Grade JIS SGHC-SGH540 Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

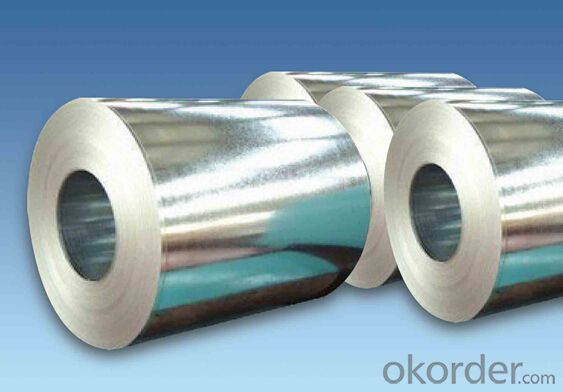

Grade JIS SGHC-SGH540 Galvanized Steel Coil

Specification of Grade JIS SGHC-SGH540Galvanized Steel Coil

1. Galvanized Steel Coil

(1) Width: 600-1570mm

(2) Thickness: 0.13-5.0mm

(3) Grade: JIS G3302-SGCC-SGC570, SGCH (full hard-G550), SGHC-SGH540

EN10346-DX51D+Z, DX53D+Z, S250GD-S550GD

STM A653-CS-B, SS255-SS550

(4) Zinc Coating: Z40g/m2~Z500g/m2 (both side total coating thickness)

2. Galvalume Steel Coil

(1) Width: 600~1500mm

(2) Thickness: 0.15~2.30mm

(3) Grade: JIS G3321-SGLCC, SGLC400-570, (G550)

EN10346-DX51D+AZ, DX53D+AZ, S250-S550

ASTM A792M CS-B, SS255-SS550

(4) AZ Coating: AZ50~AZ185g/m2

3. Prepainted Galvanized Steel Coil (PPGI)

(1) Width: 600~1250mm

(2) Thickness: 0.19~1.50mm

(3) Grade: JIS G3312-CGCC, CGC340-570, (G550)

ASTM A755M CS-B, SS255-SS550

(4) Zinc Coating: Z40g/m2~Z500g/m2 (both side total coating thickness)

4. Prepainted Galvanized Steel Coil (PPGL)

(1) Width: 600~1250mm

(2) Thickness: 0.20~1.50mm

(3) Grade: JIS G3322-CGLCC, CGLC340-570, (G550)

ASTM A755M CS-B, SS255-SS550

(4) AZ Coating: AZ50~AZ185g/m2 (both side total coating thickness)

5. Cold Rolled Steel Coil (Soft) (for further information, pls click the product name)

(1) Width: 600~1570mm

(2) Thickness: 0.13~2.50mm

(3) Grade: JIS G3141-SPCC-SD, SPCD-SD, SPEC-SD

JIS G3135-SPFC 340/390/440

EN10130-DC01, DC03, DC04

SAE1006, SAE1008

ASTM A424-TypeⅡ

6. Cold Rolled Steel Coil (Full Hard) (for further information, pls click the product name)

(1) Width: 600~1570mm

(2) Thickness: 0.13~2.50mm

(3) Grade: JIS G3141-SPCC-1B, SPCC-1D

7. Hot Rolled Steel Coil

(1) Width: 1000~1524mm

(2) Thickness: 1.20~16.5mm, other thickness can be negotiation

(3) Grade: JIS G3101-SS400, JIS G3132-SPHT1/2/3, ASTM A36, Q195, Q235 etc.

Company Introduction of the Grade JIS SGHC-SGH540 Galvanized Steel Coil

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

Packaging & Delivery Grade JIS SGHC-SGH540 Galvanized Steel Coil

Packaging Detail | Sea worthy packing /as per customer's packing instruction |

Delivery Detail | 15 ~ 40 days after receiving the deposit |

Products Show:

FAQ:

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust

|

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the main applications of special steel in the pharmaceutical industry?

- Special steel is widely used in the pharmaceutical industry for various applications. One of the main applications is in the manufacturing of equipment and machinery used for drug production, such as mixing tanks, reactors, and centrifuges. Special steel is preferred in these applications due to its excellent corrosion resistance, high strength, and durability, ensuring the integrity of the pharmaceutical processes and preventing contamination. Additionally, special steel is also used for constructing cleanroom furniture and fixtures, which require high cleanliness standards to maintain the sterility of pharmaceutical environments. Overall, special steel plays a crucial role in ensuring the quality, safety, and efficiency of pharmaceutical manufacturing processes.

- Q: Can special steel be used for medical applications?

- Yes, special steel can be used for medical applications. It is often used for surgical instruments, implants, and medical devices due to its high strength, corrosion resistance, and biocompatibility.

- Q: How is stainless steel used in food processing?

- Stainless steel is widely used in food processing due to its exceptional properties such as corrosion resistance, durability, and hygiene. It is used to manufacture various equipment like storage tanks, mixing vessels, piping systems, and food preparation surfaces. Stainless steel's non-reactive nature prevents contamination and ensures food safety, while its smooth surface allows for easy cleaning and maintenance. Additionally, its strength and heat resistance make it suitable for high-temperature processes in food processing plants.

- Q: How is nitriding steel used in the production of tools and dies?

- Nitriding steel is used in the production of tools and dies to enhance their hardness, wear resistance, and overall performance. The process of nitriding involves introducing nitrogen to the surface of the steel, forming a hard nitride layer that significantly improves the tool's durability and lifespan. This treatment allows the tools and dies to withstand high temperatures, resist corrosion, and maintain their sharpness, making them more efficient and cost-effective in various industrial applications.

- Q: How does special steel perform in terms of corrosion resistance?

- Special steel has excellent corrosion resistance due to its high content of alloying elements, such as chromium, nickel, and molybdenum. These elements form a protective layer on the surface of the steel, preventing corrosive substances from reaching the underlying metal. Additionally, special steel can be further enhanced with surface treatments or coatings to enhance its resistance to corrosion in harsh environments.

- Q: How does special steel perform in high-temperature environments?

- Special steel is specifically designed to perform well in high-temperature environments. It has excellent heat resistance, retaining its strength and hardness even at elevated temperatures. Special steel also exhibits good oxidation and corrosion resistance, reducing the risk of degradation or failure in high-temperature conditions. Overall, special steel is a reliable and durable material choice for applications requiring performance in high-temperature environments.

- Q: Can special steel be used in the railway industry?

- Yes, special steel can be and is commonly used in the railway industry. Special steel alloys such as manganese steel, stainless steel, and wear-resistant steel are often utilized in the manufacturing of railway tracks, wheels, axles, and other components. These special steel materials offer enhanced strength, durability, and resistance to corrosion and wear, making them ideal for withstanding the heavy loads, frequent use, and harsh environmental conditions experienced in the railway industry.

- Q: What is the role of chromium in special steel?

- The unique properties and characteristics of chromium are crucial in special steel. It is added primarily to steel alloys to enhance their corrosion resistance, durability, and strength. One significant contribution of chromium is its ability to form a passive oxide layer called chromium oxide on the steel's surface. This layer acts as a protective barrier, preventing corrosive elements like oxygen and moisture from reaching the steel. The corrosion resistance of chromium-containing steel makes it highly suitable for harsh environments, such as the marine or chemical industries. Moreover, chromium improves the mechanical properties of steel. It increases hardness, toughness, and wear resistance, making it valuable in manufacturing tools, machinery components, and other applications that require strength and durability. Chromium also helps retain sharpness and edge retention, making it ideal for high-quality knives and blades. Additionally, chromium is essential in heat-resistant steel alloys as it significantly improves the material's ability to withstand high temperatures without losing strength or shape. This makes it suitable for applications in turbine blades, exhaust systems, and aerospace components. In conclusion, chromium plays a vital role in special steel by enhancing corrosion resistance, improving mechanical properties, and enabling high-temperature resistance. These properties make chromium-containing steel alloys highly valuable and versatile in various industries and applications.

- Q: Can special steel be used for structural applications?

- Yes, special steel can be used for structural applications. Special steel refers to a wide range of steel alloys that are specifically designed to possess enhanced mechanical properties, such as increased strength, durability, and corrosion resistance. These qualities make special steel suitable for various structural applications, including buildings, bridges, pipelines, and heavy machinery.

- Q: What are the applications of special steel in the agriculture sector?

- Special steel has various applications in the agriculture sector due to its exceptional properties such as durability, corrosion resistance, and strength. It is used in the manufacturing of farm equipment and machinery like tractors, plows, harrows, and combine harvesters. Special steel is also utilized in the construction of storage silos, irrigation systems, and animal housing structures. Additionally, it is employed in the production of cutting tools and blades for efficient crop harvesting and maintenance.

Send your message to us

Grade JIS SGHC-SGH540 Galvanized Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords