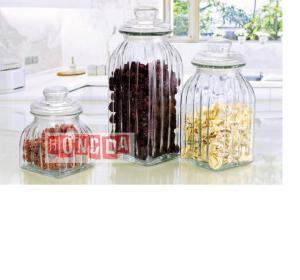

Glass Storage Jar 9720

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

This product uses the high quality material, suitable for various ingredients, such as dried fruit, wine. The bottle cap using food grade plug, health and environmental protection. Elegant, more capacity available, can also be drilled with water tap

(Filler belonging to display products, not in the sales range)

9720 Size:22x22x31cm Volume:7500ml

9720(4#) Size:20x20x25.5cm Volume:4000ml

9720(3#) Size:18x18x22.5cm Volume:3000ml

- Q: Ceramic pots are sprayed glaze, or the whole porcelain crystallization good?

- Ceramic crystallization: glass ceramic composite board is the product of "three in one" of glass, ceramic and stone craft. It combines the glass melting process, ceramic brick molding and crystallization sintering process, stone polishing, cutting process as a whole. In short, microcrystalline glass frit is special stalls shop in the special ceramic tile on the roller kiln sintering crystallization, after polishing and cutting timber.

- Q: What is the raw material of glass made of?

- The glass raw materials used for the natural ore, so the manufacture of glass, first of all to all kinds of ore crushing, processing into powder, then according to the glass component, made with the material into the glass melting furnace for melting glass forming liquid. Qualified glass flows through the feed tank and flows out of the feed port to form the stock. The temperature of the stock is 1150~1170 degrees centigrade and the alkali free glass is 1200~1220 degrees centigrade. The material shares every minute near '200 times cut into ball billet. The billet passes through the chute, the ball distributor and the ball plate, and then rolls into different funnels respectively, then falls into a groove formed by three rollers with the same rotating direction. When the ball is rotated on the roller and its surface tension, the ball glass is formed gradually. Its diameter is determined by the thickness, velocity, and shear velocity of the glass stream.

- Q: Is the production of glass materials as thin as possible? Why?

- Glass production is very strict to the granularity of various raw materials, and there is a usable range. Generally, refractory materials are finer, such as sand and feldspar. Some of them are coarse, such as dolomite and limestone. However, the most taboo is "superfine powder""!

- Q: How is glass made? I heard that sand is used, but what is the concrete principle?

- The main raw materials of flat glass are: silica sand (sandstone), sodium carbonate, feldspar, dolomite, limestone and mirabilite.

- Q: What are the raw materials of glass fiber reinforced plastic?

- The concept of composite material means that a material can not meet the use requirements, and needs to be composed of two or more than two materials together to form another material that can meet the requirements of people, that is composite material. For example, a single kind of glass fiber, although high in strength, but the fiber is loose, can only withstand tension, can not bear bending, shear and compressive stress, it is difficult to make a fixed geometry, is loose software.

- Q: What are the raw materials for making glass?

- The main raw material for making glass is sand, its main component is silica, which is commonly called quartz.

- Q: Is the price of glass raw material the biggest proportion of quartz?

- The main are: quartz sand. And soda ash.

- Q: What are the raw materials of water glass?

- Water glass production has two kinds of dry and wet method. Dry quartzite and soda ash as raw material, grinding mix, in the furnace to the temperature of 1300-1400 DEG C melting, press type reaction of solid water glass, dissolved in water and prepared liquid water glass

- Q: How is glass made? What material is it made of?.

- Bullet proof glass is made of glued laminated material, which is glued together with many pieces of glass or high strength organic board. Generally has the following three layers of structure:Bearing layer: firstly, the layer is broken by impact, and the glass with large thickness and high strength is used. It can destroy warhead or change warhead shape, and make it lose the ability to move forward.Transition layer: the general use of organic adhesive material, strong adhesion, light fastness, can absorb part of impact energy, change the direction of the bullet forward. A very strong and transparent chemical film is sandwiched between laminated glass. This can not only effectively prevent bullet shooting, but also has the properties of surge resistance, explosion resistance, shock resistance and no cracks after impact.Safety protection layer: this layer is made of high strength glass or high strength transparent organic material. It has better elasticity and toughness, can absorb most impact energy, and ensure that the bullet can not penetrate the layer

- Q: How do you pack something into (Qian Jin) plexiglass?

- The organic glass is divided into two layers to seal the flat object and then polish it.

Send your message to us

Glass Storage Jar 9720

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords