Grade A36 SS400 Hot Rolled Steel Coil _HR Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

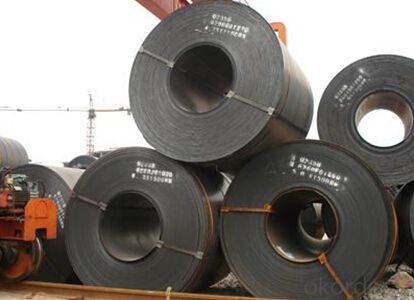

Grade A36 SS400 Hot Rolled Steel Coil _HR Coil for Construction

Specification

Product | Hot Rolled Steel Coil |

Place of origin | Tianjin, China |

MOQ | 25 tons |

Thickness | 1.0mm-80mm |

Width | 600mm-3000mm |

Length | In coil, 3000-15000mm |

Application | Construction of vessels, containers, buildings, |

roads, railways, other infrastructure, appliances, | |

and so on. | |

Standard | AISI, ASTM, BS, DIN, JIS, GB, etc |

Grade | A572,A573,A633,A678,A709,A710,G3101,G3136 |

Type | Steel Coil |

Surfacing | Vanished, painted, oiled or as request |

Technology | Hot Rolled |

Payment Terms | L/C,T/T, Western Union, Money Gram |

Product Ability | 5000 tons per month |

Delivery | Within 15-30 days upon receipt of L/C or deposits |

Packing | Standard seaworthy export packing or as the request of customers |

Name | Hot Rolled Steel Coil |

Standard | GB/ASTM/SAE/AISI/DIN/JIS/EN/BS |

Surface Treatment: | Black/Peeling/Polished/Machined |

Delivery Condition: | Hot Rolled or Forged/Peeled or Black Surface |

Test | SGS/UT 100% Elements Testing |

Certificate: | ISO/Mill Certificate |

Service: | 24 hours online service / |

more than 20 years trading and manufacture | |

Quality Assurance: | the third party inspection, such as SGS, BV, TUV…etc. is acceptable |

Packaging Details: | Seaworthy Packaging or as per customer's packing instruction |

Chemical Composition

| Chemical Composition | ||||

C | Si | Mn | P | S | |

Q345B | ≤0.20 | ≤0.55 | 1.00-1.60 | ≤0.040 | ≤0.040 |

Q345C | ≤0.20 | ≤0.55 | 1.00-1.60 | ≤0.035 | ≤0.035 |

Q345D | ≤0.18 | ≤0.55 | 1.00-1.60 | ≤0.030 | ≤0.030 |

Company Information

CNBM International Corporation is the most import and export platform of CNBM group(China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

After-sale service | l CNBM provides the services and support you need for every step of our cooperation. We’re the business partners you can trust; you can relax and get on with doing business. |

l For any problem, please kindly contact us at any your convenient time, we’ll reply you in our first priority within 24 hours | |

Advantages | Industry experience over 20 years. |

Shipment of goods -More than 70 countries worldwide. | |

The most convenient transport and prompt delivery. | |

Competitive price with best service. | |

High technical production line with top quality products. | |

High reputation based on best quality products. |

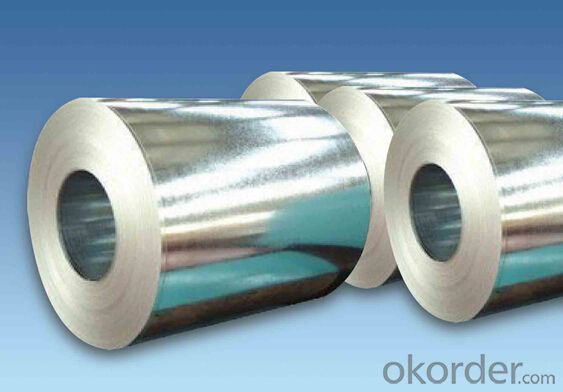

Product Show

FAQ

Are you a trading company or manufacturer? | Manufacturer |

What’s the MOQ? | 3 metric ton |

What’s your delivery time? | 15-35 days after downpayment received |

Do you Accept OEM service? | Yes |

what’s your delivery terms? | FOB/CFR/CIF |

What's the Payment Terms? | 30% as deposit,70% before shipment by T/T |

Western Union acceptable for small amount. | |

L/C acceptable for large amount. | |

Scrow ,Paybal,Alipay are also ok | |

Why choose us? | Chose happens because of quality, then price, We can give you both. |

Additionally, we can also offer professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposals. | |

What's your available port of Shipment? | Main Port, China |

What’s your featured services? | Our service formula: good quality+ good price+ good service=customer's trust |

Where are your Market? | Covering more than 160 countries in the world |

- Q: What are the different powder coating techniques used for special steel?

- There are several powder coating techniques used for special steel, including electrostatic spraying, fluidized bed coating, and electrostatic fluidized bed coating. These techniques involve applying a dry powder coating to the steel surface, which is then cured to form a durable and protective layer. Each technique has its own advantages and is used based on the specific requirements of the steel and the desired finish.

- Q: What are the advantages of using special steel in various industries?

- Special steel offers several advantages in various industries. Firstly, it has superior strength and durability, making it ideal for applications that require high performance and long-lasting materials. Secondly, special steel has excellent corrosion resistance, making it suitable for industries exposed to harsh environments, such as marine, oil and gas, and chemical industries. Additionally, special steel is highly versatile, allowing for customization and adaptability to specific requirements. It also provides excellent heat resistance, making it suitable for industries that involve high temperatures, such as aerospace and automotive sectors. Lastly, special steel offers great machinability, facilitating efficient and precise manufacturing processes. Overall, the use of special steel in various industries enhances performance, longevity, and cost-effectiveness.

- Q: What are the main applications of special steel in the packaging machinery?

- Special steel is widely used in packaging machinery for various applications, including the production of durable and corrosion-resistant parts such as blades, cutting tools, and machine components. The high strength and hardness of special steel allow for efficient and precise cutting, shaping, and sealing processes, ensuring the quality and reliability of packaging operations. Additionally, special steel's resistance to wear and tear enhances the longevity of packaging machinery, reducing maintenance costs and downtime.

- Q: What are the main factors affecting the heat resistance of special steel?

- The main factors affecting the heat resistance of special steel include its composition, microstructure, and processing techniques. The composition of the steel, particularly the presence of alloying elements such as chromium, nickel, and molybdenum, can greatly influence its ability to withstand high temperatures. Additionally, the microstructure of the steel, which is determined by factors like heat treatment and grain size, plays a significant role in its heat resistance. Finally, the processing techniques used during the manufacturing of the steel, such as forging or casting, can also impact its ability to withstand heat.

- Q: How does special steel contribute to the mining industry?

- Special steel plays a crucial role in the mining industry by providing the necessary strength, durability, and resistance to extreme conditions required for various mining equipment and machinery. It is used in the manufacturing of drill bits, excavator buckets, conveyor systems, crushers, and other mining tools. Special steel's exceptional properties allow for increased efficiency, reduced downtime, and improved safety in mining operations, ultimately contributing to enhanced productivity and profitability in the industry.

- Q: What are the different forging techniques for special steel parts?

- To produce special steel parts, there are various forging techniques available, which depend on the desired shape, size, and properties of the final product. Some commonly used techniques for forging special steel parts include: 1. Utilizing open-die forging involves shaping the metal between flat dies or anvils. It is suitable for simpler shapes and provides flexibility in producing a wide range of sizes. 2. Closed-die forging, also known as impression-die forging, involves shaping the metal within a closed die that contains the desired shape and allows for higher precision. It is commonly used for producing complex and intricate shapes. 3. Upset forging involves compressing and shaping the metal by applying pressure to the ends of the workpiece. This technique is often used to create parts with increased diameter or reduced length, such as bolts and nails. 4. Ring rolling is a technique that shapes a cylindrical workpiece by applying pressure from rotating rolls. It is commonly used for producing seamless rings with enhanced strength and durability, for example, gears, bearings, and flanges. 5. Isothermal forging is performed by forging the metal at a constant temperature, usually within a specially designed furnace. This technique allows for precise control over the metallurgical properties of the final product, resulting in improved mechanical properties and reduced residual stress. 6. Precision forging, also known as near-net-shape forging, uses specially designed dies to produce parts with minimal finishing operations. It is commonly used for complex shapes and high-volume production, ensuring cost-effectiveness and dimensional accuracy. 7. Press forging involves shaping the metal by applying pressure through a mechanical or hydraulic press. It allows for precise control over the forging process and is often used for producing high-strength, large-sized components. Each of these forging techniques offers unique advantages and is suitable for different applications. The appropriate selection of the forging technique for special steel parts depends on factors such as the desired shape, size, strength, and cost-effectiveness of the final product.

- Q: How does special steel perform in cryogenic applications?

- Special steel is renowned for its exceptional performance in cryogenic applications, characterized by extremely low temperatures that fall below -150 degrees Celsius (-238 degrees Fahrenheit). Unlike regular steel, which tends to become brittle and weaker in such conditions, special steel, also referred to as cryogenic steel or low-temperature steel, is specifically engineered to withstand these extreme cold temperatures. One of the key advantages of special steel lies in its ability to maintain its mechanical properties even at cryogenic temperatures. It retains its strength, toughness, and ductility, enabling it to endure the stresses and strains imposed on it in cryogenic environments. As a result, special steel finds application in various fields, including aerospace, energy, and healthcare, where it is used in cryogenic storage tanks, pipelines, and equipment. Another significant feature of special steel is its excellent resistance to brittle fracture at low temperatures. This is of utmost importance since brittle fractures occur when materials become excessively brittle and fail under stress. The distinct composition and processing methods employed in special steel help prevent such fractures, ensuring the integrity and safety of components within cryogenic systems. Furthermore, special steel possesses a low coefficient of thermal expansion, meaning it undergoes minimal dimensional changes when exposed to temperature fluctuations. This characteristic proves highly advantageous in cryogenic applications as it preserves the stability and reliability of equipment and structures. Additionally, special steel exhibits commendable corrosion resistance, which is vital in cryogenic environments where the presence of moisture and certain chemicals can accelerate corrosion processes. By resisting corrosion, special steel enhances the longevity and durability of components, thereby reducing maintenance and replacement costs. In conclusion, special steel is the preferred choice for cryogenic applications due to its ability to maintain mechanical properties, resist brittle fracture, display low thermal expansion, and exhibit corrosion resistance. These properties render it a dependable and efficient material for use in cryogenic systems, providing the necessary strength and durability even under extremely low-temperature conditions.

- Q: What are the different heat treatment processes used in special steel production?

- Some of the different heat treatment processes used in special steel production include annealing, tempering, quenching, and case hardening.

- Q: What are the specific requirements for special steel used in the aerospace fastener industry?

- To ensure the safety, reliability, and performance of aircraft components, the aerospace fastener industry demands special steel that meets specific criteria. These requirements include the following: 1. Remarkable strength: The special steel used in aerospace fasteners must possess exceptional strength to withstand the extreme forces and stresses experienced during flight. This is crucial for maintaining the structural integrity of aircraft components. 2. Resistance to corrosion: Aerospace fasteners are constantly exposed to various environmental conditions, including moisture, high temperatures, and chemicals. Therefore, the steel used must have excellent corrosion resistance properties to prevent degradation and maintain the longevity of the fasteners. 3. Exceptional fatigue resistance: Due to repeated loading and unloading cycles throughout the lifespan of aircraft components, the special steel used in aerospace fasteners must exhibit exceptional fatigue resistance. This ensures that the fasteners can endure cyclic loading without fracturing or experiencing any structural failures. 4. Ability to withstand temperature variations: Aerospace fasteners are subject to extreme temperature changes, ranging from sub-zero temperatures at high altitudes to elevated temperatures near engines. The steel used should possess excellent temperature resistance to maintain its mechanical properties under these conditions. 5. Lightweight nature: In the aerospace industry, weight reduction plays a crucial role in improving fuel efficiency and increasing the payload capacity of aircraft. Therefore, special steel used in aerospace fasteners should be lightweight without compromising on strength and other necessary properties. 6. Non-magnetic features: Certain aerospace applications require non-magnetic fasteners to prevent interference with sensitive electronic equipment, such as avionics and navigation systems. Consequently, the special steel used in such cases must exhibit non-magnetic characteristics. 7. Adherence to industry standards: Special steel used in the aerospace fastener industry must meet the stringent standards and specifications established by regulatory bodies like the International Organization for Standardization (ISO) and the National Aerospace and Defense Contractors Accreditation Program (NADCAP). Complying with these standards ensures the quality and reliability of the fasteners. Overall, meeting the specific requirements for special steel used in the aerospace fastener industry is paramount to ensuring the safety and performance of aircraft components. These requirements encompass high strength, corrosion resistance, fatigue resistance, temperature resistance, lightweight properties, non-magnetic characteristics, and compliance with industry standards.

- Q: What are the different production methods for special steel?

- There are several different production methods for special steel, each with its own unique advantages and characteristics. Some of the most common methods include: 1. Electric Arc Furnace (EAF): This method involves melting scrap steel in an electric arc furnace, where an electric current generates intense heat to melt the materials. EAF is popular for its flexibility, as it can produce a wide range of steel grades and alloys. 2. Basic Oxygen Furnace (BOF): In this process, molten iron from a blast furnace is combined with scrap steel and oxygen to remove impurities and adjust the carbon content. BOF is known for its high production capacity and ability to produce large quantities of steel. 3. Vacuum Induction Melting (VIM): VIM is a method used to produce high-quality and high-purity steel. It involves melting the raw materials in a vacuum environment to prevent contamination and achieve precise control over the alloy composition. 4. Continuous Casting: This method involves pouring molten steel into a water-cooled mold, which continuously produces solidified steel slabs, blooms, or billets. Continuous casting is known for its efficiency and ability to produce consistent and defect-free steel products. 5. Powder Metallurgy: This technique involves compacting and sintering metal powders to produce steel with specific properties. Powder metallurgy allows for the production of complex shapes, improved mechanical properties, and the incorporation of alloying elements that are challenging to achieve through traditional methods. 6. Additive Manufacturing (AM): Also known as 3D printing, AM is a relatively new method for producing special steel. It involves layer-by-layer deposition of metal powders, which are then fused together using heat or a laser. AM offers great design freedom, the ability to produce complex geometries, and the potential for customized steel parts. Each production method has its own advantages and limitations, and the choice depends on factors such as the desired steel properties, production volume, cost considerations, and the specific requirements of the end-use application.

Send your message to us

Grade A36 SS400 Hot Rolled Steel Coil _HR Coil for Construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords