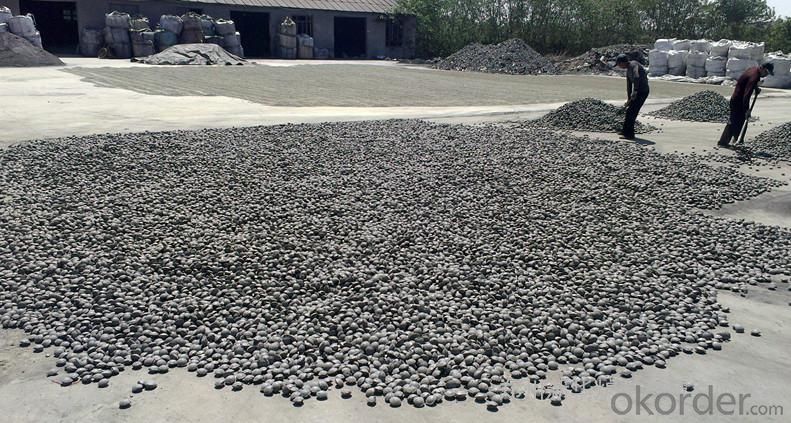

Green SIC Ball Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

green sic ball is a new type of composite deoxidizer for steel makingThe company produces green sic ball is a new type of composite deoxidizer , to instead of ferrosilicon, silicon carbide , carburant ,reduce the amount of deoxidizer and alloying process for smelting deoxy.

Application:

Improve steel quality , improve product quality , improve product new energy , and reduce the amount of alloy added to reduce the cost of steel making , increase economic.

Specifications:

type | Sic% | FREEC% | Si+SiO2% | Fe2O3% | MGO% | H2O% | size |

Lytz- Sic98.5 | ≥98.5 | ≤0.2 | ≤0.06 | <1.5 | 0-30mm | ||

Lytz- Sic98 | ≥98 | ≤0.3 | ≤0.8 | <1.5 | |||

Lytz- Sic97 | ≥97 | ≤0.3 | ≤1 | <1.5 | |||

Lytz- Sic95 | ≥95 | ≤0.4 | ≤1 | <1.5 | |||

Lytz- Sic90 | ≥90 | ≤0.6 | ≤1.2 | <1.5 | |||

Lytz- Sic85 | 85±3 | ≤1 | 8±3 | ≤1.5 | <1.5 | ||

Lytz-Sic75 | 75±3 | 2.5±1 | 17±2 | 3 | 0.10 | <1.5 | |

Lytz-Sic65 | 65±3 | 4.5±1 | 23±2 | 4 | 0.12 | <1.5 | |

Lytz-Sic55 | 55±3 | 4.8±1.5 | 28±3 | 5±2 | 0.16 | <1.5 |

- Q: Which industry does refractory belong to? Does it belong to construction industry?

- It belongs to material, and after all, more than 60% refractories are used in metallurgical industry. If you insist on classifying it, it belongs to supporting industry of metallurgical industry. Refractory industry itself is independent.

- Q: What are the fire resistance ratings of the glass partition?

- Hello, friend. The glass partition system is composed entirely of metal structures, glass, color plate and other materials which also has fire resistance capacity. When the inner structure of the system is steel structure, the fire resistance of which is 30 mins, 60mins or even longer.

- Q: What's the definition of fire endurance of the fire-resistant coating for steel structure?

- 1. Fire endurance. Conduct fire resistance test of any building component according to the standard time-temperature curve, and the time when it is subjected to the fire to the time when it loses support capability or fire insulation function or its integrality is destroyed is referred to fire endurance. 2. Steel has relatively low fire endurance which is usually 0.25h only, namely 15 minutes; 3. Of steel structure buildings, steel can be used as beams, pillars, etc. but its fire endurance is not enough (usually these components have higher requirement on fire endurance, and take pillar as an example, it is usually demanded that the fire endurance should be 2-3h), and under this condition, it needs to brush fire retardant coating so as to raise the fire endurance. As to the specific quantity or types of the fire retardant coating, it is decided upon the actual conditions. In short, the building material needs to meet the required fire endurance of the buildings.

- Q: What's the heat conductivity coefficient of fire-resistant material?

- The heat conductivity coefficient of fire resistant material is related to bulk density and mainly related to the internal structure. Different materials have different structure and thermal conductivity and temperature . Carbonaceous material can be used for heat dissipation and reach more than 15. For thermal insulation it can be 0.00.

- Q: What needs to be noted when choosing and using blast furnace fireproof materials? Who knows?

- there are different temperatures in various parts of the blast furnace, thus using different types of refractory.

- Q: What's the difference of fire-resistant material's density, specific gravity and bulk specific gravity?

- It usually used to test lightweight refractory. Density can be divided into apparent density (usually called as density) and true density: apparent density includes blow hole inside the sample; Unit weight is using quality to divide volume of sample and specific weight is used to represent liquid.

- Q: Is aluminium oxide refractory material?

- Calcination aluminium oxide is refractory material of fine performance made from pure aluminium oxide through high-temperature calcination. It can be made into coarse-grained material, fine-grained material, fine powder and micro powder, which can be made into pure jade burnt products. For example, corundum brick, lightweight corundum bricks. It can also be made into a variety of unburning products together with other materials, such as carbonaceous materials. For example, aluminum carbon and aluminium zirconium carbonaceous materials. As for the production of unshaped refractory material, there are more species. It can be corundum, rubing grain, corundum spinel and can also be added into other materials to improve specific performance. It isn't limited to high-alumina castable refractory and it can be castable refractory, ramming?mass, impressionable plastic material, gunning mix and refractory mortar.

- Q: Who knows the roofing fireproofing and waterproof material?

- If you should do home water proofing, I recommend the acrylate waterproof coating with high elasticity of Qinglong waterproof, because it has good aging resistance, extensibility, elasticity, binding property and film-forming property; waterproof layer is a closed system, the overall waterproof effects are very good, especially for the construction of heterotypic structure base and roofing, walls, toilet and bathroom, basement and other buildings waterproof and anti-seepage engineering in the conditions of non-permanent immersion;

- Q: What's the fire resistance rating of the exterior fire?retardant?coating?

- Current fireproofing material is mainly classified into five grades: A class: Incombustible building material which is almost incombustible. A1 class: It is noncombustible and cann't cause open fire. A2 class: It is noncombustible but needs to measure the smoke it will cause and that should be qualified. B1 class: Flame-retardant building materials: Good in fire retardation, it is non-combustible when meeting open fire in the air or under high temperature, and it is difficult for the fire to spread quickly. Besides, when the fire source is removed, combustion stops immediately. B2 class: Combustible building material: It has certain fire retardation. In the case of open fire in the air or at high temperature, it will immediately burst into flames, and easily lead to the spread of fire, such as the spread to wooden pillars, timber roof truss, timber beams, wood stairs, etc. B3 class: Flammable building material has no fire retardation effect at all. It is highly combustible with big fire risk. Besides, the classifications of fire resistance rating of building materials are different according to different standards: dDIN4102: A1, A2, B1, B2, B3; x0dEN13501-1: A1, A2, B, C, D, E, F. Hope it helps.

- Q: how does the fire endurance of first rate fire resistant window?

- the classes are different. class A window not less than 1.5 hours, and the time is short, class B window not less than 1 hours, with shorter time, Class C window not less than 0.5 hours.

Send your message to us

Green SIC Ball Raw Materials for Refractory

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords