Geocells Geogrid Soil Stabilization PP Biaxial Geogrid for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

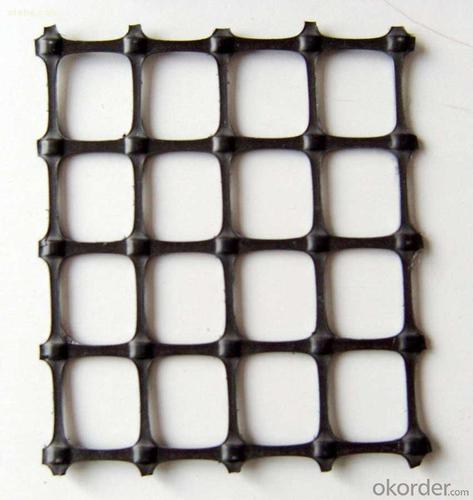

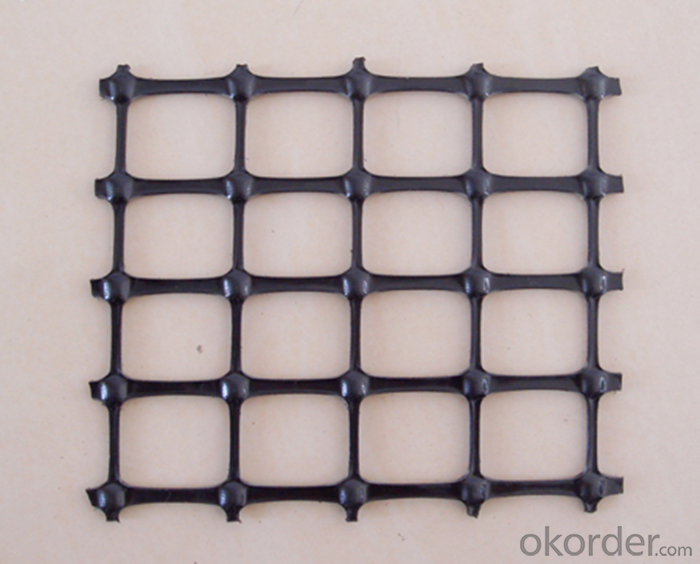

PP Plastic Biaxial Geogrid

Product Introduction

PP Plastic Biaxial Geogrid is made of high molecular polymer through extrusion, forming and punching before longitudinal and lateral stretching. This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Product Features

1. Increase the bearing capacity of the roadbed and foundation and prolong their service life.

2. Prevent road surface and foundation from sinking or flawing, keep clean and beautiful ground surface.

3. Convenient construction saves time and labor, reduce mounting time and decrease maintenance expense.

4. Prevent culverts from flawing.

5. Enhance earth slope and prevent water loss and soil erosion.

6. Decrease underlayer thickness and save manufacturing cost.

7. Enhance the stability of side slope turf net patch to improve greening.

8. Replace wire netting used in mine as intermediate ceiling netting.

Product Function

1. It can be applied in all kinds of roads, railways, airports to enhance the roadbed.

2. It can be applied in a large car park and terminal freight yard, etc. to strengthen the foundations of a permanent load;

3. It can be applied in rail, road slope's protection;

4. It can be applied to enhance the culvert;

5. It can be applied as a secondary enhancement after the uniaxial geogrid soil enhancement, further enhancement to the soil; prevent soil erosion;

6. It can be applied in mining, tunnel reinforcement.

Looking for ideal Plstic Geogrid Used For Road Construction Manufacturer & supplier ? We has a wide selection at great prices to help you get creative. All the High Strength PP Biaxial Geogrid are quality guaranteed. We are China Origin Factory of PP Biaxial Geogrid Extruded. If you have any question, please feel free to contact us.

- Q: What are the differences between geogrids and geocomposites?

- Geogrids and geocomposites are both used in soil stabilization and reinforcement applications, but they have some key differences. Geogrids are typically made from high-strength polymers or fiberglass, and they have a grid-like structure with open spaces. They are designed to provide tensile strength and distribute loads across a wider area. Geogrids are mainly used for reinforcing soils, retaining walls, and roadways. On the other hand, geocomposites are multi-layered materials that combine different geosynthetic components. They usually consist of a geotextile fabric or membrane bonded to a geogrid or geonet layer. Geocomposites offer a combination of functions such as filtration, drainage, separation, and reinforcement. They are commonly used in applications like erosion control, landfill engineering, and drainage systems. In summary, while geogrids focus on reinforcement and load distribution, geocomposites offer a more versatile solution by combining multiple functions in a single product.

- Q: 300 grams of geotextiles a square meter

- Geotextile is a kind of new material geosynthetics, the product is cloth, the general width of 4-6 meters, the length of 50-100 M. Geotextiles are divided into nonwoven geotextiles and nonwoven geotextiles.Ordinary 2 or so

- Q: Are there any limitations or drawbacks of using geogrids?

- Yes, there are limitations and drawbacks to using geogrids. Some of the limitations include the need for proper installation and compaction to achieve desired performance, as well as the requirement for an appropriate soil structure to effectively interlock with the geogrid. Additionally, geogrids may not be suitable for certain soil types, such as highly compressible or expansive soils. Other drawbacks include potential damage during installation, high cost compared to conventional soil reinforcement methods, and potential long-term degradation due to environmental factors.

- Q: Can geogrids be used in temporary construction platforms for heavy equipment?

- Yes, geogrids can be used in temporary construction platforms for heavy equipment. Geogrids provide excellent soil reinforcement and stabilization, making them suitable for supporting heavy loads during temporary construction projects. They enhance the load-bearing capacity of the soil, prevent soil erosion, and improve the overall stability of the construction platform.

- Q: Plastic two-way geogrid hole 4 cm thick, 1 mm wire width of 4 mm

- Your expression is not clear,

- Q: Can geogrids be used in subgrade stabilization applications?

- Yes, geogrids can be used in subgrade stabilization applications. Geogrids are commonly used to reinforce and stabilize weak soils in subgrade construction. They provide tensile strength and improve load distribution, ultimately enhancing the stability and performance of the subgrade.

- Q: I asked what the raw materials needed for the production were, for example, what the green mesh was made of

- The single belt is formed by the longitudinal and horizontal spacing or the clamping arrangement, and the welding joint is formed by adopting the welding technology of special strengthening bonding to weld the joint. The use of polyethylene production by Seiko weaving. Color usually green or blue.

- Q: What are the specifications of the road geogrid

- Reference to the national standard, but the specifications are not necessarily the same as the national standard.

- Q: What is the principle of geogrid?

- GSZ: 1 what are the characteristics of high strength steel wire, steel plastic composite geogrid tension by warp knitting bear, resulting in high tensile modulus at low strain capacity, vertical and horizontal rib synergistic effect, give full play to the role of Geogrid on soil type. 2, steel plastic composite geogrid vertical steel rib weft woven into nets, an outer coating layer forming a steel wire and the outer coating layer can destroy the function of coordination, elongation is very low (less than 3%). The main force unit of steel plastic composite geogrid is steel wire, and the creep is very low. 3, through the production process of plastic surface treatment, suppress the rough pattern, in order to enhance the surface roughness of the grid, improve the steel plastic composite geogrid and soil friction coefficient. 4, steel plastic composite geogrid width of up to 6m, to achieve high efficiency, economic effect of reinforcement. 5, steel plastic composite geogrid used high-density polyethylene can ensure that: at room temperature will not be affected by acid and alkali and salt solution, or oil erosion; will not be dissolved by water or microbial damage. At the same time, the high molecular weight of polyethylene is also sufficient to resist ultraviolet radiation caused by aging. The grille stress aspect rib synergistic effect, can not generate node crack or damage. But in the actual project, after the packing compaction, therefore has not been subjected to the ultraviolet light and the oxygen erosion, therefore completely may satisfy the permanent construction request.

- Q: What are the differences between uniaxial and biaxial geogrids?

- Uniaxial geogrids are designed to provide strength and stability in one primary direction, typically in the longitudinal or horizontal direction. On the other hand, biaxial geogrids are engineered to offer strength and stability in two perpendicular directions, both longitudinally and transversely. This allows biaxial geogrids to distribute loads more evenly and provide greater reinforcement in multiple directions.

Send your message to us

Geocells Geogrid Soil Stabilization PP Biaxial Geogrid for Road Reinforcement

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords