Gate Valve with Competitive Price with Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Gate Valve Description:

A gate valve, also known as a sluice valve, is a valve that opens by lifting a round or rectangular gate/wedge out of the path of the fluid. The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry. For extremely thick fluids, a specialty valve often known as a knife valve is used to cut through the liquid. On opening the gate valve, the flow path is enlarged in a highly nonlinear manner with respect to percent of opening. This means that flow rate does not change evenly with stem travel. Also, a partially open gate disk tends to vibrate from the fluid flow. Most of the flow change occurs near shutoff with a relatively high fluid velocity causing disk and seat wear and eventual leakage if used to regulate flow. Typical gate valves are designed to be fully opened or closed.When fully open, the typical gate valve has no obstruction in the flow path, resulting in very low friction loss.

2. Main Features of the Gate Valve:

• Valve body cavity using non-toxic epoxy resin,both inside and outside flashboard completely is coated with rubber

• Free of water pollution

• High manufacturing accuracy

• High strength

• Environmental protection and energy saving

• Good visual effect

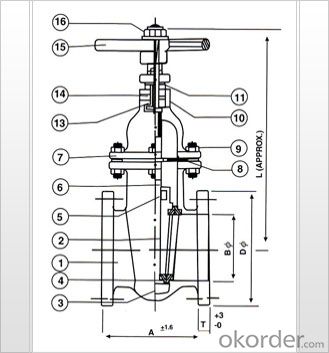

3. Images

4. Gate valve Specification

5.FAQ

1. What's are the characteristics of gate valve?

The distinct feature of a gate valve is the sealing surfaces between the gate and seats are planar, so gate valves are often used when a straight-line flow of fluid and minimum restriction is desired. The gate faces can form a wedge shape or they can be parallel.

2. What is the work principle of gate valve ?

The gate faces can form a wedge shape or they can be parallel. Gate valves are primarily used to permit or prevent the flow of liquids, but typical gate valves shouldn't be used for regulating flow, unless they are specifically designed for that purpose. Because of their ability to cut through liquids, gate valves are often used in the petroleum industry.

3. What is the structure?

Bonnets provide leakproof closure for the valve body. Gate valves may have a screw-in, union, or bolted bonnet. Screw-in bonnet is the simplest, offering a durable, pressure-tight seal. Union bonnet is suitable for applications requiring frequent inspection and cleaning. It also gives the body added strength. Bolted bonnet is used for larger valves and higher pressure applications.

- Q:What is plug welding gate valve?

- Plug connection pipeline welding mode safety gate valve

- Q:Analysis of the advantages of elastic seat sealing gate valve?

- Most of the valve is forced seal, that is, when the valve closed, to rely on external force to force the gate to the seat, in order to ensure the sealing surface sealing.When opening the gate valve, when the gate lift height is equal to 1:1 times of the gate diameter, the passage of the fluid is completely unblocked, but at run time, this position is unable to monitor. In actual use, the top of the stem is used as a sign, i.e., the open position, as its fully open position. Temperature changes appear to consider locking phenomenon, usually open to the vertex position, and then rewind 1/2-1 circle, as a fully open valve position. Therefore, the opening position of the gate valve is determined by the position of the gate (i.e. the stroke). The sealing surface is easy to wear and tear, affecting the service life. When opening and closing, gate and valve seat two sealing surface friction, sliding, to medium pressure under the action of easy to produce abrasions, wear, affect sealing performance, shorten service life.

- Q:What's the difference between the knife gate valve and the stop valve?

- Generally large and nominal caliber DN50 mostly with gate valve, especially industrial high temperature, high pressure, highly toxic and so on.Stop valve is able to stop and adjust flow, small footprint, small size, generally less than the nominal diameter, DN50 occasions use it. Two can be closed, in the flow of linear requirements are not high, you can adjust the flow. Just because of its structural characteristics of the valve to make its flow resistance, so there is a demand for throttling with a little more than the gate valve. In addition, the cut-off valve, whether it is a formal or reverse installed, in the opening and closing process, there is always a very difficult, and therefore can not do a great deal, or it is not easy to open and close. In addition, the cut-off valve has a one-way sealing effect of good features, so in the prevention of reverse flow of the working fluid, it also has a place to play.Hope to be of some help to you!

- Q:What is the allowable leakage rate of the gate valve D?

- In GB/T 13927, the leakage rate of the valve is divided into 10 grades, namely: A, AA, B, C, CC, D, E, EE, F, G class. And stipulates that when the order contract does not specify, the metal sealing valve according to D requirements.

- Q:Function of signal butterfly valve and gate valve

- The signal butterfly valve applies to petroleum, chemical, food, medicine, papermaking, water and electricity, ships, water supply and drainage, smelting, energy and other system pipelines. It can be used as regulating and throttling devices in a variety of corrosive, non corrosive gases, liquids, semi fluids, and solid powder pipelines and containers. It is widely used in high buildings, fire protection systems and other piping systems that need to display valve switching status.

- Q:Why the valve can only be fully open and fully closed valve can adjust the flow?

- Gate valve, stop valve are switching type valve, adjust the flow can not talk about, can only do so called throttle.You say "stop valve" or "translation" problem, in English, globe valve and valve word is often the same.

- Q:What is gate valve (with force transfer joint)?

- Flange valve is equipped with a force expansion joints, easy installation

- Q:Yes, soft sealing gate valve can reach 25 kilograms, Fujian light valve company has this type of soft sealing gate valveAnonymous browsing | 28 times

- Soft seal butterfly valve seal is good, but can only withstand up to 16 pressure, or the plastic can not stand. A short period of time is OK, and it's also related to the workmanship and quality of the factory. The quality is poor.

- Q:Fire protection gate valve from the wall how many distance there is no regulation?

- Don't know don't answer. "According to the provisions of article 6.2.13 GB50038-2005" code for design of basement for civil air defense engineering, into or through the door unit between the door closed wall should be set up in the inner side or two nominal pressure pipeline is not less than 1.0MPa, the spool is stainless steel or copper gate or globe valve water pipe from the air enclosure structure. The installation position from the wall should be not more than 200mm.

- Q:What does "Z45W-10T" mean?What does each letter stand for?

- For type PN10 Z45W Brass Gate ValvesZ is the valve type code, which represents the gate valve;Driving mode is hand wheel (code name omitted);4 is the connection form code, which represents the flange;5 is the gate valve structure form code, represents for the dark pole wedge rigid single gate;

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Gate Valve with Competitive Price with Manufacturer

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products