Geomembrana Para Estanques De Peces - Smooth Side LLDPE Geomembrane for Wastewater Treatment Lagoons

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

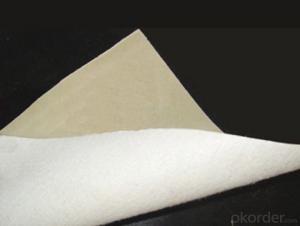

Products Specification of Smooth Side LLDPE Geomembrane for Wasterwater Treatment Lagoons

Item | Width(m) | Thickness(mm) |

LDPE geomembrane | 1-8 | 0.3-2.0 |

Physical Properties of Smooth Side LLDPE Geomembrane for Wasterwater Treatment Lagoons

Item | LDPE Geomembrane-1 | LDPE Geomembrane-2 |

Tensile Strength(Mpa) | ≥17 | ≥25 |

Fracture elongation(%) | ≥450 | ≥550 |

Tear strength(N/mm) | ≥80 | ≥110 |

Puncture resisitance(N) | 1.5mm(Thinkness)≥100 | 1.5mm(Thinkness)≥130 |

Size stability(%) | ±3.0 | ±3.0 |

Vapor permeation coefficient [g·cm/(cm2·S·Pa) | ≤1.0×10-16 | ≤1.0×10-16 |

Features of Smooth Side LLDPE Geomembrane for Wasterwater Treatment Lagoons

1. All physical factors such as anti-draw, anti-tear, and anti-stab meet the requirement of water works, chemicals, tunnels, and transportation project in most conditions.

2. Good aging, durable performance, and wide temperature range, it can be useful over thirty years on the condition of -60æ«60æ.

3. Anti-stab and fine friction factors.

4. Canker proof, acid and alkali proof, untoxic.

5. Lower cost per unit area, cost is 1/3«1/2 lower than that of PVC film, glass and cloth.

6. Convevient to install and dependable effect.

FQA:

- Q: What can we do for the special customer?

A: Provide custom made service with customer's drawing; We make sure to provide you with the best solutions for your individual case. Whether standard items or non-standard items.

- Q: What can we supply?

A: We provide high levels of communication from start to finish.

- Q: What is our advantage?

A: Top Cemented Carbide has extensive business experience, Fast delivery and high quality.

- Q: Can geomembranes be used in secondary containment systems?

- Yes, geomembranes can be used in secondary containment systems. They are commonly used as liners to prevent the leakage or seepage of hazardous materials in case of a spill or containment failure. Geomembranes provide an impermeable barrier that helps to protect the environment and prevent contamination of soil or groundwater.

- Q: What is the electrical heating?film?

- The heating principle of the electrothermal?film The so-called?film heating material is a layer of conductive film formed on the surface of insulation material after being processed on the surface of the insulation material. The conductive particles form mesh-shaped lattice structure on the surface of the insulating layer, and the various additives added in the film can adjust the power of the electrothermal?film. After being electrified, this layer of film can achieve conversion, so people also call it electrothermal?film.

- Q: What are the technical points of the lioghtweight foam?concrete?

- 1. To clean the surface and ensure that there is no dust and dirt of the grassroots, for smooth, solid, light pressure, does not allow rugged, loose and sand off ash and other defects. 2. To make a good preparation of the materials, the foaming agent, additives, cement and auxiliary materials should be transported to the designated place for storage. 3. It should be leveled according to the design. First, take use of the cement mortar according to 2.5x2.5m to determine the height of the slope. 4. To start the foaming machine to start to work, and then start the host. To sent the cement into the agitator with the help of the conveyor?belt/band carrier. And after it is mixed uniform to start the transportation system of foam conveying system and high-pressure pump. And then mix the concrete composite material averagely and transport them to the disignated construction area to cast. 5. According to the requirements of the construction, the professionals will smooth the castin foam concrete. (with help of the smooth floating ruler) Because after it is being smooth, the surface of the foam cement will produce a little air void which will have a bad effect of the surface of the waterproof construction. It is suggested to establish the 70% final set of the casting foam concrete and use the cement mortar to smooth and protect. 6. When the integral casting of foam concrete has reached 4000 square meters and the final set of the concrete has up to 70%( It is generally 25 centigrade and 36 hours). The cut of the dividing joint should be in time. And the width of the dividing joint should be bigger than 4x4m. The the width and depth of cutting of every dividing joint should be calculated by 1/800 telescopic value of the thermal efficiency expansion. The deepth of the width of cutting is 1.5x3.0cm, the elastic sealing material will be sealed in after the cutting.

- Q: What is the expected lifespan of a geomembrane in an oil storage facility?

- The expected lifespan of a geomembrane in an oil storage facility can vary depending on various factors such as the type and quality of the geomembrane material, installation techniques, maintenance practices, and environmental conditions. Generally, high-quality geomembranes made from materials like HDPE (high-density polyethylene) or PVC (polyvinyl chloride) may have an expected lifespan of 20 to 30 years or more when properly installed and maintained. However, it is recommended to regularly assess the condition of the geomembrane and conduct inspections to ensure its integrity and longevity.

- Q: Can geomembranes be used in wastewater treatment facilities?

- Yes, geomembranes can be used in wastewater treatment facilities. They are often employed as liners for containment structures such as ponds, lagoons, and tanks to prevent leakage and contamination of surrounding soil and groundwater. Geomembranes provide an impermeable barrier that enhances the efficiency and effectiveness of wastewater treatment processes, ensuring the safe management of wastewater.

- Q: How to choose glossy and matte geomembrane used in refuse landfill ?

- Hope it is easy to understand because it is not complicated at all. Actually, the dfference between matte and glossy membrane is the coarse surface, which is to increase friction. I f it is for refuse landfill, there are mainly three parts needed geomembrane for seepage-proof. reservoir bottom, side slope and cover (or closure). For "reservior bottom" , pave a layer of imported glossy geomembrane at the bottom of the landfill for horizontal seepage prevention. For side slope, use matte geomembrane around the landfill to increase friction because the side slope has vertical angle, that is, to make the geomembrane hung on the side slope. For cover or enclosure, use glossy membrane for horizontal seepage prevention to prevent rain pouring into the reservior and percolate increasing and isolate the garbage in landfill from the outside. It may not be comprehensive, but from practical experience coorperated with Canada Solmax Inc. Hope it's helpful.

- Q: What are the considerations for geomembrane selection in agricultural irrigation systems?

- When selecting a geomembrane for agricultural irrigation systems, several considerations must be taken into account. The primary factors include the type of soil, water quality, and desired lifespan of the geomembrane. Additionally, the desired application method, installation requirements, and budget constraints also play a crucial role in the selection process. It is important to choose a geomembrane that is compatible with the soil conditions, can withstand the water quality without degradation, and meets the specific design requirements for the irrigation system.

- Q: How do geomembranes contribute to stormwater filtration?

- Geomembranes contribute to stormwater filtration by acting as a barrier that prevents contaminants and pollutants from infiltrating the soil or water bodies. They are designed to be impermeable, effectively containing and controlling stormwater runoff. This helps to reduce the risk of water pollution by preventing harmful substances, such as oil, chemicals, or sediment, from reaching natural water sources. Additionally, geomembranes can be combined with other filtration systems, like geotextiles or biofiltration cells, to further enhance the stormwater treatment process.

- Q: What is the welding method of geotextile?

- It is easy to weld the geotextiles that manual rolling and paving is enough. The surface should be flat with some deformation allowance left. The long or short nonwoven geotextiles are often bonded by lapping, seaming and welding. The seamed and welded overlap is generally more than 0.1m wide. The lapped overlap is generally more than 0.2m wide. For geotextiles with long exposure time, methods of welding and seaming are recommended. Continue seaming until the all the work is completed. (disconnected seaming is not allowed.) Before being bonded, the overlaps should not be less than 150mm wide. The minimum distance of seams to the edges (the exposed edge of material) is 25mm. The thread for seaming should be made from resin with tensile strength no less than 60N, with chemical resistance and UV resistance that are the same with that of geotextile or exceed that of geotextile. Any "missed stitch" should be avoid. Actions should be taken accordingly to prevent emission of soil, particulate matters or foreign matters.

- Q: How to choose the geomembrane?

- According to different classifications, geotextile have lots of varieties. According to whether there is a clear line of latitude and longitude, the geotextile can be divided into non-woven geotextile or woven geotextile. Geotextile, especially nonwoven geotextile is rather like ordinary cotton cloth (not necessarily accurate) and most geotextiles are white. Some geotextiles contains impurities, thus showing other colors. Woven geotextile which is not waterproof is like a snakeskin bag.

1. Manufacturer Overview

| Location | Taian City,Shandong Province,China |

| Year Established | 2003 |

| Annual Output Value | Above US$100 Million |

| Main Markets | Africa, North America, Eastern Europe, South Asia, Western Europe |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port;Tianjing Port;Shanghai Port |

| Export Percentage | |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | Geotechnical Material (Geogrid,Fiberglass/Polyester Geogrid;Geocell;Geonet and Geomat;Plastic Safety Fence);Plastics products;Rubber products;Geotextile;Carpet;Compound geomembrane |

| Product Price Range | Average |

Send your message to us

Geomembrana Para Estanques De Peces - Smooth Side LLDPE Geomembrane for Wastewater Treatment Lagoons

- Loading Port:

- Qingdao

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords