Galvanized Steel Sheet in High Quality Hot Selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

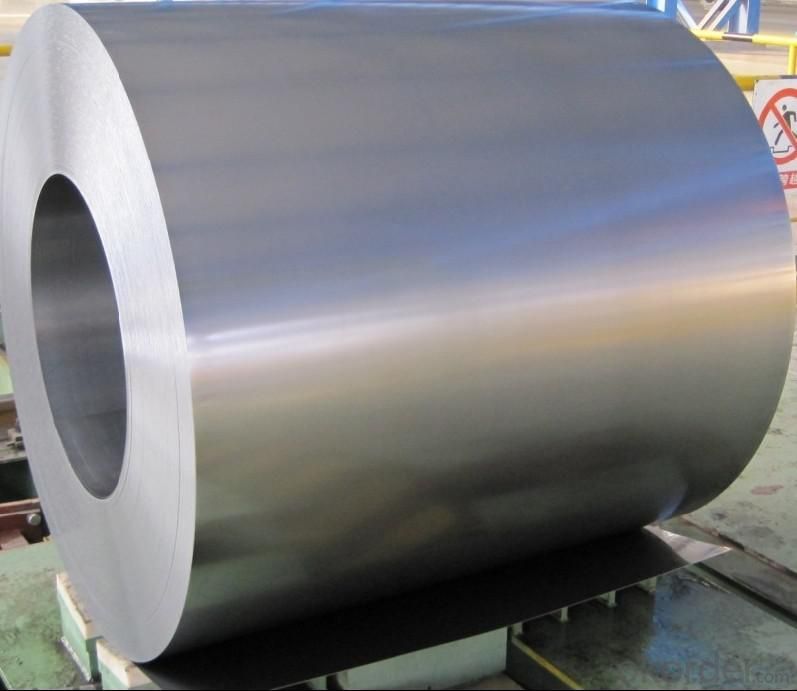

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

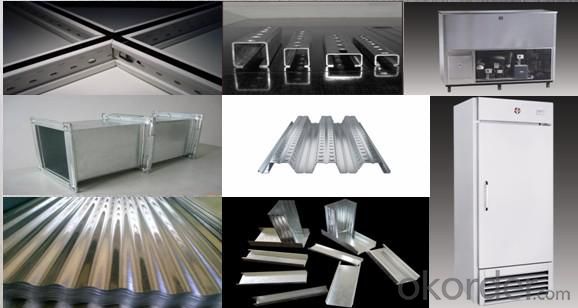

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

3.Hot-Dip Galvanized Steel Sheet Images:

4.Hot-Dip Galvanized Steel Sheet Specification:

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

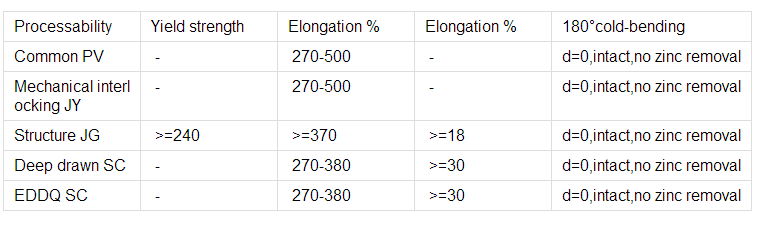

Technology test results:

5.FAQ of Hot-Dip Galvanized Steel Sheet:

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: What are the common tests performed on steel coils?

- Common tests performed on steel coils include visual inspection, dimensional measurement, tensile strength testing, hardness testing, surface finish evaluation, and coating thickness measurement. Additionally, other specialized tests like bend testing, impact testing, and corrosion resistance testing may also be performed depending on the specific requirements and application of the steel coils.

- Q: I am going to be working as a mechanic at my school and I just wanted to know if I should get the steel toe boots or regular. I heard that steel toe boots can be dangerous and uncomfortable. The mechanics recommended getting steel toe to be safe but i'm not sure.

- Steel toe boots they protect your feet and toes a lot better and if u are going to be working they would be better to have than soft toe boots

- Q: Why are properties of steel not identical?

- Steel is manufactured to different specs. To match the needs of its intended end use .Tensel strength,Hardness, Corosion resistance etc. The chemical make up will change to suit.

- Q: How are steel coils processed before they are used in manufacturing?

- Steel coils undergo several processing steps before they are used in manufacturing. The first step is called pickling, where the coils are immersed in an acid bath to remove any surface impurities, such as rust or scale. This helps to improve the surface quality of the steel. After pickling, the coils go through a process called cold rolling. This involves passing the coils through a series of rollers to reduce their thickness and improve their dimensional accuracy. Cold rolling also enhances the mechanical properties of the steel, making it stronger and more durable. Next, the coils are annealed, which involves heating them to a specific temperature and then slowly cooling them. Annealing helps to relieve internal stresses in the steel and improves its formability and ductility. Following the annealing process, the coils may undergo additional surface treatments, such as galvanizing or coating. Galvanizing involves applying a layer of zinc to protect the steel from corrosion, while coating can involve applying various types of paint or polymer to enhance the steel's appearance or provide specific functionalities. Once the coils have been processed and treated, they are typically cut into smaller sheets or strips, depending on the manufacturing requirements. These sheets or strips can then be used in various manufacturing processes, such as stamping, forming, welding, or fabrication, to create a wide range of products, including automotive components, appliances, construction materials, and many others. In conclusion, steel coils undergo a series of processing steps, including pickling, cold rolling, annealing, and surface treatments, before they are ready to be used in manufacturing. These processes improve the quality, strength, and formability of the steel, allowing it to be transformed into a variety of products.

- Q: How are steel coils used in the production of steel brackets?

- Steel coils are used in the production of steel brackets as they serve as the primary raw material. The coils are processed through various manufacturing techniques such as cutting, bending, and welding to shape and form the brackets. The high strength and durability of steel coils ensure that the brackets maintain their structural integrity and can withstand heavy loads or harsh conditions.

- Q: can steel boil and turn into a gaseous state?? if so how hot does it have to be for it to boil

- I can't, but it can be done with the right machinery. For iron, it melts at 1538?C (2800?F) and boils at 2862?C (5182?F) Steel is an alloy of iron and various other materials, depending on which alloy it is. The boiling point will depend on the exact alloy and it's composition. Approximate boiling point for common steel is 3000°C (5400°F) .

- Q: is red steel any good??????? not sure im really impressed but im not really into fighting games but it looks cool.... so whats your views guys???????anyone bored of smooth moves yet?anyone think the new sonic is bit cra ppy !!!!!!!!!!! darn them any new goooood games coming oput on the wii??

- Have you tried Zelda or Trauma Center? Those should give you a good ride for your money. If you have a few bucks lying around pick either of them up.

- Q: What are the challenges in coil blanking for complex shapes?

- Coil blanking for complex shapes poses several challenges, primarily due to the intricate nature of the shapes involved. One significant challenge is achieving precision and accuracy in cutting the coils to create the desired shape. Complex shapes often require intricate cuts and tight tolerances, which necessitates advanced cutting techniques and machinery. Additionally, maintaining consistency throughout the entire coil length can be challenging, as any deviation can result in imperfect shapes. Furthermore, handling and manipulating the coils during the blanking process can be difficult, especially if the shapes are intricate or delicate. Overall, the challenges in coil blanking for complex shapes revolve around achieving precise cuts, maintaining consistency, and effectively handling the coils to ensure high-quality finished products.

- Q: How are steel coils protected against UV radiation?

- Steel coils are protected against UV radiation through the application of protective coatings or paints. These coatings act as a barrier, shielding the steel from direct exposure to UV rays, preventing oxidation and degradation of the metal.

- Q: Is it possible to make a homemade blacksmith forge from a washing machine drum made of stainless steel?

- Homemade Blacksmith Forge

Send your message to us

Galvanized Steel Sheet in High Quality Hot Selling

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 7000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords