry out the water pressure test. Permissible water seepage can be carried out according to the standard of FRP pipe.

- Q: The outer thermal protection layer of the pipeline is made of GFRP. Which guy knows the construction method?

- Usually with aluminum or iron sheet, with glass or steel, or the first time, I'm afraid the toughness is not enough.

- Q: Glass tube has different diameters with different prices. Who can elaborate?

- According to the standard requirements, DN25-DN2500 pipes can be produced. The pressure levels are gravity flow, 0.6MPa, 1.0MPa, 1.6MPa

- Q: Galvanized steel sheet and inorganic glass fibre reinforced plastic pipe are calculated according to this norm or norm

- 1, the quota valuation, wind pipe materials, such as the "loss" of galvanized steel has been included in the quota content, including the lap and material loss, making the wind pipe.2, when calculating the actual material, it can be calculated according to the calculation area of the air pipe * (1+ fixed loss) = the actual amount of material used.

- Q: What is the difference between glass tube, sand pipe and glass tube?

- If the thickness of the pipe can meet the requirements of pressure, but can not meet the stiffness requirement, will choose to increase the thickness of sand to meet the stiffness (of course can not directly increase the sand thickness to meet the requirement of stiffness, but the cost is too high). Sand sandwiched glass fiber reinforced plastic pipes only have more than one sand sandwiched with glass fiber reinforced plastic pipes, and sand layer can be understood to replace glass fiber with quartz sand. The sand pipe with the same thickness is compared with the glass fiber reinforced plastic pipe, but the sand holding pipe is cheap, but the strength is poor; and the glass steel pipe is opposite.

- Q: There is a gap between the new glass fiber reinforced plastic pipe and its through wall. How can the plug be prevented from leaking through the cracks around the pipe?

- Through wall holes, made of other materials, wall fittings, ship wall fittings and glass fibre reinforced plastic pipes, flanges or other forms of connections are used, which may be referred to the application of the components of the ship piping;

- Q: What are the posts of glass fiber reinforced plastic sand pipe and the corresponding occupational hazards and protection?

- Glass reinforced plastic underground sand pipe has long service life without operation and maintenance, which is the biggest advantage of this product. Since pipe jacking is an underground concealed project, its service life is undoubtedly the very important consideration of decision-makers. The service life of glass fiber reinforced plastic sand pipe jacking is more than 50 years, which is incomparable to the products such as steel pipe, concrete pipe and so on.

- Q: A basic overview of FRP pipes

- FRP pipes are used in petroleum, chemical and drainage industries. Glass fiber reinforced plastic pipeline production in China has developed rapidly, and the quantity has been increasing year by year, and the scope of application and departments are becoming wider and wider.

Send your message to us

GRP FRP Pipes Sea Water Pipe Series DN 80

- Loading Port:

- Lianyungang

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords