Graphite Electrode Price Per Ton for Arc Furnace by Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

Graphite electrode is made from the domestic first petroleum coke and widely used in the electric arc furnaces for production of alloy steels, metal and other nonmetallic materials, etc.

The graphite electrodes include regular power, high power, super high power, ultra high power and square electrode.

The range of diameters covers from 200mm to 700mm.

Our products own the following characteristics: low electric resistance, good electric and thermal conductivity, high oxidation resistance, greater resistance to thermal and mechanicalshock, high mechanical strength, high machining accuracy.

Graphite Electrodes Features:

RP HP UHP Graphite Electrode

1.Dia:40-600mm or1.6"-24"

2.Length:250-2400mm or10"-96"

3.Nipples:3TPI,4TPI

4.ISO9001:2008

Graphite Electrodes Application:

An increasing proportion of global steel is made using electric arc furnaces, and the electric arc furnace itself is getting more efficient and making more steel per tonne of electrode

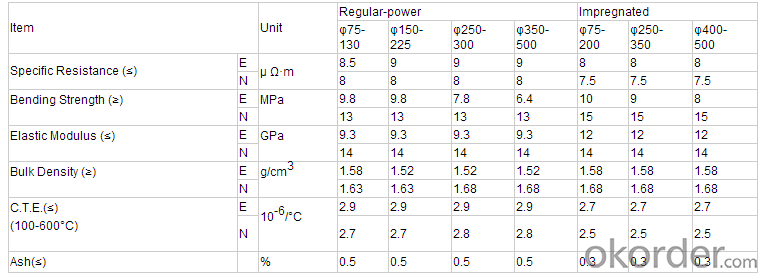

Graphite Electrodes Specifications

Do you know our material of the graphite electrode?

The regular power graphite electrode is made from petroleum coke with a little pitch, which meets

the state standards YB/T4088-2000

The high power graphite electrode is made form 70% petroleum coke and 30% imported needle

coke, which meets the state standards YB/T4089-2000

The ultra high power graphite electrode is made form 100% imported needle coke, which meets

the state standards YB/T 4090-200

Technical data:

Note: The consumption of Electric Arc Furnace(EAF) is about 3-5kg per ton steel. The Ladle Furnace(LF) is about 1kg per ton steel. The converter with Ladle Furnace(LF) is about 0.5kg per ton steel. All the information is for your reference. There are many factors can influence the consumption, such as the kinds of steel, conduction time, process production and so on. So if you have any question, please don’t hesitate to contact us.

FAQs:

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: How to improve the efficiency of graphite electrode milling, please tell me

- There are many factors that determine the need to continue producing graphite electrodes, so high-speed machining has become a key manufacturing process in the die manufacturing industry. Compared with the time required for the milling of graphite electrodes, the processing of high rigidity hard steel still takes longer. When milling dies, cavities, and complex 3D surfaces on hard steel, radial runout errors and tool deviations often result in fracture of the tool. When the tool is broken, it will not only stop the continuous processing of the steel, but also affect the quality of the product, which will lead to the scrap of the parts and the waste of the material.

- Q: The future of graphene

- Field of semiconductor materials. Graphene is considered to be an ideal material for replacing silicon. A large number of powerful enterprises have developed graphene semiconductor devices. The Han Guocheng Institute has developed a highly stable n type graphene semiconductor that can be exposed to air for a long time. Graphene silicon optoelectronic hybrid chip developed by Columbia University has broad application prospects in optical interconnection and low power photonic integrated circuit. IBM researchers have developed graphene field effect transistors with cutoff frequencies of up to 100GHz, with frequency performance far superior to the cut-off frequency of the most advanced silicon transistors of the same gate length.

- Q: The original battery is not necessary to form the electrode potential? Why can we use graphite as electrode only? No potential difference.

- A galvanic cell is a device that converts chemical energy into electrical energy. Electron transfer not by oxidizing and reducing agents to complete the effective collision between, but the reducing agent loss electron oxidation reaction occurs in the anode, the electron transport to the anode through the external circuit, the oxidant to the anode electron reduction reaction, so as to complete the transfer of reductant and oxidant electrons.

- Q: MITSUBISHI machine graphite electrode processing, how does not accumulate carbon?

- The impact of carbon on the car is quite large, first of all, to reduce the power of the engine, that is, to make the power output uneven and gradually attenuated, in other words, more and more lack of force. Two is to increase fuel consumption, increase your financial burden.

- Q: What is the application of wire cutting with graphite electrode?

- With the development of science and technology, the machine manufacturing technology has undergone profound changes. Due to the social demand for diversification of products is more intense, more varieties, small batch production increasing proportion in WEDM by traditional processing equipment has been difficult to adapt to the processing of high efficiency, high quality, diversified requirements, CNC technology should be used

- Q: How should carbon deposits be treated?

- In this way, can keep the engine seal, to prevent oil because the gap is too large and rampant, buried carbon curse generation "".

- Q: The graphite electrode made by the machining center adopts cooling method, which is water cooled, oil cooled and blow cold. Which is good?

- Use oil cold. Air cooling will cause graphite dust flying, on the one hand, toxic, on the one hand there are security risks (caused by circuit short circuit). Water cooling is virtually out of use, taking into account the maintenance and maintenance of the CNC.

- Q: Why is graphite a negative pole and copper is an anode?

- Electrolysis (Electrolysis) is the current through the electrolyte solution or molten electrolyte (also called electrolyte), caused by the redox reaction in the cathode and the anode, the electrochemical cell can occur when an external DC voltage in the electrolysis process.

- Q: I remember the more lively metal, the electron?

- C metal is copper, because a dilute sulfuric acid into the H2 precipitation, then definitely not copper. And the inactive first precipitate

- Q: How do graphitized electrodes differentiate between high power and low power?

- In electrolysis industry, using graphite anode plate as the anode has a history of more than 100 years, the metal anode is in recent decades, the research and application of metal anode in China late last century, only in 70s the technology related to the research and experiment of metal anode, anode on electrolysis industry, mainly through the silver (2%) (0.5%): low silver lead silver alloy, lead and silver tin antimony alloy, lead calcium alloy and lead silver alloy adding nucleating agents and several stages.

Send your message to us

Graphite Electrode Price Per Ton for Arc Furnace by Manufacturer

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords