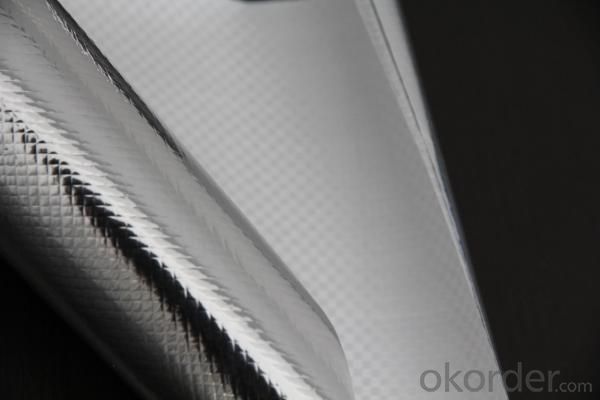

TPO Roofing Insulation Single Side Woven Foil FPC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 20 Tons Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of FPC

Construction:

Aluminum foil: Aluminum: 7u / Polyethylene / Polyethylene Woven Fabric

Typical Physical Properties:

|

PROPERTIES |

UNIT |

VALUE |

TEST METHOD | ||||

|

Basic weight |

gsm |

110 |

ASTM D646 | ||||

|

Tensile strength: M. D. X. D. |

N/25mm |

400 400 |

ASTM C1136 | ||||

|

Burst strength |

N |

140 |

ASTM D774 | ||||

|

Reflectivity of foil surface |

% |

95 |

---------- | ||||

|

Temp. Resistance |

-29°C +66°C |

No change keep soft |

ASTM C1263 | ||||

|

Water vapor permeance |

ng/N.s |

1.6 |

ASTM E-96 | ||||

|

Water Soak Test |

24hrs |

No delamination |

---------- |

Width: 1.2m, 1.25m, 1.3m,1.5m

Length: 60m, 100m, 120m

Core I.D.: 3"(76mm ±1)

Based on order, special sizes are also available.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm;

Length: Cut Roll & Log Roll ±0.3m, Jumbo Roll ±0.5%.

3. The products should be stored at room temperature and kept from wet and heat source.

4. It is essential, as with all pressure-sensitive tapes, that the surface to which the tape is applied must be clean, dry, and free of grease and oil.

5. The user should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for user’s special purpose and technique.

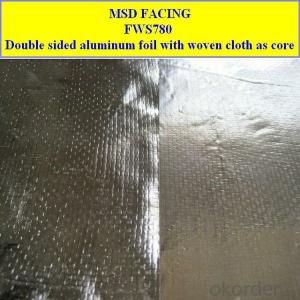

2. Usage/Applications of FPC

Double sided aluminum foil vapor barrier, whose structure is aluminum foil/ high strength kraft/fiberglass scrim/aluminum foil and laminated together by special flame retardant adhesive, can be used for roofing, wall insulation of house, warehouse, cold storages, factory and others.

3. Packaging & Delivery of FPC

Each roll is packed by kraft paper than put on the pallets.

- Q: Should a two story home have insulation under the roof in the big closets ?

- yea. it might cost you some to put it in but it will save you a lot in the future with heating and air conditioning bills

- Q: the roof of my mouth hurts bad.i worked all day with sawdust and insulation yesterday.is this the problem.?

- it is what might have irritated your mouth. use a mask in the future. for now, increase your fluid intake and try Benedryl for a few days.

- Q: I do not have extra space on the roof. Roof also tapers to drains at one end of building.

- Nope. The DOW rigid insulation is an R-5/inch. So 4 inches gets you an R-20. Sorry.

- Q: 1) What thickness of rigid insulation is used on flat roofs?

- I've seen as little as 2" and as much as 8".

- Q: p/t deck on a commercial rubber roof do we need closed cell insulation under deck to protect rubber?

- You don't need it to protect the rubberoid roof however considering the relatively low cost of the closed cell foam it would be cheap insurance to add it. A more pressing concern would be the drainage details.

- Q: if you had snow and all the snow is off your roof and the house nex store has snow do we need insulation?

- That is very observant of you. Yes this could indicate that you are losing more heat than normal through your roof. Though, you do want to be careful in the placement of any new insulation, you will want to avoid any vents that are there for ventilation of heat and moisture in the summer and any recessed lighting fixtures as to not cause an overheating problem with them. This is a good investment and it will pay you back in heating and cooling cost for years to come.

- Q: roof was replaced eight years ago soon after there were leaks in the roof caused insulation toget wet then dry now the insulation is packed hard and has started to turn into power who would be responsible to replace the insulation.

- Sorry; I don't know of any roofer that would take responsabilty after eight years. Unless your insurance might be an option. Check with them and decide if your deductable is more than the repair if you would be better off doing it yourself. I would also be concerned about underlying materials, sheet rock, lumber, MOLD. You need someone to check thoroughly for mold being as it has been so long. GOod luck; Flip;

- Q: So I'm renovating an old farmhouse with a metal roof and there is no insulation in the attic. I was up in the attic checking for leaks since we just got some freezing rain and it is currently melting I thought now was the perfect time to check. I found no leaks but I did notice the roof was sweating with noticeable beads of water in many places and many of the 2x4's that act as the frame were damp, although none were rotted (I found that odd as the house is approx. 140 years old and those are the original 2x4's. I could tell that the attic does have vents so I guess it dries out before rotting or mold occurs.. but makes me wonder if I put down some roll-in faced R-30 Owens Corning Insulation and then add a plywood floor over top if everything will be fine.. or not so fine..

- Hi, GA. On my second coffee here, so bear with me if a little fuzzy. Trying to envision what you're looking at, first thing I hear is 2x4 roof framing, not say the 2x6 or 2x8 rafters I would expect. A 2x4 structure and metal roof is a light build more suitable for a shed or outbuilding than a home. Wouldn't tolerate much additional weight, like from plywood. Next thing, which I don't hear, is whether there's moisture on the attic's "floor", where you're standing. I'm thinking the moisture you're noting is above you, on the undersurface of the roofing, and on the rafters. Finally, while some condensation on the underside makes sense, it would also seem quite possible that there are a number of small leaks through the roof. My goals would be to first ensure there are no leaks through the roof surface, then to ensure the attic indeed has enough venting, then to both reduce air from the lower living level bleeding through up to the attic space (also good to reduce convective heat loss), then to insulate the attic floor to reduce radiant heat loss from below and warming of the attic air, pretty much in that order. The prize is a leak-free roof over a cold attic space.

- Q: we have liq. ammonia storage tank (capacity 40000 ton)having double wall & suspended deck.liq. NH3 stored at temp -33 degree cent. insulation (form ) being provided to annular space (wall ) but not on top roof . can you explain for exact reason.with regardsanvar shaikh

- Insulation is less necessary on the roof. The ammonia is mostly a liquid, and a liquid would absorb heat rapidly from tank walls. Above the liquid is vapor, and vapor absorb heat much less rapidly than liquid does, so insulation is less important there.

- Q: i have about 200 sq ft of odd shaped polystyrene foam (rigid) insulation between 3" and 5" thick. it's leftover from installing a flat roof on a commercial building. creative ideas anyone? grind it and use it as attic insulation in a home?thanks.

- I'm a bit confused here Andy. If the flat roof needs replacing, when it is removed what is revealed is going to be exactly what you would see if you removed the ceilings. So why consider removing the ceilings if they are ok? When the flat roof is replaced put the insulation in then. Whilst rockwool would have been the material to use there is now roofing insulation board that is much more efficient, 50mm board gives equivalent insulation of something like 150mm rockwool. If the flatroof isn't fitted with suitable vents to keep it ventilated fit them when the roof is done too. The only reason I can see for replacing the ceiling plasterboard is if it hasn't got a vapor barrier ie foil backed board.

1. Manufacturer Overview

| Location | Zhejiang, China |

| Year Established | 2004 |

| Annual Output Value | Above US$ 0.2 billion |

| Main Markets | 20.00% Mid East 15.00% Northern Europe 15.00% North America 12.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 4.00% Oceania 3.00% Western Europe 2.00% Southern Europe Mid East;South east asia;North America |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

TPO Roofing Insulation Single Side Woven Foil FPC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 20 Tons Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords