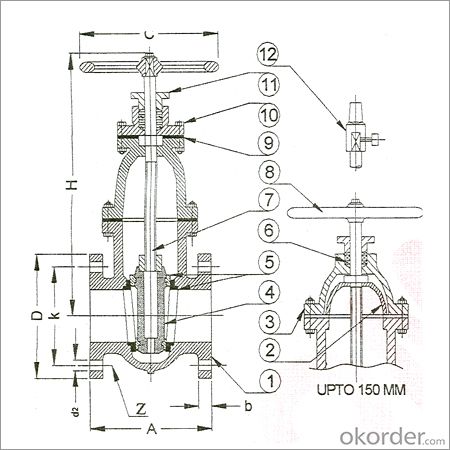

Gate Valve with Prices, Cast Iron Gate Valve Drawing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q: What are the advantages and disadvantages of flat gate valves?

- The advantage of flat gate valve is that the flow resistance is small, and the flow resistance is similar to the flow resistance of short valve. The flat gate valve with guide hole is installed on the pipeline and can be directly cleaned with the cleaner. As the gate is sliding on the two seat surface, the flat gate valve can be applied to the medium with suspended particles, and the sealing surface of the flat gate valve is actually positioned automatically. The seat seal surface is not subject to thermal deformation of the valve body. Moreover, even if the valve is closed in cold condition, the thermal elongation of the stem will not cause the seal to be subjected to overload. The length of the structure is much shorter than that of the ball valve, and it is easier to start. Light plate gate valve is more refined, but the effect is exactly the same.The disadvantage of flat gate valve is that when the medium pressure is low, the sealing force of the metal sealing surface is insufficient, so as to achieve satisfactory sealing. On the contrary, when the medium pressure is high, if the sealing surface is not lubricated by the system media or foreign media, often opening and closing may cause the sealing surface to wear too much. Another disadvantage is that the circular motion of the circular gate in the circular flow, only when it is at the valve closed position of 50%, this valve is more sensitive to flow control. Moreover, the gate will produce severe vibration when it breaks the high-speed and dense medium flow. The valve seat can also be throttled if the seat is made of a V - shaped opening and is tightly oriented to the gate.

- Q: Analysis of the advantages of elastic seat sealing gate valve?

- General valve on the market for a long time there is Water Leakage or rusting, overcome the valve seal bad, rust and other defects, using the elastic elastic valve seat seal gate produce small quantities of elastic deformation of the compensation function to achieve a good sealing effect, with a switch to lighter and reliable sealing, good elastic memory and life and other significant advantages. The utility model can be widely used as an adjusting and intercepting device for pipelines such as water supply, sewage, building, petroleum, chemical industry, food, medicine, light industry, electric power, ship, metallurgy, energy system, etc.. This is the advantage and advantage of an elastic seat seal gate valve.

- Q: What does Z941H-25DN250 mean by electric gate valve (excluding electric equipment)?

- Cast steel flanged gate valve 25 pressure bore 250

- Q: Z41T one 10 gate valve and Z44T one, 10 gate valve difference

- Z41T one, 10 is single gate, Z44T one, 10 is double gateAccording to the provisions of the JB/T 308-2004 valve type programming method:Z== gate valve4== connection: flange type1== structure: Rigid single gate4== structure: Rigid double gateT== sealing surface material: copper alloy10== pressure rating: 1.0MPa

- Q: Why? God, can you explain to me in detail why?

- Check valve in the valve in front. To prevent water from flowing back.

- Q: What is the meaning of socket welding gate valve A105, D&S:STLT, STEM:13Cr, CL800, SW, AP1602, BB-BG-OS&Y?

- Body material: A105Sealing surface material: STLStem material: 13CrPressure rating: CL800Connection: SWImplementation criteria: AP1602BB-BG-OS&Y: plain rod support, bolt connection, flange valve cap.

- Q: What is the difference between an elastic gate valve and a rigid gate?

- Brief introduction: the valve gate valve is a gate opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle. Gate has two sealing surface, the most commonly used mode gate valve of the two sealing surface to form a wedge, wedge angle with valve parameters vary, usually 50, medium temperature is not high when 2 degrees 52'.Wedge gate valve can be made into a whole, called the rigid gate; can also be made to produce micro deformation of ram, in order to improve its process of deviation, make up the sealing surface angle in the process, the gate is called the flexible gate.

- Q: Which is the most expensive, check valve and gate valve?

- In the case of DN50 Z15T-16 DN50: screw valve 46.200 thread copper bar gate valve Z15T-16 DN50 52 Z45F-16 DN50 97 flange valve flange valve rod Z44T-10 DN50 169 Z45T-116 DN50 flange valve dark bar 173 thread swing check valves DN50 52.090 thread straight type check valve DN50 57.280 flange screw check H44T DN50 129 flange valve lift check valve H41T-16 DN50 124

- Q: The main question is, what are the functional differences in which case?

- The gate (gate valve) is a gate opening and closing parts, RAM direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle gate valve. The direction of motion perpendicular to the direction of the fluid, valve can only be fully open and fully closed, can not be adjusted and the throttle.Gate valve advantages: 1, fluid resistance is small,.2, opening and closing more labor-saving,.3, medium flow unrestricted, not disturbed flow, do not reduce pressure,.4, simple shape, structural length is short, manufacturing process is good, a wide range of applicationsValve shortcomings: 1, between the sealing surface is easy to cause erosion and abrasions, maintenance is more difficult,.2, big size, open need some space, opening and closing time is long,.3, the structure is more complex

- Q: Fire protection gate valve from the wall how many distance there is no regulation?

- 1 meters away from the wall, leaving the maintenance and replacement distance

Send your message to us

Gate Valve with Prices, Cast Iron Gate Valve Drawing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 150 kg

- Supply Capability:

- 10000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords