FSK Roofing Insulation Adhesive Heat Insulation Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Description:

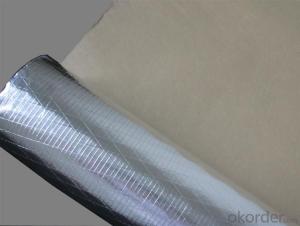

FSK7180 is the most popular laminated thermal insulation sheeting for covering ducts and pipes wrapped up by a thermal insulator such as glass wool and rock wool, PU foam and other insulation to protect them against vapor moisture in order to work more effectively, includes an reflective aluminum sheet and a fiberglass network disposed on and over a surface of the aluminum sheet

2. Construction & Benefits:

Reflective Aluminum Foil Lined With Kraft and Reinforced by fiberglass from 3 directions make this products durable. This Kind of FSK have more fiberglass as Scrim. So that thisFSK 7180 have more strength than FSK 7160

Aluminum foil which is a good barrier to moisture, rust and the air, and friendly to environment, good conductivity from the aluminum layer eliminates the electrostatic effect easily as exposure and kraft being liner to rise the strength, they sandwiched together through polyethylene as adhesive.

l High performance cost ratio: reasonable price and professional service.

l Environment friendly: it does not contain any hazardous or harmful materials.

l Convenient to use, easy to be folded into various shapes according to actual needs.

l Better resistance and tenacity according to glass fiber within.

l Reduces heat loss in winter, heat gain in summer.

l Not effected by moisture and humidity.

l No special handling or breathing protection required.

3. Application:

It could be used as reflection, packing paper, moisture proof, radiant barrier and easy to fold as your need.

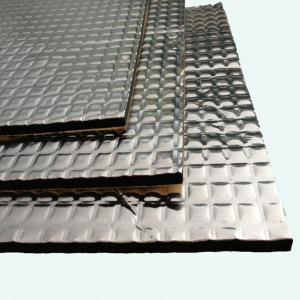

1. As a heat insulation materials in car, train, roof and wall, also been attached to glass wool blanket, rock wool board, mineral wool for get better performance.

2. A laminated thermal insulation sheeting. for covering ducts and pipes wrapped up by a thermal insulator such as glass wool and rock wool, PU foam and other insulation to protect them against vapor moisture in order to work more effectively.

3. As a sound absorber in KTV room, cinema, opera house, factory and other building.(only indicates 7160P, 7150P)

4. Package of industrial products and other place that you want to use.

4. Dimension/Size

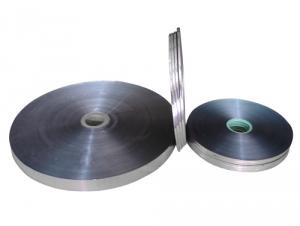

(1) Roll width: 1000mm, 1200mm and 1250mm

(2) Roll Length: 50m, 100m, 200m, 500m, 1000m, or upon request.

(3) Core I. D.: 3"(76mm+/-1)

5. Similar products & guide

(1) DFC1001: Double sided aluminum foil supply better perfomance and function.

(2) FSK7160-P, perforate the FSK7160 as to absorb acoustic

- Q: How do I find roofers who are specialised in protection against invaders from outer space. I called 10 and they said they would call me back, but no one did so far. It must be really complicated.

- yes it does, only if aliens truly existed have you ever stopped to think that some of these strange flying objects maybe be a VERY TOP SECRET military project, the goverment might be paying millions to the media and people so that they assume its from outer space so that their projects remain secret

- Q: were can i buy material to insulate pans and instructions to install it? I have seen many roofs with this done ,but , the lowe,s and home depots don't have .

- you do now not desire insulation for this application. in case you have now not offered the metallic yet i might advise searching for a status seam roof equipment that the panel would not are available touch with the substrate and would not use uncovered fasteners. If contained sooner or later you probably did be certain to surround the porch and upload warmth you ought to insulate the ceiling and depart an air area below the decking that ought to be ventilated from the eave to the ridge. a chilly roof assembly with proper air flow will dramatically cut back the flexibility of the metallic panels sweating.

- Q: Help please, this home had a water pipe from meter brake in the basement as it was unoccupied/empty, the owner/builder replaced all the drywall, insulation, flooring, carpet, tile, roof, windows, hot water tank, furnace, bathroom and kitchen cabinets, new paint on all, basement ceiling was spray painted black (to hide something or to seal it?). the neighbor says the home was gutted and mold tested three times, its completely redone basically a new home inside, feedback please, it "looks" great

- Hi there. I suggest that you require a home inspection, a mold test and termiite treatment before buying the house. If it was tested, the seller should be able to provide the results. Anytime that there is severe water damage, mold and termite issues usually follow. It is better to be sure that everything is okay before you buy the house.

- Q: I live in central florida. I plan on installing R-30 insulation to the floor of my attic. How effective is it to install reflective insulation to the attic on the roof side? Is it worth the price?

- do not insulate your roof,it will cause the roof to get VERY hot,this will damage the roofing,shorten its life,,the temp in your attic should be within 3-4 deg of outside temp,,,insulate the floor Only and have plenty of ventilation

- Q: on a traditional pitched roof construction,where is heat insulation usually provided?

- On the ceiling.Paper side down to help protect against moister.

- Q: Foam and the new building technolodgy's are coming to New Orleans. The rebuilding is causing New Orleans to be the "Greenest City in America". Energy Efficiency and the proper buiilding techniques tak hold.

- First, "green" building is not technically defined as far as the construction industry is concerned. i.e. anyone can call their products "green" until the parameters are set up to strickly define what is "green" and what is not. To date, it's been more of a marketing strategy than anything. (Unless this has changed in recent months) I'm glad to hear New Orleans is taking the right path in rebuilding the place! Hope to get back down there soon.

- Q: Rather than waste that heat on sunny days during the heating season, can it be used to help heat the home? Otherwise it would just passively be vented out. Has anyone done this? Is it a good idea or not?

- should work, heat pumps pull the heat out of the air,

- Q: I am purchasing a mobile home with a shingled roof. The shingles need to be replaced (>15yrs old) and with the cost of heating going up each day I thought I would added some of that 2" thick rigid insulation. I would place this right on top of the existing roof and then place the firring strips for the metal roof right on top of the rigid insulation panels (which are 4x8'). By using 3" galvanized sheet rock screws I will get a good solid attachment. Then I will put the metal roofing on to the firring strips as normal. Does anyone see any downside to doing this? Has anyone tried this before?

- I agree with the soundness of every part of your plan EXCEPT not removing the original shingle roof. The shingle roof is already at the end of its usable life. There’s no benefit to covering up old problems, and they will most likely affect the durability of the new roof. Plus, removing the old roof gives you the opportunity to inspect and repair any issues with the roofing deck. Your new insulation and metal roof will attach better and perform better by removing the old shingle roof.

- Q: I've found lots of building forums and general "building advice" columns that go over very high-level pros/cons to choosing roofing material and insulation options, but I want a site where I can see hard costs of ordering each of the materials so I don't have to call up a ton of contractors or dealers. Does such a comparison site exist? Everyone offers quotes, but that takes too much time to apply for quotes to every dealer.I'm specifically interested in knowing what green options I can afford (cotton batting vs. formaldehyde-free fiberglass, etc.).

- It's in euro's but you can convert or get the idea. Also, you have to click on the graphs to get a more clearer image.

- Q: fixing my room up and it gets hot in summer so i want to put some good insulation in the roof so what could i use?

- if you are going to put in insulation put in the roll kind. it will be very easy and less expensive

Send your message to us

FSK Roofing Insulation Adhesive Heat Insulation Materials

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords