Glass Fiber Textiles Ceramic Fiber Insulation Wool Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Application: | Refractory | Grade: | ST (Standard) | Working Temperature: | 1050C |

| Place of Origin: | China (Mainland) | Brand Name: | SUNTHERM | Model Number: | SS wire reinforced |

| Certificate: | BV,SGS,CE,ROHS,ISO9001:2000 | Sample: | Available | MDS Availabel: | Yes |

Packaging & Delivery

| Packaging Detail: | Woven bag , carton or as your demand to custom |

| Delivery Detail: | Within 15 days after received the deposit. |

Specifications

Ceramic fiber textile

AL2O3:45%

Fiber diameter:3-5um

Temperature:1050C ISO9000 certificate

ceramic fiber rope includes square braided rope, round braided rope and twisted rope. All are made from high quality ceramic fiber material. The rope is reinforced with fiberglass filament, or alloy steel wire. Fiberglass filament reinforced rope can work in the temperature below 650C with electric insulating property, while alloy steel wire can work in the temperature 1100C with higher strength. Ceramic fiber textiles (cloth, tape and rope) contain a certain amount of binder material which is normally burned at lower temperature and does not affect the insulation property .The three different styles are designed to fit different application needs: twisted rope is a soft rope, while square and round braid are more dense and solid.

Product information

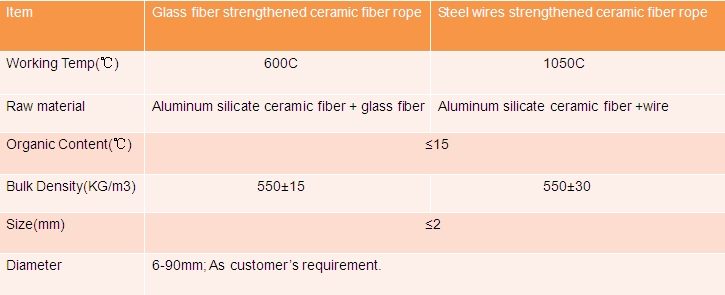

Item | Ceramic fiber rope |

Type | Glass fiber strengthened ceramic fiber rope Steel wires strengthen ceramic fiber rope |

Applications | • High temperature static seal e.g. door joint or gaskets for flanges • Fire protection e.g. fires proof curtain against welding spark. • The protection of cable, fuel tubes etc • Fireproof twine, wrap, cover etc • Pipe or round duct insulation lagging • Asbestos substitute |

Features | •Excellent high temperature stability • Excellent tensile strength • Excellent thermal electrical insulation • Excellent chemical stability resistance • Low thermal conductivity. |

Packing | In plastic bags, in cartons or according customers requirement. |

Payment Terms | L/C, D/A, D/P, T/T, Western Union, MoneyGram, Cash. |

Delivery Time | Within 15 days after received the deposit. |

Certificate | ISO9001-2000, ISO14001-2000, CE ,SASO,SGS . |

Technical data

- Q: Can glass fiber textiles be used in upholstery and home decor?

- Yes, glass fiber textiles can be used in upholstery and home decor. Glass fiber textiles, also known as fiberglass fabrics, are versatile and durable materials that can be used in various applications, including upholstery and home decor. These textiles are made by weaving glass fibers together, resulting in a strong and flexible fabric. In upholstery, glass fiber textiles can be used as a covering material for furniture such as chairs, sofas, and ottomans. They provide excellent strength and resistance to wear and tear, making them suitable for high-traffic areas. Additionally, glass fiber textiles are resistant to moisture, mildew, and pests, making them a practical choice for upholstery in homes. In home decor, glass fiber textiles can be used in various ways. They can be used as wall coverings, providing a unique and modern look to any room. Glass fiber textiles can also be used as curtains or drapes, adding a touch of elegance and texture to windows. Furthermore, these textiles can be used for decorative purposes such as creating intricate lampshades or decorative panels. Glass fiber textiles come in a variety of colors, patterns, and textures, offering endless possibilities for upholstery and home decor. They can be easily customized to match any interior design style, whether it's contemporary, traditional, or eclectic. Moreover, glass fiber textiles are easy to clean and maintain, making them a practical choice for households. Overall, glass fiber textiles are a versatile and durable option for upholstery and home decor. They offer strength, resistance to wear, and a wide range of design possibilities. Whether you are looking to upholster furniture or enhance the aesthetics of your home, glass fiber textiles can be a great choice.

- Q: Are glass fiber textiles resistant to tearing or ripping?

- Glass fiber textiles possess a remarkable ability to withstand tearing or ripping. Renowned for their exceptional strength and durability, glass fibers exhibit a high resistance to mechanical forces that could potentially cause tearing or ripping. The fibers utilized in glass fiber textiles are composed of slender strands of glass intricately interwoven to form a resilient and cohesive structure. Consequently, these textiles can endure substantial tensile forces without succumbing to tearing or ripping. Moreover, glass fiber textiles boast a remarkably high melting point, further fortifying their resistance to tearing or ripping even in extreme conditions. All in all, glass fiber textiles are a dependable and enduring choice for applications necessitating resistance to tearing or ripping.

- Q: What are the different coating options for glass fiber textiles?

- The selection of coating options for glass fiber textiles depends on the intended application and desired characteristics. There are several choices available: 1. Silicone Coating: These coatings, based on silicone, are well-liked for their remarkable heat resistance, flexibility, and water repellency. They give the glass fiber textiles a smooth and glossy finish, making them suitable for insulation, fireproofing, and protective clothing. 2. Polyurethane Coating: Polyurethane coatings provide enhanced abrasion resistance, durability, and chemical resistance. They act as a protective barrier against moisture, oils, and chemicals, making them perfect for industrial aprons, conveyor belts, and outdoor covers. 3. PTFE Coating: PTFE coatings are famous for their non-stick properties, high temperature resistance, and low friction. These coatings create a smooth and non-porous surface on the glass fiber textiles, making them suitable for release sheets, conveyor belts, and insulation tapes. 4. Acrylic Coating: Acrylic-based coatings offer good UV resistance, flexibility, and moisture resistance. They are commonly used for outdoor applications such as awnings, canopies, and outdoor furniture covers. 5. Vinyl Coating: Vinyl coatings provide excellent weather resistance, flame retardancy, and chemical resistance. They are commonly used for applications requiring durability and protection against harsh environmental conditions, such as truck covers, tents, and tarps. 6. Latex Coating: Latex-based coatings offer good flexibility, adhesion, and water resistance. They are often used for applications such as gloves, medical textiles, and waterproof garments. When selecting the appropriate coating option, it is important to consider the specific requirements and intended use of the glass fiber textiles.

- Q: Can glass fiber textiles be used in reinforcement of ceramics?

- Yes, glass fiber textiles can be used in the reinforcement of ceramics. Glass fibers are widely used as a reinforcing material due to their high strength, stiffness, and excellent resistance to chemical and thermal degradation. When incorporated into ceramic materials, glass fibers can enhance their mechanical properties such as tensile strength, toughness, and fracture resistance. The addition of glass fibers can also improve the overall thermal and electrical conductivity of ceramics. Furthermore, glass fibers can provide dimensional stability and prevent cracking or delamination in ceramic structures. Overall, glass fiber textiles are an effective reinforcement option for ceramics, allowing for the development of stronger and more durable ceramic materials for various applications.

- Q: Can glass fiber textiles be used in industrial filters?

- Glass fiber textiles are capable of being utilized in industrial filters. With their exceptional filtration properties, these textiles are well-suited for a wide range of industrial filtration applications. They have the ability to efficiently capture and eliminate fine particles, dust, and other impurities from air, liquids, and gases. Furthermore, they exhibit a high filtration efficiency and are capable of withstanding harsh chemical environments and high temperatures. This makes them a viable option for industries including automotive, aerospace, pharmaceuticals, and manufacturing. Additionally, glass fiber textiles are renowned for their durability, low maintenance requirements, and extended service life, thereby offering a cost-effective solution for industrial filters.

- Q: Can glass fiber textiles be used in electrical insulation?

- Yes, glass fiber textiles can be used in electrical insulation. Glass fiber textiles have excellent electrical insulation properties due to their high dielectric strength and low electrical conductivity. They can effectively isolate and protect electrical components from electrical currents and prevent any leakage or short circuits.

- Q: Can glass fiber textiles release harmful fibers?

- Improper manufacturing, handling, or maintenance of glass fiber textiles can result in the release of harmful fibers. These textiles are created by drawing molten glass into thin fibers, which can then be woven or knitted. If these fibers are damaged during production, installation, or use, they can break down into smaller particles or fibers that may become airborne and pose health risks when inhaled. The primary concern with glass fiber textiles is the release of respirable fibers, which are very small and can deeply penetrate the lungs. Inhaling these fibers can irritate the respiratory system and cause issues like coughing, wheezing, and shortness of breath. Prolonged exposure to high levels of glass fiber dust or fibers can even lead to more severe health conditions, such as lung scarring or cancer. To mitigate the risk of harmful fiber release, it is crucial to follow proper handling procedures and use suitable personal protective equipment when working with glass fiber textiles. Manufacturers should ensure the fibers are securely bound within the textile and regularly conduct quality control checks to identify any defects or damages that could result in fiber release. Additionally, regularly maintaining and cleaning glass fiber textiles can prevent the accumulation of dust and fiber particles, thereby reducing the potential for harmful fiber release. In conclusion, while glass fiber textiles have the potential to release harmful fibers if mishandled or damaged, adhering to proper manufacturing, handling, and maintenance practices can minimize the risk and ensure the safety of those working with or exposed to these materials.

- Q: Can glass fiber textile be used in composites?

- Indeed, composites can utilize glass fiber textiles. Fiberglass fabrics, commonly known as glass fiber textiles, are frequently employed as reinforcement materials in the manufacturing of composites. These textiles are composed of intricate woven glass fibers that form a fabric. The fabric can be saturated with a resin, such as polyester or epoxy, to produce a composite substance. Glass fiber textiles possess remarkable versatility and offer numerous advantages when incorporated into composites. Firstly, they possess an exceptional strength-to-weight ratio, making them ideal for applications requiring lightweight materials. Furthermore, glass fiber textiles possess high tensile strength and stiffness, which enhance the composite structure and improve its overall mechanical properties. Moreover, glass fiber textiles exhibit excellent resistance to chemicals, moisture, and UV radiation, rendering them suitable for both indoor and outdoor applications. They can be easily shaped into intricate forms and customized to specific requirements by adjusting the weave pattern, weight, and thickness of the fabric. In conclusion, the utilization of glass fiber textiles in composites is widespread due to their strength, lightweight nature, resistance to various environmental factors, and ease of customization. They have become a favored choice in industries such as aerospace, automotive, construction, and marine where the demand for robust and durable materials is substantial.

- Q: I am producing 04 cloth of glass fiber. I want to know how to sell it

- Glass cloth is mainly used for the production of a variety of electrical insulation laminates, printed circuit boards, vehicle bodies, tanks, boats, mould etc.. Glass cloth is mainly used for the production of plastic packaging cloth, as well as for corrosion resistant occasions.

- Q: Can glass fiber textiles be used for making protective clothing?

- Glass fiber textiles have the capability to be utilized in the creation of protective clothing. These textiles are produced by weaving glass fibers together, resulting in materials that possess impressive strength and resistance to high temperatures. Consequently, they are well-suited for industries involving firefighting, welding, and chemical handling, where individuals face significant risks of exposure to heat, flames, or chemicals. In fact, glass fiber textiles are highly efficient in providing insulation and shielding against heat, fire, and select chemicals, making them an optimal selection for protective clothing. Furthermore, these textiles are lightweight, flexible, and long-lasting, facilitating ease of movement and prolonged durability even in challenging environments. It is essential, however, to bear in mind that glass fibers can cause irritation to the skin and respiratory system. Therefore, it is crucial to observe appropriate precautions and safety measures when working with glass fiber textiles and wearing the resultant protective clothing.

Send your message to us

Glass Fiber Textiles Ceramic Fiber Insulation Wool Rope

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords