General Purpose Pumping LYB vertical arc gear pump oil pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Type: Vertical Installed Pump for Ship

Characteristic: It has characteristics low noise, long life and high efficiency.

Shaft seal: This series of pump adopt mechanical sealing. It also adopts the packing seal according to the requirement of customer.

Temperature: The max environment temperature is 50 °C and the max use temperature is 80 °C.

( If you are looking for arc gear pump used in ships, just need it -- LYB Vertical Arc Gear Pump. )

| Name | Value |

| Brand | China |

| Type | LYB arc gear pump |

| Model | LYB VERTICAL ARC GEAR PUMP |

| Temperature | Environmental temperature: <50°c Use temperature: <80°c |

| Viscosity | 5~1500cSt |

| Rated pressure | 0.6Mpa |

| Frequency | 50Hz 60Hz |

| Certification | GL, ABS, BV, CE, CNV etc. |

| Deliever time | About 25~40 days according to quantity. |

More Details:

| MOQ | 1 SET |

| Certification | GL, ABS,BV, CE, 3C, ISO9001-2000, GJB9001A-2001 |

| Package | Standard export carton or plywood case. (By sea or by air) |

| Deliver date | Within 25 working days after confirm orther |

| Warranty | 1 year |

| Customized | Available |

LYB arc gear pump

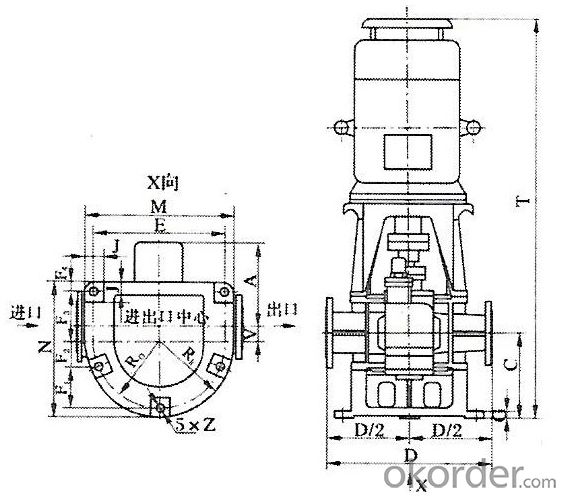

Outline and Installation diagram

Performance parameter

Rated pressure: 0.6Mpa

| Model | Diameter | Rated Capacity(m3/h) | |||

| Inlet*Outlet | 60Hz | 50Hz | |||

| 1180rpm | 900rpm | 970rpm | 720rpm | ||

| LYB20 | Φ100*Φ80 | 24 | - | 20 | - |

| LYB25 | 30 | - | 25 | - | |

| LYB30 | Φ125*Φ100 | 36 | - | 30 | - |

| LYB40 | Φ150*Φ125 | 48 | - | 40 | - |

| LYB50 | Φ150*Φ125 | 61 | - | 50 | - |

| LYB65 | - | 65 | - | 55 | |

| LYB80 | - | 80 | - | 65 | |

| LYB90 | - | 90 | - | 75 | |

| LYB100 | Φ200*Φ150 | - | 100 | - | 85 |

| LYB150 | - | 150 | - | 125 | |

| LYB175 | Φ250*Φ200 | - | 175 | - | 145 |

| LYB200 | - | 200 | - | 165 | |

All Products can be matched with different motors as customer's requirment

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

| | | | | | |

- Q: Fire hydrant pump button, under what circumstances do not need to install?

- General high voltage system, when normal, use small pump steady pressure.Fire hydrant button lifting pump is one of the multiple pumping methods, and it is an important link of reliable operation of the system.

- Q: What is the pump lift voltage? And how to suppress the pumping voltage rise?

- [pump voltage] when braking, in the motor winding series resistance, motor equivalent to the generator, the energy will be converted to electric energy consumption in the series resistance. This method is widely used in all kinds of motor braking, and frequency conversion control is also used. From high to low (zero speed), then the electrical frequency changes quickly, but the rotor of the motor with the load (production machinery) mechanical inertia, could not stop quickly, resulting in the back EMF (EU voltage) motor is in the state of power,

- Q: The water tank of the fish tank does not air out and only has the water outlet

- The air inlet pipe is connected with the oxygen burst, the entrance also pulled out, we can see that it is the design of a miter, the oblique incision back to the direction of the water flow speed, this outflow, negative pressure is formed in the oblique incision, the air can be sucked in. As shown.

- Q: What are the causes of pump shock?

- 6., water pump relatively serious cavitation, improve the water level of the water tank, reduce water output7., impeller and motor rotor imbalance, overhaul8. pump shaft bending or abrasion overhaul

- Q: The difference between diaphragm pumps, vacuum pumps and centrifugal pumps

- The diaphragm pump and centrifugal pump refer to the structure of the pump, and the vacuum pump means the use of the pump. There is no comparability between them.Centrifugal is the sign of inertia of an object. As the umbrella turns, water droplets move out of the outer edge of the umbrella and are thrown out. This is what is called centrifugal. Centrifugal pump is designed according to this principle. The high speed rotating impeller blade drives the medium to rotate and is thrown out so as to achieve the purpose of conveying.

- Q: Fire control center manually start the fire pump directly, multi line control, called straight up line NHKVV-7*1.5, my understanding is: straight line from fire control center

- Multi line linkage NHBVR-4*1.5 is a positive pressure blower and smoke exhaust machine fire fighting equipment

- Q: Is the centrifugal pump large or small?

- Centrifugal pump, the smaller the better the cavitation.1, centrifugal pump cavitation less, anti cavitation performance is better, the pump cavitation is called the necessary cavitation margin or pump inlet dynamic pressure drop, the smaller the better. Generally speaking, the pump cavitation is the need for cavitation, the pump inlet pipe said effective cavitation margin, that is, the device cavitation margin. For a given pump, at a given speed and flow rate required NPSH is called pump necessary NPSH, also called NPSH, is required to achieve the performance parameters of the pump cavitation, the internal flow and the centrifugal pump is composed of pump head itself, its physical meaning is that liquid drop in pump inlet pressure part degree, is to guarantee the pump cavitation does not occur, with surplus energy exceeds the vaporization pressure head at the inlet of the pump unit weight of liquid. The cavitation must be independent of the device parameters. It is only related to the parameters of the inlet of the pump. These parameters are determined by the geometric parameters at a given speed and flow.

- Q: Working principle and structure of external gear pump

- External gear pump is the most widely used gear pump, the general gear pump usually refers to the external gear pump. Its structure as shown in the diagram, there are mainly driving gear, driven gear, pump body, pump cover and safety valve and so on. The seal space of pump body, pump cover and gear is the workshop of gear pump. The wheel shafts of the two gears are respectively arranged in the bearing holes on the two pump cover, and the driving gear shaft extends out of the pump body and is driven by the motor to rotate. The external gear pump is simple in structure, light in weight, low in cost, reliable in operation and wide in application. When the gear pump works, the driving wheel rotates with the motor and drives the driven wheel to rotate

- Q: What's the difference between a concrete pump and a concrete pump truck?

- Concrete pump is a pumping machine used in the field, while the concrete pump truck is a truck mounted pump.

- Q: What flowmeter is installed after the pneumatic diaphragm pump?

- The pressure decreases, the diaphragm moves slowly, and the flow decreases.This is not particularly accurate, because the diaphragm is not a metering pump, but the approximate flow can still be controlled.

Send your message to us

General Purpose Pumping LYB vertical arc gear pump oil pump

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords