GB Standard Steel H Beam 200*200*8.0mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of GB Standard Steel H Beam 200*200*8.0mm with Good Quality For Sale:

1. Standard: GB Standard

2. Grade: Q235

3. Length: 12m

Size and Mass:

| Size (mm) | Mass (Kg/m) | Size (mm) | Mass (Kg/m) |

| 200*200*8.0 | 49.9 | 250*125*6.0 | 29.0 |

| 248*124*5.0 | 25.1 | 244*175*7.0 | 43.6 |

Usage & Applications of GB Standard Steel H Beam 200*200*8.0mm with Good Quality For Sale:

Commercial building structure ;Pre-engineered buildings; Machinery support structure; Prefabricated structure; Medium scale bridges; Ship-building structure.etc.

Production flow of GB Standard Steel H Beam 200*200*8.0mm with Good Quality:

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will arrange production. The shipping date is dependent upon the quatity, how many sizes you want and the plan of production, but is typically 1 month to 2 month days from the beginning of production.

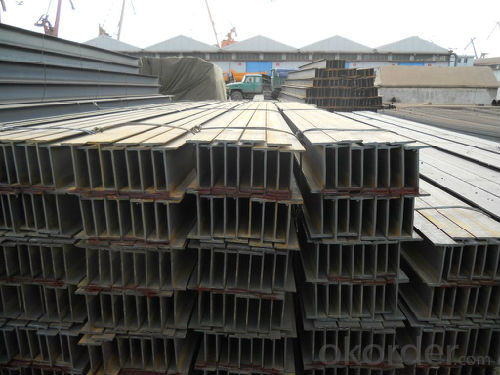

Images of GB Standard Steel H Beam 200*200*8.0mm with Good Quality:

*If you would like to get our price, please inform us the size, standard/material and quantity. Thank you very much for your attention.

- Q: Can steel H-beams be used in the construction of shopping malls?

- Yes, steel H-beams can be used in the construction of shopping malls. Steel H-beams are commonly used in the construction industry due to their strength and durability. They provide structural support and are often used in the construction of large buildings, including shopping malls. Steel H-beams can withstand heavy loads and provide stability, making them an ideal choice for constructing the framework of shopping malls. Additionally, steel is a sustainable and cost-effective material, making it a popular choice in commercial construction projects.

- Q: How do Steel H-Beams contribute to the overall natural ventilation of a structure?

- Steel H-Beams do not directly contribute to the natural ventilation of a structure. Their primary function is to provide structural support and distribute the load of the building. However, the design and construction of a structure using steel H-Beams can allow for the incorporation of ventilation systems such as windows, vents, and openings, which can enhance natural airflow and ventilation within the building.

- Q: How do steel H-beams contribute to the overall aesthetics of a structure?

- Steel H-beams contribute to the overall aesthetics of a structure by providing a sleek and modern appearance. Their clean lines and minimalistic design create a sense of sophistication and elegance. Additionally, steel H-beams allow for larger open spaces and flexible architectural designs, enhancing the overall aesthetic appeal of the structure.

- Q: How are steel H-beams installed in construction projects?

- Steel H-beams are commonly used in construction projects due to their strength and durability. The installation process involves several steps to ensure that the beams are properly positioned and secured. Firstly, the foundation or base for the H-beams is prepared. This typically involves excavating the ground and pouring concrete footings or constructing a reinforced concrete slab. The design and dimensions of the foundation are determined by the structural engineer based on the load-bearing requirements. Once the foundation is ready, the H-beams are transported to the construction site. They are usually delivered in sections, as the length of the beams can be quite long. The sections are unloaded using cranes or forklifts and carefully placed next to the foundation. Next, the H-beams are aligned and positioned according to the construction plans. This involves using laser levels, surveying instruments, or other tools to ensure precise placement. The beams are usually connected to the foundation using anchor bolts or welded plates, depending on the design specifications. After the beams are aligned and secured to the foundation, they are connected to each other. This is typically done by welding or bolting the beams together at the flanges and web. Welding is often the preferred method as it provides a stronger and more rigid connection. Once all the H-beams are installed and connected, additional structural components such as columns, braces, and cross beams are added to complete the framework of the structure. These components are also securely attached to the H-beams using welding or bolting methods. Throughout the installation process, safety measures are followed to ensure the protection of the workers and the integrity of the structure. This includes using appropriate personal protective equipment, following proper lifting and rigging procedures, and adhering to construction standards and regulations. In conclusion, the installation of steel H-beams in construction projects involves preparing the foundation, aligning and positioning the beams, connecting them to the foundation and to each other, and adding additional structural components. This process requires careful planning, precise measurements, and adherence to safety protocols to ensure a successful and sturdy construction.

- Q: What are the factors that determine the load-bearing capacity of steel H-beams?

- Various factors determine the load-bearing capacity of steel H-beams. Firstly, the material properties of the steel used are crucial. The steel's yield strength, ultimate tensile strength, and modulus of elasticity determine its ability to withstand external loads without deformation or failure. Stronger steel with higher yield strength and ultimate tensile strength values can carry heavier loads. Secondly, the size and shape of the H-beam greatly affect its load-bearing capacity. The beam's height and width, known as the web and flange dimensions, respectively, determine the cross-sectional area and moment of inertia. Larger dimensions result in a larger cross-sectional area and moment of inertia, increasing the load-bearing capacity. The thickness of the web and flanges also impacts the beam's strength, as thicker sections can handle higher loads. Thirdly, the length of the H-beam is an important factor. Longer beams tend to have reduced load-bearing capacities compared to shorter ones due to the risk of buckling under compression loads. Therefore, the beam's length must be carefully considered when determining its load-bearing capacity. Additionally, the type and distribution of the load applied to the H-beam are significant factors. Different load types, such as point loads, distributed loads, or dynamic loads, exert different stress distributions on the beam. The load distribution pattern and magnitude must be taken into account when calculating the load-bearing capacity. Moreover, the support conditions of the H-beam, including the type of connections and the presence of additional supports, impact its load-bearing capacity. The beam's connections to other structural elements, such as columns or beams, affect its ability to transfer loads effectively. Properly designed connections and additional supports can enhance the load-bearing capacity. Lastly, it is important to consider the design codes and standards followed during the manufacturing and installation of the H-beam. These codes provide guidelines and specifications for the safe design and construction of structures, ensuring accurate calculation of load-bearing capacities and the incorporation of appropriate safety margins. In summary, the load-bearing capacity of steel H-beams depends on material properties, dimensions, length, type and distribution of load, support conditions, and adherence to design codes. Considering these factors is crucial for ensuring the structural integrity and safety of buildings and other structures where H-beams are used.

- Q: What are the design considerations for steel H-beams in coastal areas?

- Several important factors need to be considered when designing steel H-beams for coastal areas in order to ensure their durability and longevity in the harsh and corrosive environment. 1. To combat corrosion, it is crucial to select steel with excellent corrosion-resistant properties, such as stainless steel or galvanized steel. These materials have protective coatings that can withstand the corrosive nature of the coastal environment where high levels of saltwater and humidity are present. 2. The strong winds and storms commonly experienced in coastal regions exert significant forces on the H-beams. Designers should take into account the wind load and ensure that the H-beams are adequately sized and reinforced to withstand these forces. Additionally, proper connections and fasteners should be utilized to maintain the structural integrity of the H-beams during extreme weather events. 3. Erosion and scour pose a risk to the stability of the H-beams in coastal areas. It is important to consider the soil conditions and design appropriate foundations for the H-beams to mitigate this risk. Additional measures such as using extra piling or protective barriers can be implemented to prevent erosion and scour around the H-beams. 4. Regular maintenance and inspection are essential for steel H-beams in coastal areas due to the harsh environment. This includes periodic cleaning, repainting, and inspection for signs of corrosion or damage. Implementing a diligent maintenance plan will help extend the lifespan of the H-beams. 5. Environmental impact should also be taken into consideration when designing H-beams for coastal areas. Coastal regions often have unique ecosystems and wildlife habitats, so designers should minimize disruption by using environmentally friendly coatings, avoiding sensitive areas, and implementing mitigation measures such as bird deterrents. In conclusion, the design of steel H-beams for coastal areas should consider factors such as corrosion resistance, wind load, erosion and scour, maintenance and inspection, and environmental impact. By addressing these considerations, engineers can ensure the durability and resilience of the H-beams in the challenging coastal environment.

- Q: What are the different methods of protecting steel H-beams from corrosion?

- There are several methods of protecting steel H-beams from corrosion. One common method is applying a protective coating such as paint or epoxy. This creates a barrier between the steel and the corrosive elements in the environment. Another method is galvanizing, where a layer of zinc is applied to the steel through a process called hot-dip galvanizing. This zinc coating acts as a sacrificial layer, corroding before the steel does. Additionally, using stainless steel H-beams can provide inherent corrosion resistance due to their composition. Regular maintenance and inspection to identify and address any signs of corrosion is also crucial in protecting steel H-beams from corrosion.

- Q: How do steel H-beams perform in areas with high levels of humidity or moisture?

- Steel H-beams perform well in areas with high levels of humidity or moisture. Due to their inherent strength and durability, steel H-beams are resistant to corrosion and rust formation, even in humid environments. This is primarily due to the protective coating, such as galvanization or epoxy paint, applied to the steel surface, which acts as a barrier against moisture and prevents the steel from coming into direct contact with the humid air. Additionally, the design of H-beams allows for efficient drainage of any accumulated water, further enhancing their performance in wet conditions. Therefore, steel H-beams are suitable and reliable for use in areas with high levels of humidity or moisture.

- Q: Can steel H-beams be used for parking structures?

- Yes, steel H-beams can be used for parking structures. They are commonly used in the construction of multi-level parking garages due to their strength, durability, and load-bearing capabilities. The H-beams provide structural support and stability to the parking structure, making them a suitable choice for this application.

- Q: How are steel H-beams used in bridge construction?

- Steel H-beams are a popular choice in bridge construction because of their strength, versatility, and cost-effectiveness. These beams are designed specifically to bear heavy loads and provide structural stability, making them ideal for building bridges. When constructing bridges, steel H-beams are primarily used as the main structural elements. They support the weight of the bridge deck and transfer the load to the bridge piers or abutments. The H-shape of these beams allows for even weight distribution and excellent load-bearing capabilities. Another advantage of steel H-beams in bridge construction is their flexibility in fabrication. They can be easily made to the required length and size, allowing engineers to design bridges of various spans and heights to suit different site conditions. Furthermore, steel H-beams offer a high strength-to-weight ratio. This means they can support heavy loads without being excessively bulky or heavy themselves. This advantage is particularly valuable for long-span bridges, where reducing the weight of the structure is important to minimize material and construction costs. In addition, steel H-beams have excellent durability and resistance to corrosion. This is crucial for bridges exposed to harsh weather conditions and environmental factors. The steel used in these beams is often treated with protective coatings or galvanized to enhance its longevity and prevent deterioration over time. In conclusion, steel H-beams are essential in bridge construction as they provide the necessary strength, versatility, and durability to support heavy loads and maintain the structural integrity of the bridge. Their use enables efficient and cost-effective bridge designs that can withstand the test of time.

Send your message to us

GB Standard Steel H Beam 200*200*8.0mm with Good Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 40 m.t

- Supply Capability:

- 15000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches