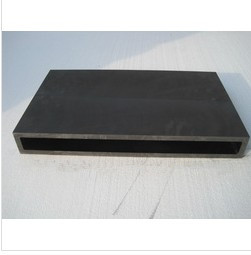

Graphite Mold Suppliers Horizontal Continuous Casting Flat Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 10,000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

- Application: Casting

- Technique: Die Molded

- Dimensions: Various of specification according to customers' requirement

- Bulk Density (g/cm³ ): ≥1.87g/cm³

- Porosity (%): 15%

- Compressive Strength: 65Mpa-85Mpa

- Composition: Carbon

Specifications

Graphite Mould1 high pure and density

2 mould for casting industry

3 high strength graphite

4 long using life

Graphite Mould

Feature:

1. Thermal stability: According to the quench acute thermal using conditions of graphite crucible, we will specially design the production procedure, so as to ensure the reliability of product quality.

2. Corrosion resistance: Even and fine basic design will delay the erosion of crucible.

3. Impact resistance: Graphite crucible can bear high thermal impact, so any process can be carried out.

4. Acid resistance: The adding of special materials will greatly improve the quality of crucible, especially its index of acid resistance., and will prolong the service life of graphite crucible.

5. High heat Conduction: High content of fixed carbon ensures the good heat conduction, shorten the time of dissolution, and remarkably reduce the energy consumption.

6. Control of metal pollution: The component of material under strict control will ensure that graphite crucible will not pollute the metals when dissolving.

7. Quality stability: The process technology of forming under high pressure and quality guarantee system will fully ensure the stability of quality

Graphite molds Materials index:

1.Content: 99.99%

2.Density: 1.87g/cm³

3.Compressive strength: 65mPa

4.Shore hardness: 55

5.Porosity: 15%

Application:

1. Brass continuous casting mould

2. Red copper continuous casting mould

3. Continuous casting mould for jewelry of gold, silver, platinum, etc.

4. Steel and stainless steel continuous casting mould.

By the shape of the cast product, it is divided into round bar mould, hollow tube mould, and shaped mould.

- Q: Can graphite be used as a gear?

- No, it's low hardness,Generally do not use graphite as gear

- Q: Why should graphite mould be used for oxyacetylene ablation test?

- Graphite mold refers to the graphite material mold, mold is used in industrial production is very extensive basic process equipment, mold industry is the basic industry of the national economy.

- Q: What are the specific categories of Shi Moru?

- With good high temperature lubrication, protect the mold, reduce wear and tear. Excellent high temperature coating, 600-1200 degrees does not fall off and does not burn, the protection of wire material is not oxidized, easy to save, no spoilage. Used in drawing lubricant. Such as tungsten wire, molybdenum wire, rhenium wire, thorium wire and other lubricants.

- Q: Graphite mold maintenance

- Maintenance in production:1. when the mold is used, the guide post and guide sleeve should be lubricated regularly2., in the production of regular corresponding parts and edges of the mold should be repeated lubrication or stamping oil3. in addition to other items prohibited double punching, stamping materials, lubricants should be far away from the work area.4. edges of the iron powder can not delay too much, should be timely source of retention of materials and regular cleaning of scrap, after the end of the production of the mold to conduct a comprehensive inspection, comprehensive cleaning, guarantee the cleanliness of the mold.

- Q: What are the suppliers of mobile 3D glass hot bending graphite die?

- I suggest to take some measures, you can download a Android optimization master to use, can be appropriate to reduce the load, mobile phone, Android optimization master power saving management functions can be seen clearly, with open content consumption program, can be selectively closed now don't need it in the power consumption of the program, to reduce mobile phone load

- Q: How do graphite blocks do mirror treatment?

- Then polished diamond paste (grain size W5) polished, and finally use (W3.5) of diamond polishing paste polished to the mirror surface.

- Q: Graphite mold glass mold stamping?

- Plastic mold in the production process, the product appears trapped gas, usually the mold does not set the exhaust structure, the need to open the exhaust tank.

- Q: How to use and manufacture graphite mould in hot pressing diamond tools?

- For the same diamond tools, the hot press is lower than the cold pressing temperature, and the time is short.

- Q: What are the differences between domestic and imported graphite? Who can tell me? What are they used in?

- The import of fine graphite particles, the surface of the products out of the relatively smooth, no large grains of sand hole, suitable for precision EDM, imported graphite can do bone and groove of 0.2-0.3, after the discharge is not easy.

- Q: Graphite mold, graphite ring and other graphite products, how about anti oxidation coating?

- Therefore, the temperature resistance is more stable, brushing on graphite to form a dense coating, with rust prevention, corrosion resistance, high temperature resistance, oxidation resistance, wear-resistant and other characteristics.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2010 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | 20.00% South America 20.00% Eastern Europe 20.00% South Asia 20.00% Domestic Market |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | QINGDAO |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | AVERAGE |

Send your message to us

Graphite Mold Suppliers Horizontal Continuous Casting Flat Mould

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 Piece pc

- Supply Capability:

- 10,000 Pieces per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches