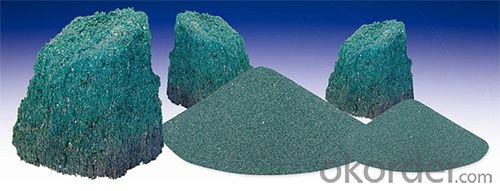

High Purity Green Silicon Carbide - Low Price Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Details: | 1) 25kg woven bag,40 woven bags/jumbo bag. 2) 25kg woven bag,40 woven bags/pallet 3) 25kg paper bag,40 paper bags/pallet 4) 25kg paper bag,40 paper bags/paper box |

| Delivery Detail: | 10DAYS AFTER CONFIRMATION ORDER |

Specifications

F220 High purity SiC

Professional manufacturer

Passed REACH ,ISO-9001:2008

We provide the best quality C in china with high tech testing instrument gurantee the quality.

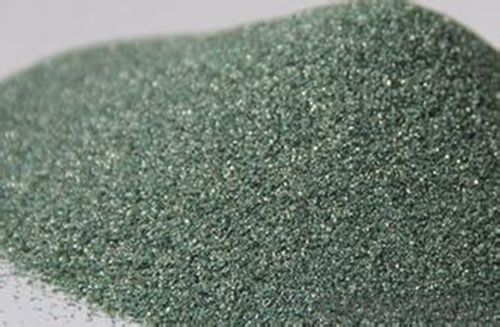

Grinding Black Silicon Carbide

Black silicon carbide is produced at high temperature in an electric resistance type furnace with quarts sand and petroleum coke as its main raw materials. It is used for making bonded and coated abrasive tools, grinding metal and non-metal materials of lower tensile strength, such as gray cast iron yellow bronze,aluminum, stone, leather, rubber, etc.

Chemical Compsition (%)

Grit | Sic | F.C. | Fe2O3 |

F12-F90 | ≥98.50 | <0.20< span=""> | ≤0.60 |

F100-F150 | ≥98.00 | <0.30< span=""> | ≤0.80 |

F180-F220 | ≥97.00 | <0.30< span=""> | ≤1.20 |

F230-F400 | ≥96.00 | <0.40< span=""> | ≤1.20 |

F500-F800 | ≥95.00 | <0.40< span=""> | ≤1.20 |

F1000-F1200 | ≥93.00 | <0.50< span=""> | ≤1.20 |

P12-P90 | ≥98.50 | <0.20< span=""> | ≤0.60 |

P100-P150 | ≥98.00 | <0.30< span=""> | ≤0.80 |

P180-P220 | ≥97.00 | <0.30< span=""> | ≤1.20 |

P230-P500 | ≥96.00 | <0.40< span=""> | ≤1.20 |

P600-P1500 | ≥95.00 | <0.40< span=""> | ≤1.20 |

P2000-P2500 | ≥93.00 | <0.50< span=""> | ≤1.20 |

Physical Index

Grits | Bulk Density | High Density | Grits | Bulk Density | High Density |

F16 ~ F24 | 1.42~1.50 | ≥1.50 | F100 | 1.36~1.45 | ≥1.45 |

F30 ~ F40 | 1.42~1.50 | ≥1.50 | F120 | 1.34~1.43 | ≥1.43 |

F46 ~ F54 | 1.43~1.51 | ≥1.51 | F150 | 1.32~1.41 | ≥1.41 |

F60 ~ F70 | 1.40~1.48 | ≥1.48 | F180 | 1.31~1.40 | ≥1.40 |

F80 | 1.38~1.46 | ≥1.46 | F220 | 1.31~1.40 | ≥1.40 |

F90 | 1.38~1.45 | ≥1.45 |

Size Available

F12-F1200,P12-P2500

0-1mm,1-3mm,6/10, 10/18, ,200mesh,325mesh

Other special spec. could be supplied as required.

- Q: Which manufacturers have the best fire-proof materials with light weight?

- It now appears that asbestos is the best among the most common fireproof materials. But asbestos also has great harm, especially to lung. Shanghai Xinlong Fireproofing Material Co., Ltd. and Hubei Boyue Lightweight Material Co., Ltd. were established in 2009. The company is located in Wuhan Biological New Town and covers an area of ??30 acres. The company is a specialized enterprise which is mainly engaged in the research and development, production, sale and construction of lightweight partition board, lightweight fireproof wall panel and lightweight wall panel. The two companies are both good.

- Q: What's the maximum temperature that the refractory ceramic fiber cloth can endure?

- It depends on the composition of the ceramic material. If its composition is alumina and it is used by civilians, its normal use temperature is 1200℃; if its composition is alumina but it is for millitary use, it can endure the highest temperature of 2200℃.

- Q: Who knows what kind of material the fire-proof plate use, and is it good?

- It is the decorative board made by adopting silicious material or calcareous material as the main raw material, and blending them with certain proportion of fibrous material, lightweight?aggregate, adhesive and chemical?additive before steam pressing. It is a kind of new material and more and more frequently used currently not only for it is fireproof. Construction of the fire-proof plate has higher requirements on the adhesive, and the price of the fire-proof plate with better quality is more expensive than that of the decoration panel. The thickness of the fire-proof plate is generally 0.8mm, 1mm, and 1.2mm. So it is the best material for making cupboards.

- Q: I want to know what is the slim in the refractory bricks

- Where are you from, I can introduce to you

- Q: Which brand of AAA refractory is good?

- Rong Sheng Kerui quality refractory Zhengyuan Shenzhou Saatchi these brands are very good, with high refractoriness, durability and with a good cost performance. Get the majority of customers' recognition.

- Q: What is the material of fire resistant glass reinforced plastics grating?

- What is the material of fire resistant glass reinforced plastics grating?

- Q: What are refractory materials?

- Refractories can be divided to two categories based on the shape and three categories according to the chemical nature of acidity, neutralily and alkalinity. Alkaline refractory materials are magnesia-carbon brick, magnesia chrome brick, calcium magnesium brick and magnesia-chrome bricks. Neutural refractory mateial are high alumina brick, corundum brick and clay brick. Case-hardened refractory materials are castable, ramming mass, gunning mix, coated mix, dry vibration material, etc.

- Q: What are fire?ratings of wall thermal insulation material?

- 1.thermal insulation material with grade A combustion performance: YT inorganic active insulation material for wall thermal,rock wool, glass wool, foam glass, foamed ceramics, foam cement, hole-closed perlite, etc. 2.thermal insulation material with grade B combustion performance: Extruded polystyrene board(XPS)after special treatment/polyurethane(PU) after special treatment, phenolic aldehyde,gelatine powder polyphenyl granule, etc. 3.thermal insulation material with grade B2 combustion performance: Molding polystyrene board(EPS), extruded polystyrene board(XPS), polyurethane(PU), polyethylene(PE), etc.

- Q: What are the requirements on fire resistance period of C-level fireproof glass?

- Class C: The fireproof glass which only meets demand of fire integrity. This glass has advantages of transmittance, fireproofing, smoke resistance and high intensity. It can be applied to fireproof glass partition walls, fire windows and with no requirements on outdoor curtain walls, etc. The fireproof glass can be classified as composite fireproof glass and single chip fire-proof glass in terms of structure. Class B: The fireproof glass which meets demands of fire integrity and thermal radiation intensity at the same time. This glass is mostly composite fireproof glass which has advantages of transmittance, fireproofing, and smoke resistance.

- Q: What is the biggest difference between refractory bricks and clay refractory bricks? Where can I find information on the refractory bricks?

- You can look up knowledge manual of refractory material to find phosphatic material, etc. Xinjiang refractory bricks, castable refractory, refractory material, silicious, corundum and alumina-magnesia: High alumina and clay refractory bricks can be divided into

Send your message to us

High Purity Green Silicon Carbide - Low Price Raw Materials for Refractory

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords