Graphite Die Mold Inc Graphite Sintering Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

graphite part:ISO9001

high quality with best price

produce graphite mould as per drawing

supply graphite product stably

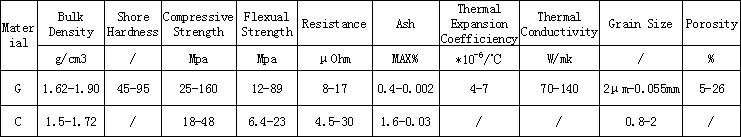

The physical and chemical properties of C and G material:

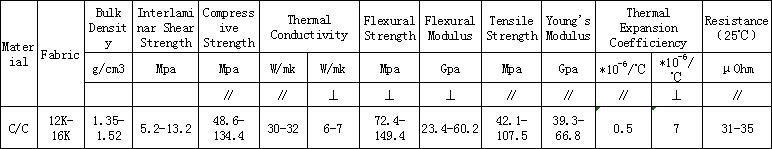

The physical and chemical properties of C/C material:

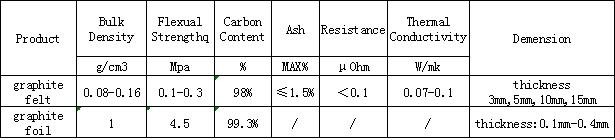

The physical and chemical properties of other material:

Products of carbon and graphite are widely used in such fields as industrial furnaces, mono-crystalline silicon machinery, mono-crystalline silicon machinery, electron, semi-conductor, metallurgy, oil, chemistry, textile, electrical machinery, electrical equipment, electrical furnace, traffic, communication industry, medicine, etc.

Providing graphite heating systems used in mono-crystalline silicon and multi-crystalline silicon industrial furnaces (such as heaters, thermal insulation material, insulation materials, etc.)

Providing graphite moulds, molds, graphite felt, graphite foil, graphite rod, graphite sheet, utensils, crucibles used in furnaces(such as graphite boats ,outer molds, mounting plates, etc.)

Providing graphite crucibles and utensils used for particular amorphous metal, rare metal, and non-ferrous metal and crystallizers for the growth of ferrous metal, etc.

Providing mechanical seal parts, graphite rings, graphite bearings, graphite leaf

Providing carbon felt, carbon cords, graphite power, graphite felt, and compound carbon felt of different specifications

- Q: What are the electrodes on the die?

- Graphite electrode has the advantages of easy processing, high metal removal rate and low graphite loss. Therefore, more and more die factories give up the use of copper electrode instead of graphite electrode.

- Q: How can the die steel be sharpened?

- Grinding method for white steel cutter of die:1, if you have edge, can use the fine flour water along the edge of the grinding stone;2, if not to use oilstone rough edged, dripping, and the vertical mill, namely the blade, which can then be used to drop down the edge grinding surface of fine aggregate.

- Q: How to make the graphite mould and how to form the graphite mould?

- Graphitized productsSuch products include graphitized electrodes, graphitized anodes, graphitized blocks, high-purity, high-strength, high-density graphite, etc..These products are made of petroleum coke or asphalt coke as the main raw material. At last, they are treated at high temperature over 200 degrees Celsius to convert amorphous carbon into graphite. Its characteristics, C > 99%, gray powder 0.5%, conductive and electrothermal good, good corrosion resistance; production process complex and long cycle, generally 40~60 days.

- Q: What are the specific categories of Shi Moru?

- Shi Moru's main component is graphite, because of its milky state, it is often referred to as graphite milk, Qingdao Huatai graphite professional graphite milk manufacturers, graphite milk mainly in the following two categories.

- Q: I do the mold, graphite is raw materials, production of products will have a lot of waste residue, in order to environmental protection, I would like to ask how to deal with it?

- Graphite is a good carburizing agent and can be sold to a foundry as an agent

- Q: Now the mould cavity EDM electrode material is the most widely used

- Copper and pure copper.In addition, larger cavity molding is often done with graphitePrecision machining is useful to tungsten, molybdenum, etc., but very few"

- Q: How do graphite blocks do mirror treatment?

- Graphite blocks are usually polished with Whetstone, sandpaper, and polishing paste. The polishing method is to use coarse aggregate the entire surface polished smooth, remove thick marks, scratches.

- Q: Where can I sell graphite mould?

- Mold is widely used in industrial production of basic process equipment, mold industry is the basic industry of the national economy. In modern industrial production, stamping, forging, die casting, extrusion, plastic injection or other processing methods widely used in product parts, and forming mold of supporting the blank forming product in accordance with the requirements of the parts. A variety of tools and products used in our daily life and production, to the machine base body shell, the first embryo to a small screws, buttons and various household appliances, all have a close relationship with the mold. The shape of the mold determines the shape of these products, and the quality and accuracy of the die determine the quality of these products. In recent years the rapid development of mold industry, graphite materials, new technology and the increasing of the impact of the mold factory mold market, becoming the first choice of graphite mold making materials with good physical and chemical properties.

- Q: How to use and manufacture graphite mould in hot pressing diamond tools?

- While in hot pressing, because of the sameWhen the temperature is heated and pressed, the temperature can be sintered as long as the bonding metal reaches the plastic body, so the temperature is low and the time is short. becauseThe compressive strength of diamond decreases with the increase of sintering temperature and time.

- Q: Graphite mold, graphite ring and other graphite products, how about anti oxidation coating?

- Therefore, the temperature resistance is more stable, brushing on graphite to form a dense coating, with rust prevention, corrosion resistance, high temperature resistance, oxidation resistance, wear-resistant and other characteristics.

1. Manufacturer Overview

| Location | Beijing,China (Mainland) |

| Year Established | 1998 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | 70.00% Domestic Market 10.00% Eastern Europe 10.00% Western Europe 5.00% North America 5.00% Southeast Asia |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | xingang |

| Export Percentage | 21% - 30% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 30,000-50,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Graphite Die Mold Inc Graphite Sintering Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Pieces pc

- Supply Capability:

- 1000 Pieces per Week pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches